Bin top type pulse back-blowing dust remover

A pulse backflushing, dust collector technology, applied in chemical instruments and methods, separation methods, loading/unloading, etc., can solve problems affecting product reputation and downstream product quality, limited petrochemical work site space, and fire discharge. , to achieve the effect of good cleaning effect, high degree of automation and high kinetic energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

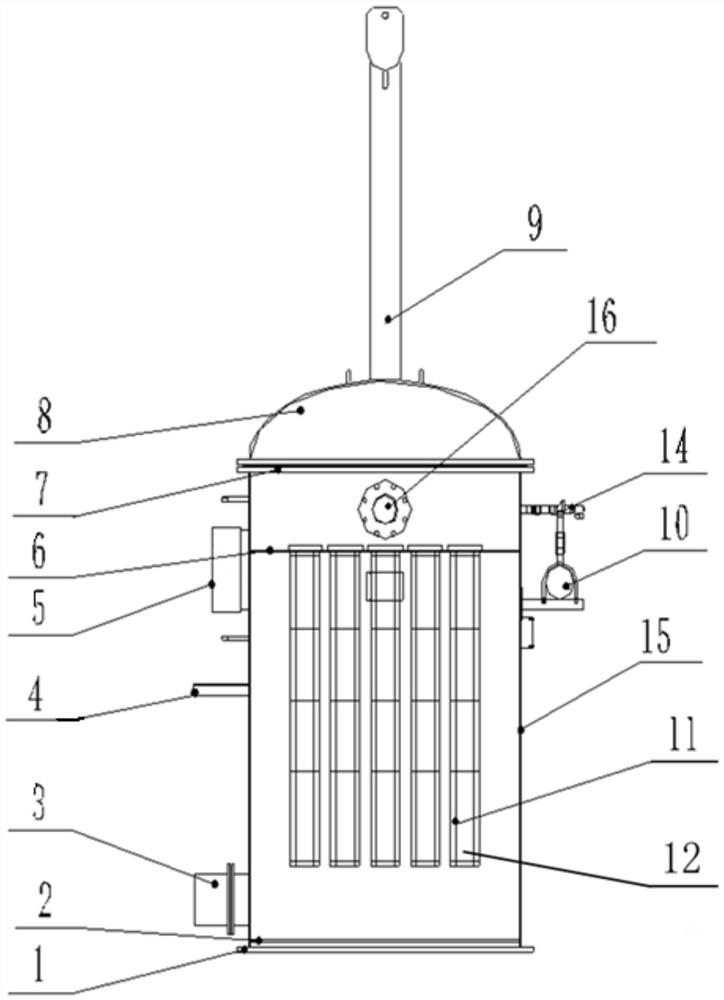

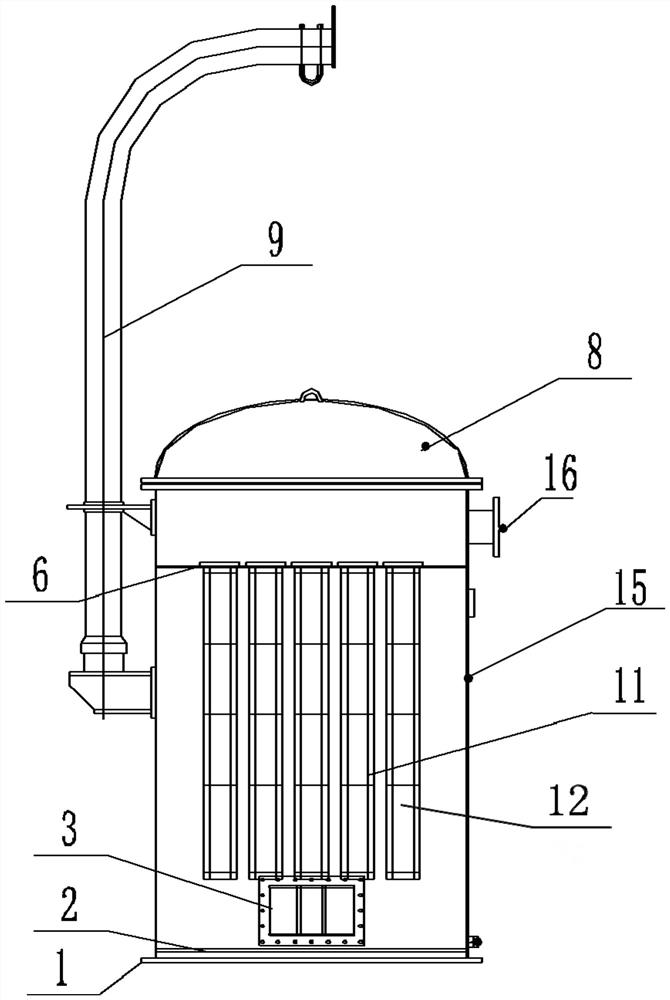

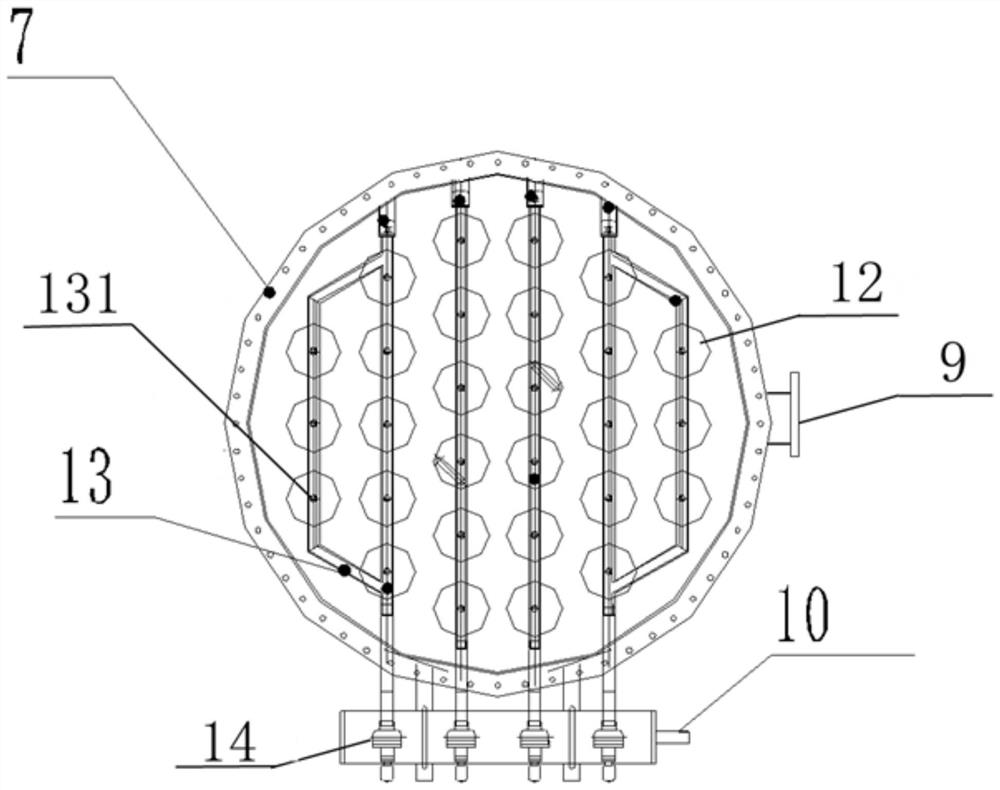

[0035] Such as Figure 1-3 As shown, the present invention proposes a warehouse-top type pulse blowback dust collector, including a housing, a filter chamber, a clean air chamber, a security system, and a dust removal system;

[0036] The shell includes a large bottom flange 1, a cylinder body 15, a flower hole plate 6, a large top flange 7, a head 8, and a suspension column 9. The cylinder body 15 is arranged between the top flange 7 and the bottom flange 1, and is cylindrical. structure, the perforated plate 6 is arranged inside the cylinder body 15, and the bottom end of the cylinder body 15 is provided with an air inlet for the dusty gas to enter the dust collector. In order to prolong the service life of the filter bag 12 in the filter chamber, the flow rate of the dusty gas needs to be Below 0.8m / min, there is a steel grid 2 above the air inlet, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com