Tape casting micro-dipping coating processing production equipment for composite membrane

A kind of production equipment and batch processing technology, applied in the direction of pretreatment surface, coating, surface coating liquid device, etc., can solve the problems such as poor coating effect, achieve good coating effect, ensure coating effect, Guarantee the effect of using the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

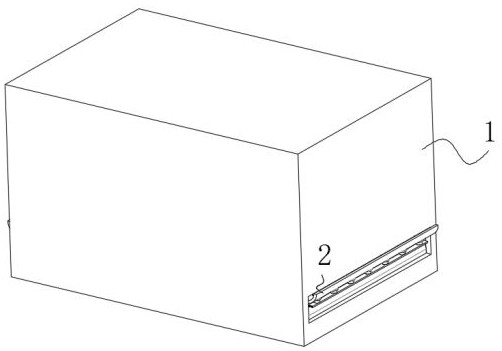

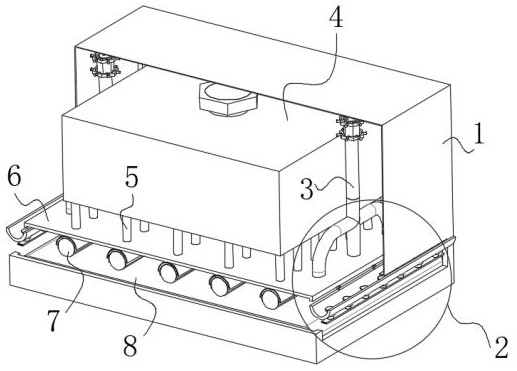

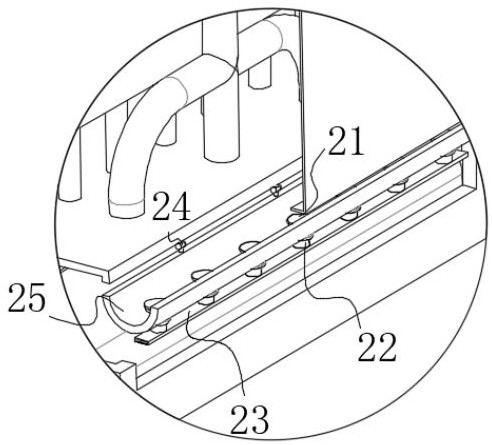

[0028] use Figure 1 - Figure 7 The casting microexal coating treatment production apparatus for a composite film according to an embodiment of the present invention is described below.

[0029] like Figure 1 - Figure 7 As shown, the cast film of the present invention includes the production apparatus including the outer casing 1, and both ends of the outer casing 1 are configured, and the purpose of setting the cleaning device 2 is to remove the composite film. The static electricity, thereby increasing the coating effect of the composite film, and the storage box 4 is provided inside the outer casing 1, and the back surface of the storage case 4 is fixedly connected, and the bottom portion of the storage box 4 is uniformly provided with the transmission tube 5, set the transmission tube. 5 Objective To ensure that the coating apparatus 7 can uniformly contain the batch feedstock, the top portion of the transmission tube 5 is fixed to the bottom of the storage tank 4, and the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com