Lithium bromide air conditioning system integrality optimization control method and system

A technology for optimizing control and air conditioning systems, applied in air conditioning systems, space heating and ventilation, heating and ventilation control systems, etc., and can solve problems such as energy waste and waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] A lithium bromide air conditioning system integrity optimization control method, comprising the following steps:

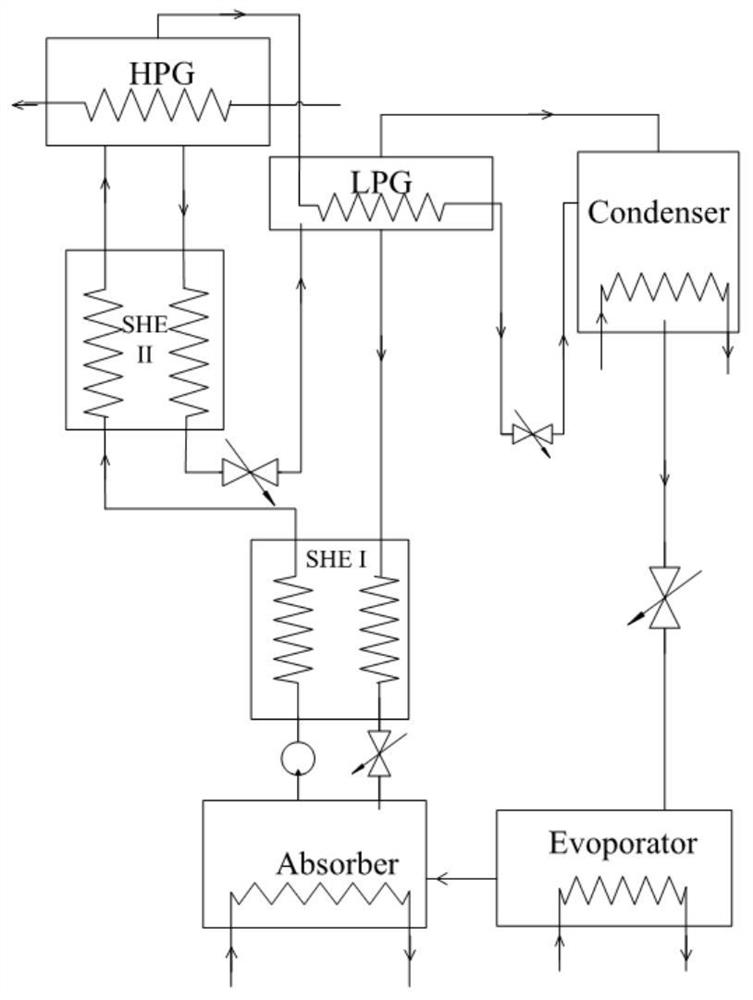

[0071] Step 1) set up the model of each component of lithium bromide unit, comprise high pressure generator model, low pressure generator model, absorber model, high temperature solution heat exchanger model, low temperature solution heat exchanger model, evaporator model and condenser model;

[0072] Step 2) based on the model of each component of the lithium bromide unit, obtain the operating data of the actual lithium bromide unit, and establish the variable working condition simulation model of the lithium bromide unit based on the operating data;

[0073] Step 3) set up cooling tower model;

[0074] Step 4) Coupling the cooling tower model and the variable operating condition simulation model of the lithium bromide unit to obtain a complete lithium bromide refrigeration system, with the cooling water flow and the cold water flow as parameters to be opt...

Embodiment 2

[0077] A lithium bromide air conditioning system integrity optimization control method, comprising the following steps:

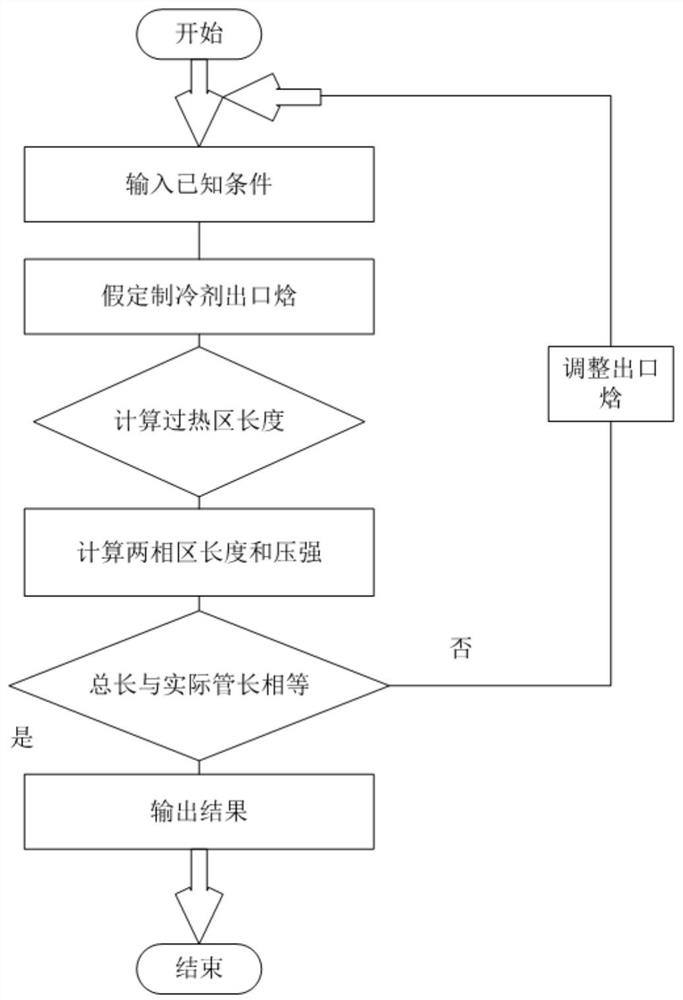

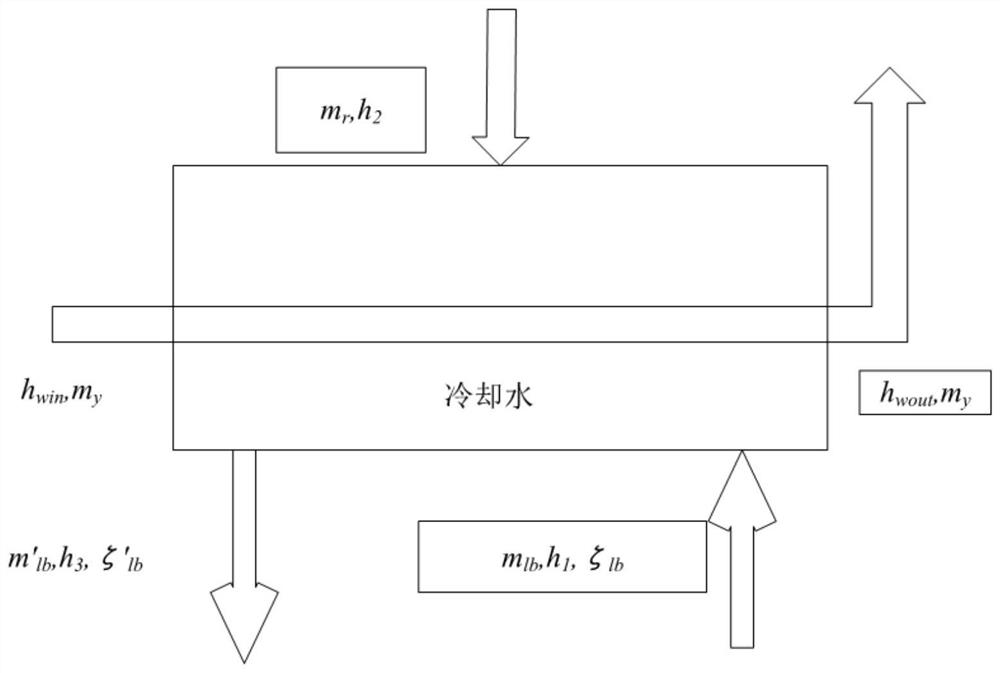

[0078] S1. For the lithium bromide unit, the model is divided into components, and then the idea of coupling the internal components is adopted. The coupling diagram is as follows figure 1 As shown, where the steady-state distribution parameter model is used for the evaporator, the heat transfer process of the evaporator can be expressed as (the condenser model is the same), the principle is as follows figure 2 Shown:

[0079] m q C p (t q2 -t q1 ) = θm z (h z1 -h z2 ) (1)

[0080] Among them, m q is cold water flow / kg s -1 ;C p Specific heat capacity / kJ (kg K) -1 ;t q2 is the outlet temperature of the refrigerant / °C; t q1 is the evaporation temperature / °C; θ is the heat dissipation coefficient; m z is the flow rate of refrigerant / kg·s -1 ; h z1 Enthalpy value of refrigerant inlet / kJ kg -1 ; h z2 Enthalpy value of refrigerant outlet / kJ...

Embodiment 3

[0185] For the following lithium bromide air conditioning system: the design parameters are shown in Table 1.

[0186]

[0187]

[0188] Assume that the load on a certain day is:

[0189]

[0190] Bring the above data into the optimal control method of the lithium bromide air conditioning system, and combine it with the local air temperature before heat exchange of 30°C.

[0191] Use the optimization algorithm to calculate the optimal cooling water flow and the cooling water flow as:

[0192] time Cooling water side flow / kg·s-1 Cold water flow / kg·s-1 8:30 52.16 68.78 9:30 53.45 69.70 10:30 53.34 69.40 11:30 52.56 69.05 12:30 52.48 69.26 13:30 51.49 69.12 14:30 51.71 68.69 15:30 51.39 68.91 16:30 52.36 68.76

[0193] Using the optimization algorithm to calculate the temperature difference between the optimal cooling water side and the cooling water side is:

[0194]

[0195]

[0196] Applyi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com