Sponge city high-strength recycled aggregate concrete and preparation method thereof

A recycled aggregate and sponge city technology, applied in the field of building materials, can solve the problems of performance degradation of recycled aggregate concrete, and achieve performance improvement, stability, compressive strength, and slow performance decay rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

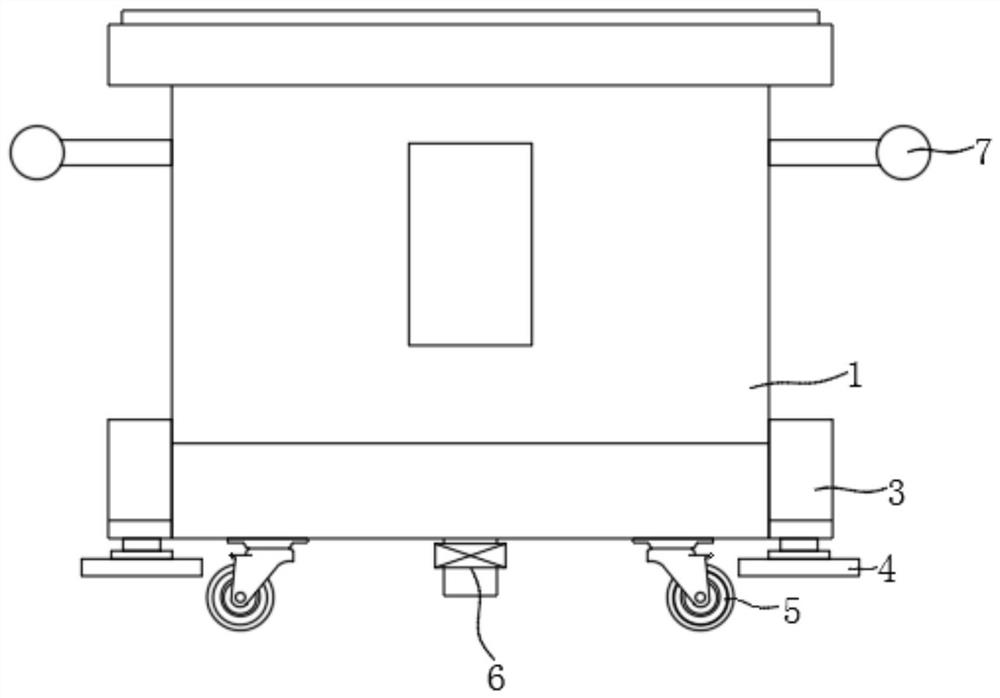

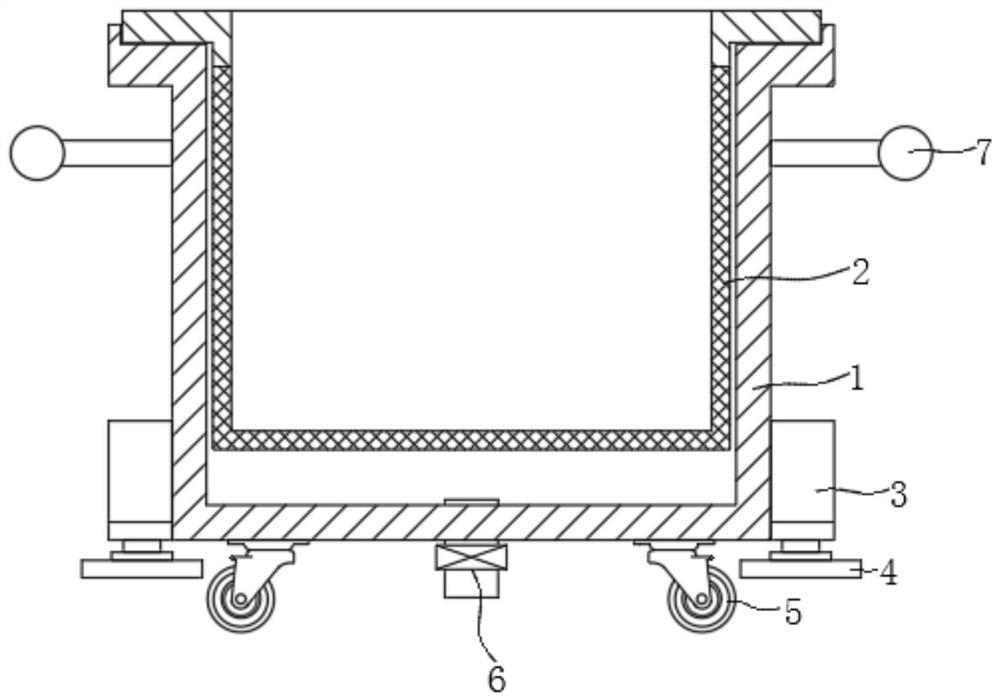

[0047] Please refer to figure 1 and figure 2 ,in, figure 1 Schematic diagram of the external structure of the soaking device provided by the present invention; figure 2 for figure 1The schematic diagram of the internal structure of the body is shown. Sponge city high-strength recycled aggregate concrete, including the following raw materials in parts by weight:

[0048] 600 parts of the reinforced recycled coarse aggregate, 400 parts of cement, 100 parts of water, 50 parts of steel slag powder, 35 parts of limestone powder, 30 parts of nano silicon dioxide, 20 parts of graphene oxide powder, 15 parts of polyacrylate, water glass 10 parts, 5 parts of water reducing agent, 4 parts of superabsorbent resin, 6 parts of modified reinforcing agent;

[0049] Wherein, the modified reinforcing agent includes the following raw materials in parts by weight:

[0050] 15 parts of nano-calcium carbonate, 12 parts of polyvinyl alcohol, 8 parts of diboron trioxide, 4 parts of aminotrim...

no. 2 example

[0071] Based on the first embodiment of the present invention, a sponge city high-strength recycled aggregate concrete and its preparation method, the second embodiment of the present invention provides another sponge city high-strength recycled aggregate concrete and its preparation method, wherein the first The second embodiment does not hinder the independent implementation of the technical solution of the first embodiment.

[0072] Specifically, the present invention provides another sponge city high-strength recycled aggregate concrete and its preparation method with the following differences:

[0073] Reinforced recycled coarse aggregate 700 parts, cement 500 parts, water 150 parts, steel slag powder 70 parts, limestone powder 55 parts, nano silicon dioxide 45 parts, graphene oxide powder 30 parts, polyacrylate 25 parts, water glass 17 parts , 8 parts of water reducing agent, 6 parts of superabsorbent resin, 9 parts of modified reinforcing agent;

[0074] Wherein, the m...

no. 3 example

[0093] Based on the first embodiment of the present invention, a sponge city high-strength recycled aggregate concrete and its preparation method, the third embodiment of the present invention provides another sponge city high-strength recycled aggregate concrete and its preparation method, wherein the first The three embodiments do not hinder the independent implementation of the technical solution of the first embodiment.

[0094] Specifically, the present invention provides another sponge city high-strength recycled aggregate concrete and its preparation method with the following differences:

[0095] Comprising the following raw materials in parts by weight:

[0096] Reinforced recycled coarse aggregate 800 parts, cement 600 parts, water 200 parts, steel slag powder 100 parts, limestone powder 70 parts, nano silicon dioxide 60 parts, graphene oxide powder 40 parts, polyacrylate 30 parts, water glass 15 parts , 10 parts of water reducing agent, 8 parts of superabsorbent re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com