Conductor cable for wind power generation tower drum

A conductor cable and tower technology, applied in power cables, conductors, insulated cables, etc., can solve problems such as increased maintenance costs, frequent wind farm accidents, cable lightning strikes, vibration, high and low temperature changes, sunlight aging, etc. The failure rate, low friction coefficient, and the effect of being conducive to narrow space laying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

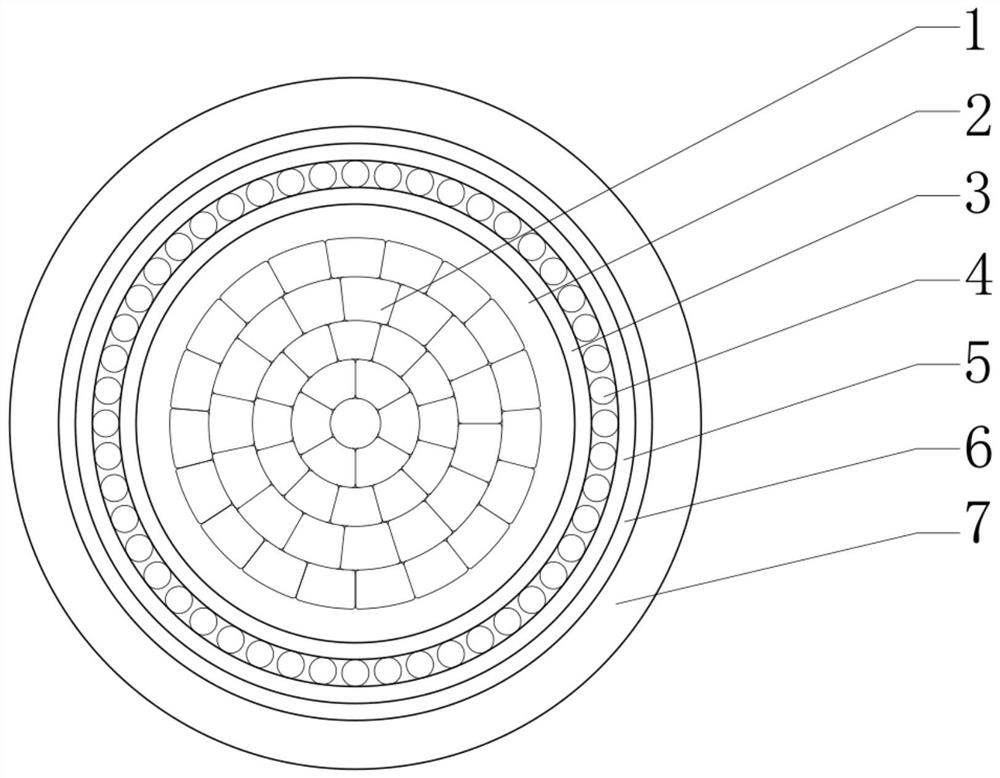

[0033] Cable model specification: FDT-WDZC-YJLHE 1.8 / 3kV 1×400mm 2

[0034] Cable process flow: aluminum alloy rod→shaped wire drawing→shaped wire stranding→aging annealing→insulation extrusion→wrapping / shielding→sheath extrusion.

[0035] Cable structure:

[0036] 1) Conductor: The conductor structure conforms to the requirements in Table 1, and the conductor is a stranded wire structure; the chemical composition of the conductor shall comply with the alloy chemical composition of any serial number specified in Table A.1 in Appendix A of GB / T 31840.1-2015; the conductor stranded The tensile strength of the combined single wire is 98 ~ 159Mp, the elongation at break is greater than 10%, and the DC resistance of the conductor at 20°C should meet the requirements of GB / T3956.

[0037] 2) Insulation: Cross-linked polyethylene insulation material is used, and the insulation performance and nominal thickness meet the requirements of GB / T31840.1.

[0038] 3) Shielding: Aluminum a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com