Repair factor-loaded suture line production device

A technology for repairing factors and production devices, which is applied in the fields of filament generation, final product manufacturing, and textile material carrier processing, which can solve problems such as excessive drug intake side effects, secondary damage to skin tissue, and poor therapeutic effects, and achieve improved release The effect of speed, increase of contact area, and relief of pain symptoms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

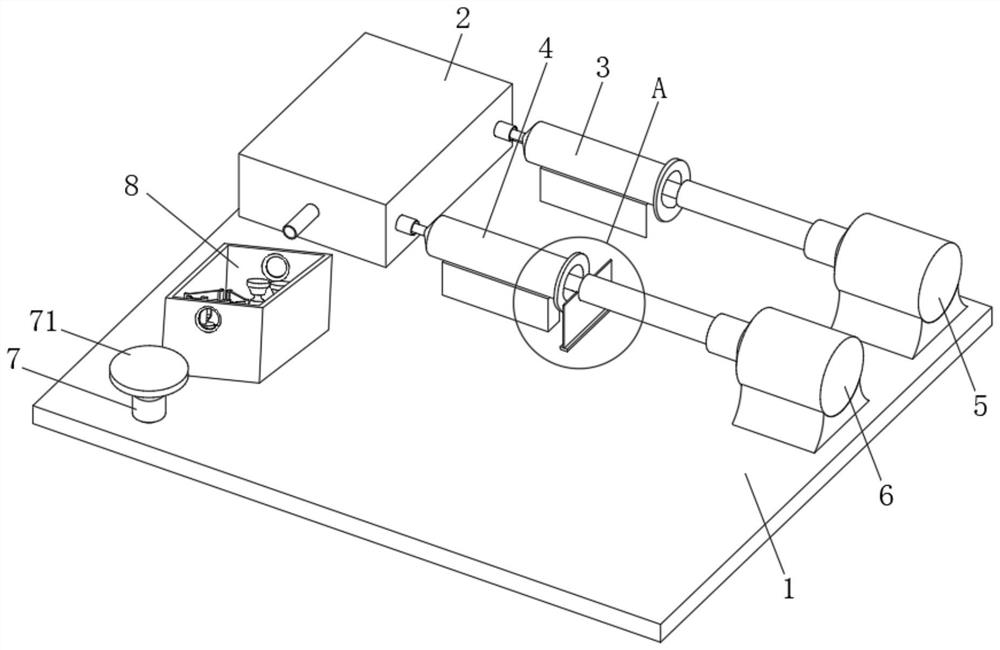

[0034] see figure 1 and figure 2 , a suture production device loaded with repairing factors, including a base plate 1, a spinning device 2 is fixed on the top of the base plate 1, a material outlet is opened on the front side of the spinning device 2, two material inlets are opened on the right side, and a built-in 5kV The power supply, the two feed inlets of the spinning device 2 are respectively connected to the discharge end of the spinning solution injector 3 and the repair factor injector 4, the repair factor injector 4 internal solution contains repair factors or nanoparticles, and the repair factors or nanoparticles can be Restoration drugs, anti-inflammatory drugs, repair proteins and other substances, the bottoms of the spinning solution syringe 3 and the repair factor syringe 4 are fixed to the top of the base plate 1, and the driving pistons inside the spinning solution syringe 3 and the repair factor syringe 4 are respectively connected to the push pump-5 It is f...

Embodiment 2

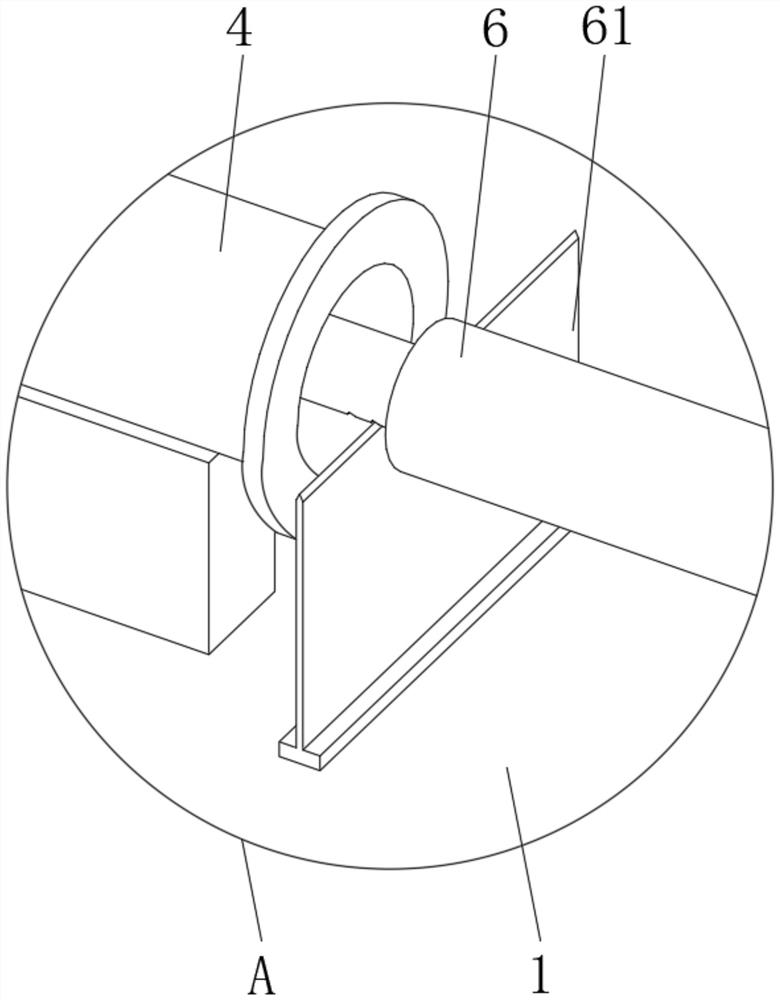

[0038] see figure 1 and figure 2 , on the basis of Example 1,

[0039] In this embodiment, in order to make the suture thread in the shape of a core shell and the shell layer distributed in a discontinuous shape, the spinning solution inside the spinning solution injector 3 is a degradable fiber with elastic stretching effect, and the internal mixing solution of the repairing factor injector 4 also contains For polyglycolic acid, propulsion pump one 5 is a continuous propulsion pump, and propulsion pump two 6 is an intermittent propulsion pump.

[0040] In this embodiment, since the solution in the repair factor injector 4 is a repair factor or a mixture of nanoparticles and polyglycolic acid, the suture spun by the spinning device 2 is composed of the degradable fiber core layer of the spinning solution injector 3 and the repair factor. The degradable shell of the syringe 4 is composed of polyglycolic acid as the carrier of the repair factor or nanoparticles, which can imp...

Embodiment 3

[0042] see Figure 3-4 , on the basis of Example 2,

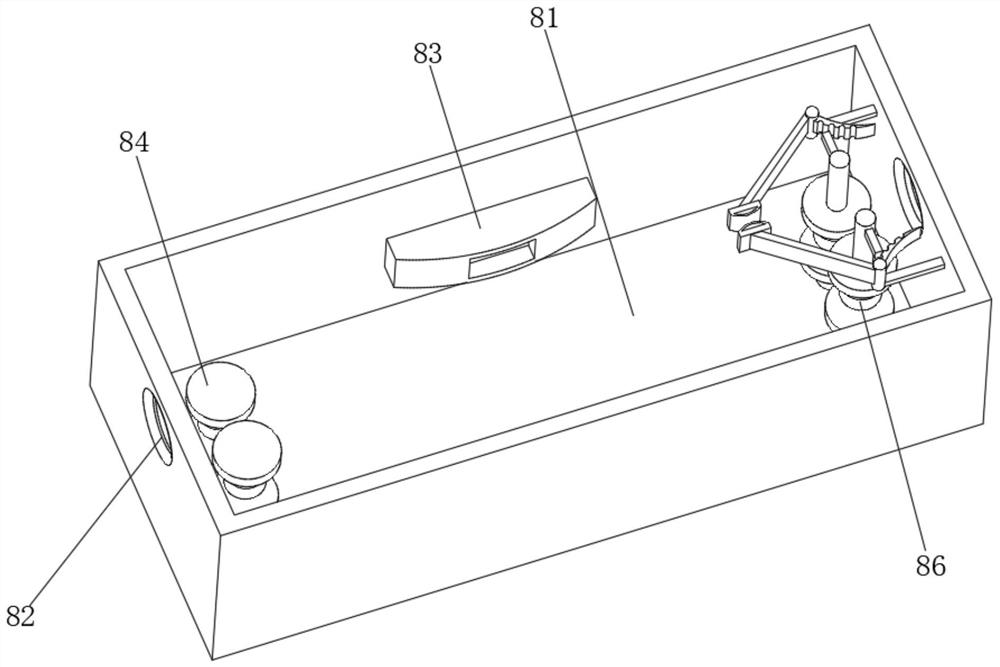

[0043] A suture production device carrying a repair factor, the part between the outlet of the spinning device 2 and the winding wheel 71 is provided with a dipping mechanism 8, the dipping mechanism 8 includes a dipping tank 81, and the input end of the dipping tank 81 is provided with a conductive The front and rear sides of the wire groove 82 and the inside of the dip dyeing groove 81 are all fixedly connected with an air bag 83 , and the inside of the dip dyeing groove 81 and one end close to the conductive wire groove 82 is rotatably connected with a guide wheel 84 .

[0044] A discharge port 85 is provided at the output end of the dipping tank 81 and corresponding to the conducting wire slot 82 , and a limiting wheel 86 is provided inside the dipping tank 81 and near the discharge port 85 . The suture is input from the conduction line groove 82 to the inside of the dipping tank 81, and the dipping tank 81 stores the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com