Heat-conducting silicone grease with gradually-increased heat conductivity coefficient and preparation method of heat-conducting silicone grease

A technology of thermal conductive silicone grease and thermal conductivity, which is applied in the direction of chemical instruments and methods, heat exchange materials, etc., can solve the problems of limited thermal conductivity, limited filling rate of thermal conductive powder, etc., and achieve good high temperature stability, excellent electrical properties, Easy construction and shaping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

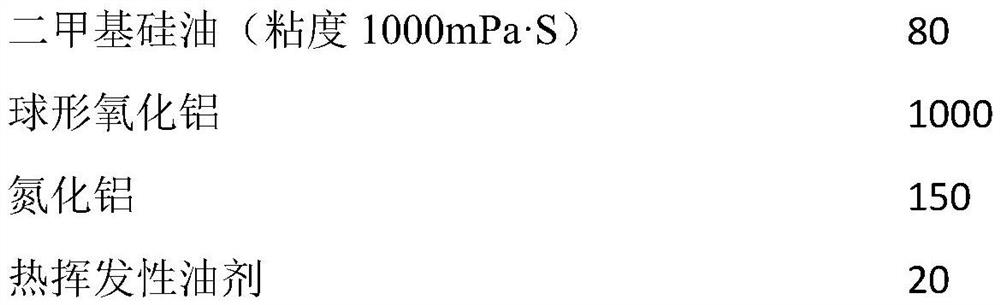

[0021] 1. A heat conduction coefficient of heat conductive dielectric is accumulated in the present embodiment, and the raw material group is:

[0022]

[0023] in:

[0024] The spherical alumina (1 to 5 μm particles) and aluminum nitride (3 to 6 μm having a particle diameter) were surface treated using hexamethililazine (the powder was treated under 80 ° C for 2 h, and then cooling) By 35 ~ 40 ° C, surface treatment is performed using hexamethilic siliconzine.

[0025] The thermal volatile oil is food grade white oil, its viscosity is 25 mPa · s, and the pH is determined by a pH of 7 ± 0.3.

[0026] 2, the present embodiment has the preparation method of the heat conductive silicone fat, the steps are as follows:

[0027] (1) First, the above silicone oil and a portion of the spherical alumina (70% by weight thereto) were stirred at a stirring speed of 30 Hz, and then the remaining spherical alumina was added to continue stirring at a stirring speed of 35 Hz, and mixed for 10 m...

Embodiment 2

[0031] 1. A heat conduction coefficient of heat conductive dielectric is accumulated in the present embodiment, and the raw material group is:

[0032]

[0033] in:

[0034] The spherical alumina (1 to 5 μm particles) and aluminum nitride (3 to 6 μm having a particle diameter) were surface treated using hexamethililazine (the powder was treated under 80 ° C for 2 h, and then cooling) By 35 ~ 40 ° C, surface treatment is performed using hexamethilic siliconzine.

[0035] The thermal volatile oil is food grade white oil, its viscosity is 25 mPa · s, and the pH is determined by a pH of 7 ± 0.3.

[0036] 2, the present embodiment has the preparation method of the heat conductive silicone fat, the steps are as follows:

[0037] (1) First, the above silicone oil and a portion of the spherical alumina (70 wt% thereof) were stirred at a stirring speed of 35 Hz, and then the remaining spherical alumina was added to continue stirring at a stirring speed of 30 Hz for 10 min, resulting in a...

Embodiment 3

[0041] 1. A heat conduction coefficient of heat conductive dielectric is accumulated in the present embodiment, and the raw material group is:

[0042]

[0043] in:

[0044] The spherical alumina (1 to 5 μm particles) and aluminum nitride (3 to 6 μm having a particle diameter) were surface treated using hexamethililazine (the powder was treated under 80 ° C for 2 h, and then cooling) By 35 ~ 40 ° C, surface treatment is performed using hexamethilic siliconzine.

[0045] The thermal volatile oil is food grade white oil, its viscosity is 25 mPa · s, and the pH is determined by a pH of 7 ± 0.3.

[0046] 2, the present embodiment has the preparation method of the heat conductive silicone fat, the steps are as follows:

[0047] (1) First, the above silicone oil and a portion of the spherical alumina (70 wt%) were stirred at a stirring speed of 30 Hz, then the remaining spherical alumina was added to continue stirring at a stirring velocity of 40 Hz for 15 min, resulting in a mixture;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com