Special-structure environment-friendly power cable for transformer connection

An environmentally friendly technology for power cables, applied in the field of 12/20kV and above power cables, can solve the problems of waste of resources, low utilization rate of conductor interface, etc., to avoid conductor burrs, improve heat dissipation effect and current carrying capacity, and increase contact area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with example the present invention is described in further detail.

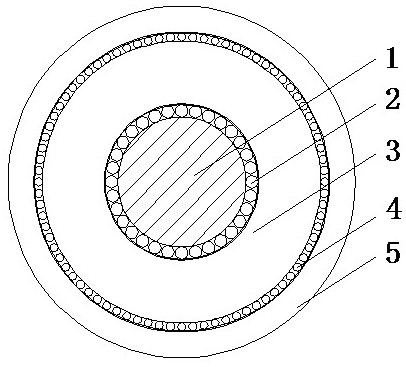

[0013] Such as figure 1 As shown, this embodiment describes a special structure environment-friendly power cable for transformer connection, the voltage level of this cable is 12 / 20kV, and the nominal cross-sectional area is 50mm². The special structure environment-friendly power cable for transformer connection, from the inside to the outside, is: composite structure filling core 1, concentric conductor 2, XLPE insulation layer 3, composite shielding layer 4, low-smoke halogen-free sheath 5. The filling core is located at the center of the cable, and the concentric conductor, XLPE insulation layer, composite shielding layer and low-smoke zero-halogen sheath are laid out layer by layer. Among them, the composite structure filling core 1 is made of 10 pieces of 1000 Dan Kevlar fibers extruded into an environmentally friendly low-smoke, halogen-free and flame-retardant polyolefin ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com