Mixing device for preparing composite passivator applied to heavy-metal-contaminated soil and using method thereof

A technology of polluted soil and material mixing device, which is applied in the restoration of polluted soil, chemical instruments and methods, circuit devices, etc., can solve the problems of inconvenient raw materials, such as two-way rotation and agitation, continuous and uniform crushing and moving and uniform feeding, etc., to achieve Improve mixing efficiency and uniformity, and meet the effect of use requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

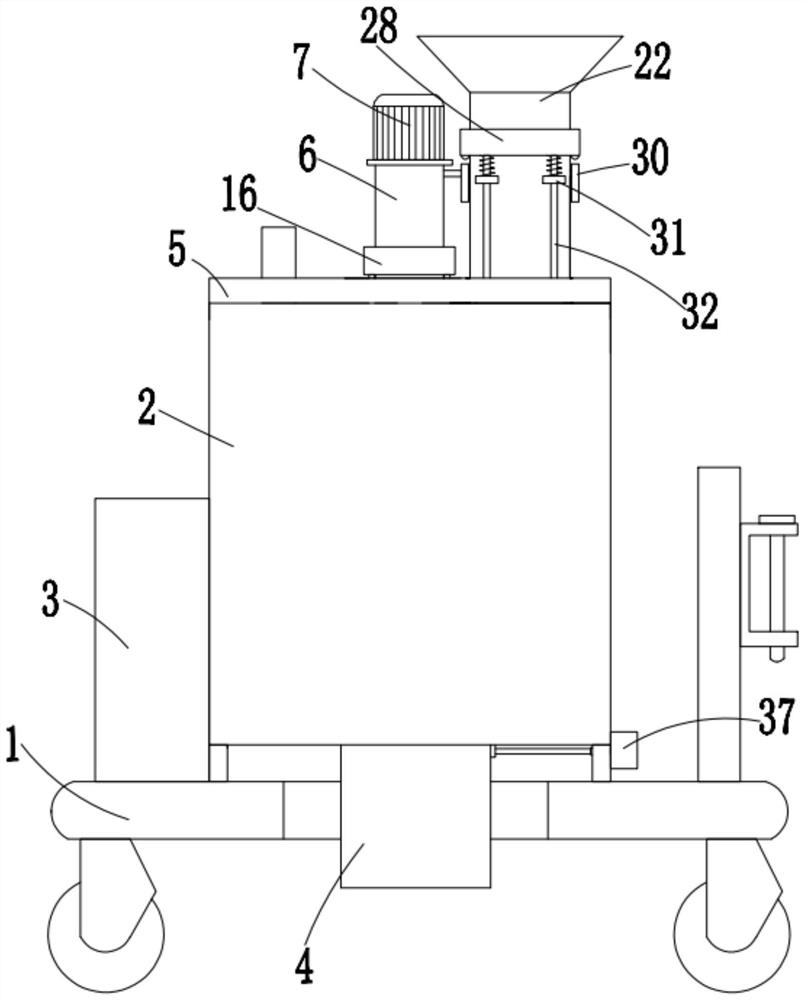

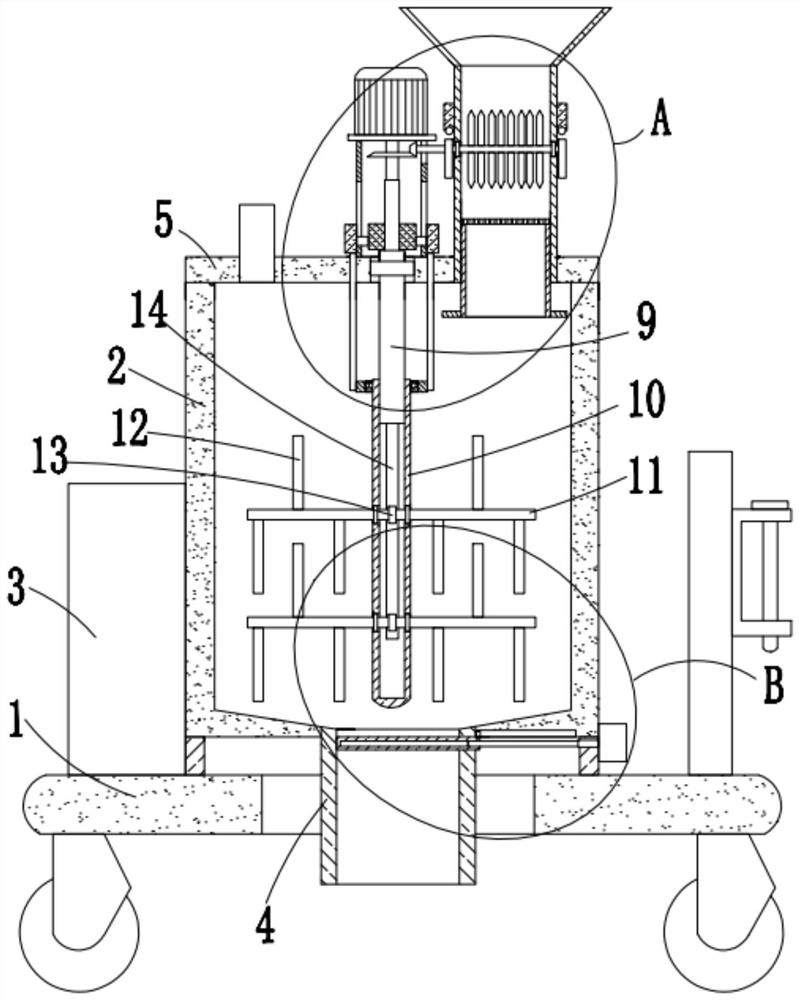

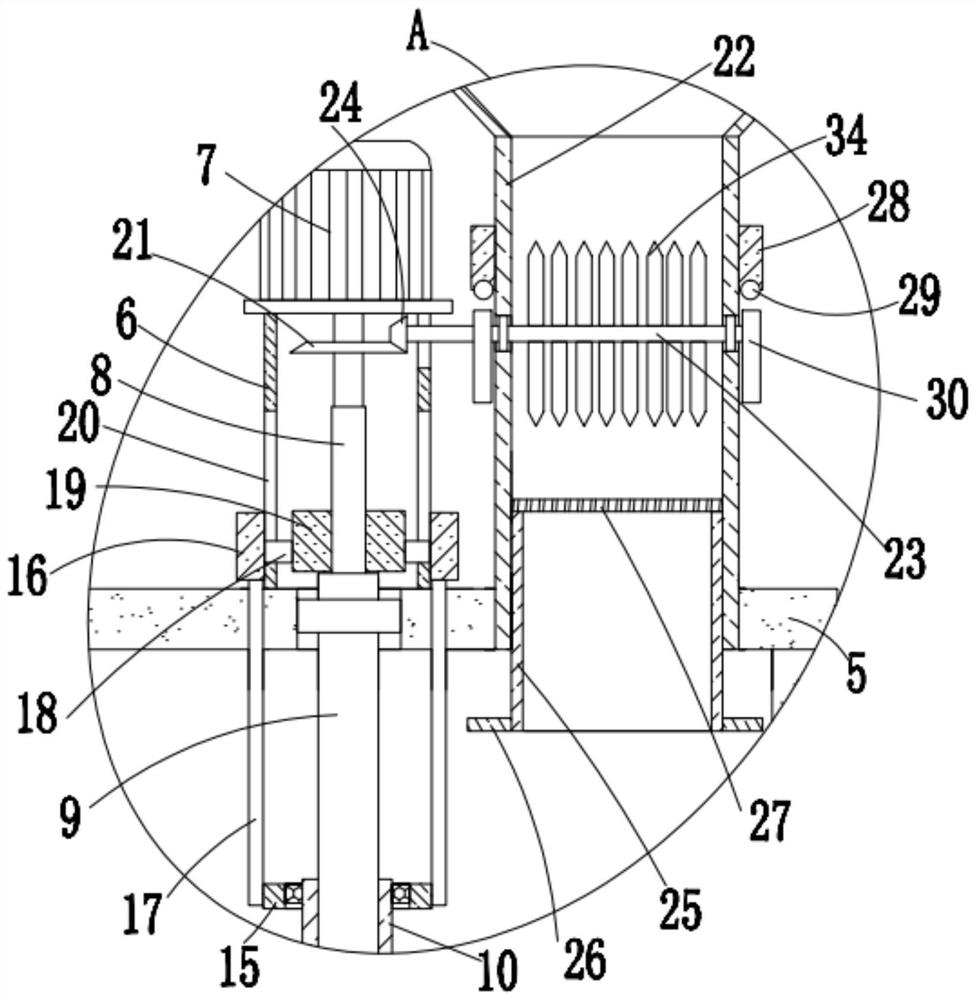

[0042] refer to Figure 1-7 , a mixing device for the preparation of a compound passivator for heavy metal polluted soil, comprising a mixing box 2 with an opening at the top, the top of the mixing box 2 is fixedly connected with a cover plate 5, and a feed circular pipe is embedded on the left side of the top of the cover plate 5 , both sides of the bottom of the mixing box 2 are fixedly connected with supports, the bottoms of the two supports are fixedly connected with the same U-shaped base 1, the top left side of the U-shaped base 1 is fixedly connected with the battery 3, the U-shaped base 1 The right side of the top is fixedly connected with a tractor connecting seat, and the four corners of the bottom of the U-shaped base 1 are rotatably equipped with traveling wheels. The tractor connecting seat, U-shaped base 1 and traveling wheels are used to facilitate the movement of the mixing device driven by an external tractor. The inner wall of the bottom of the mixing box 2 i...

Embodiment 2

[0055] refer to Figure 8-9 , the present embodiment is based on the first embodiment, and its difference from the first embodiment is that: the rectangular discharge pipe 4 is also provided with a dialing mechanism, and the dialing mechanism includes a rotating device mounted on the rear side of the rectangular discharge pipe 4. The rotating shaft 41 on the inner wall, and the inner wall on both sides of the rectangular discharge pipe 4 are in movable contact with a material-discharging circular tube 38, and the outer side of the material-discharging circular tube 38 is ring-shaped and equidistantly provided with multiple front and rear sides that are all openings. The top inner wall and the bottom inner wall of the round tube 38 are fixedly connected with support rods 40, and the two ends of the two support rods 40 are fixedly connected to the top and bottom of the rotating shaft 41 respectively. The rectangular discharge pipe The front side of 4 is fixedly installed with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com