Gluing process method for PET plastic film sticky notes with anti-wrinkling effect

A technology of plastic films and process methods, applied in chemical instruments and methods, coatings, adhesives, etc., to achieve the effect of avoiding wrinkling and wasteful use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

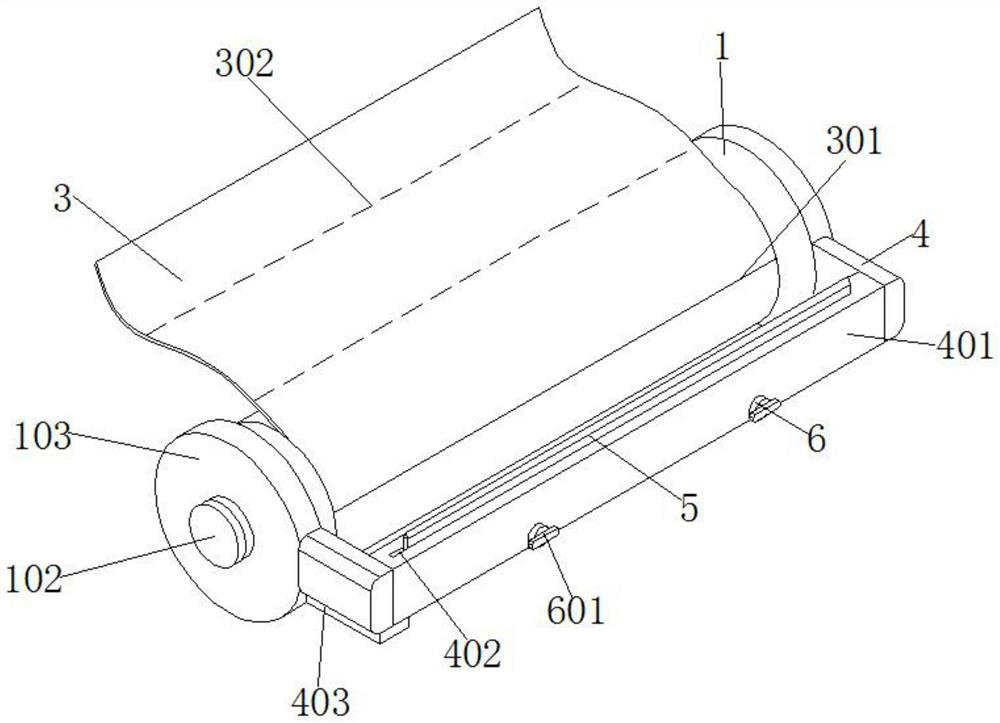

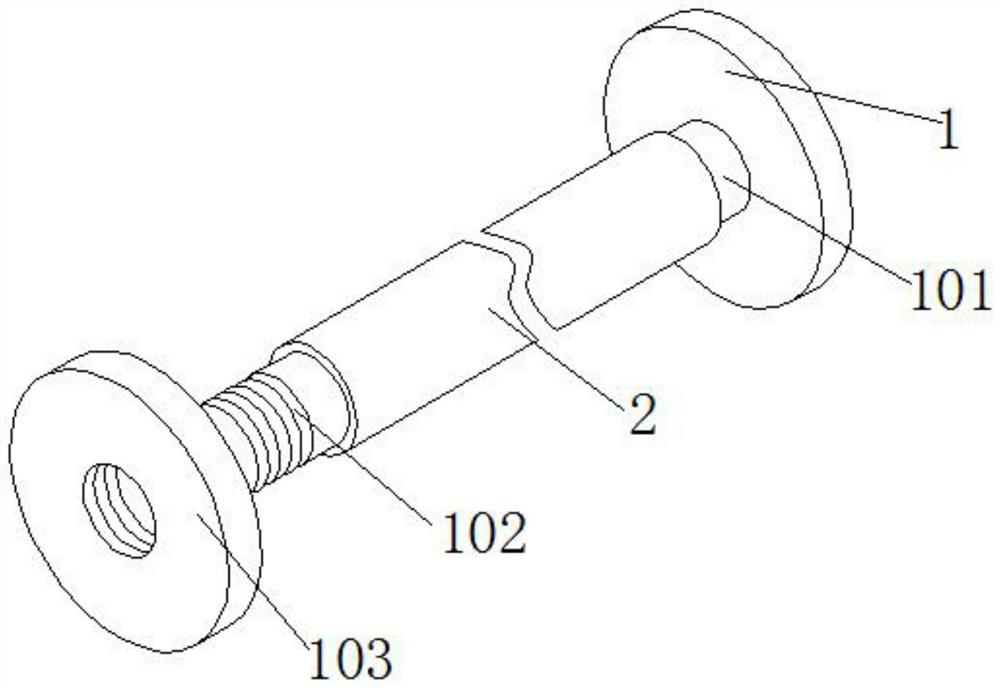

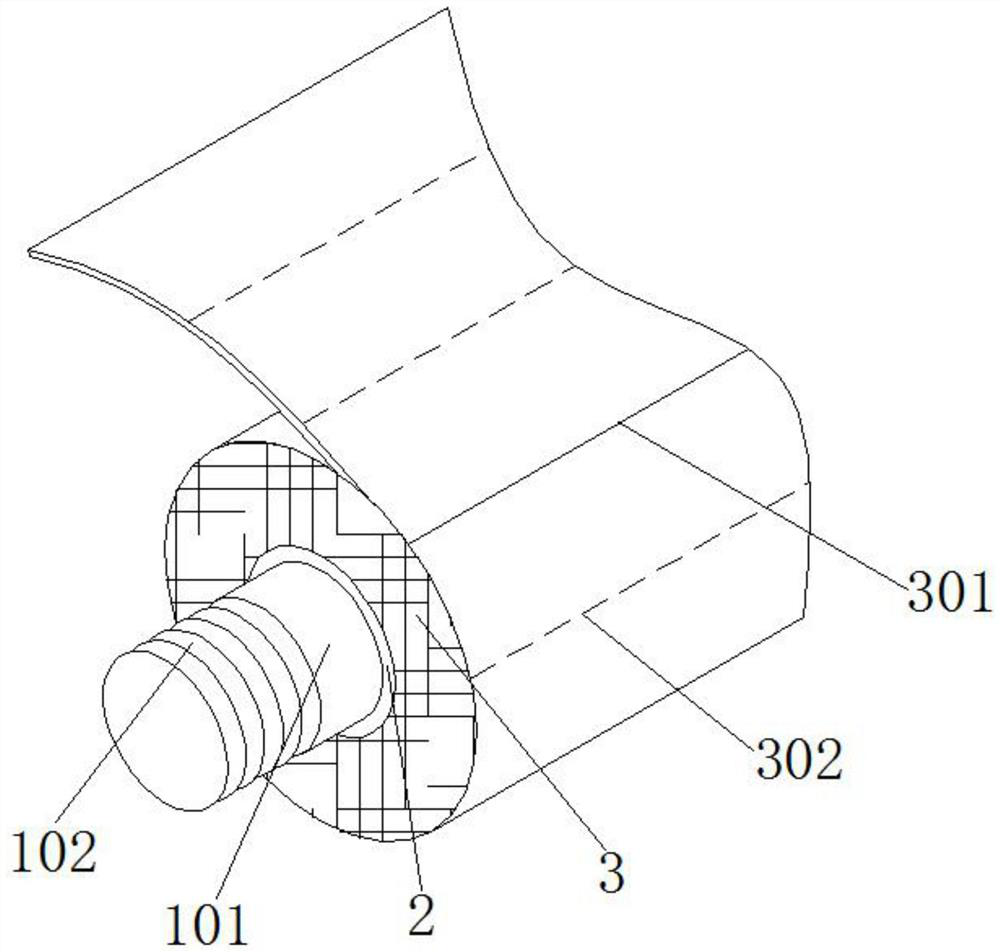

[0039] see Figure 1-Figure 7, a kind of embodiment one that the present invention provides: a kind of PET plastic film post-it note gluing process method with anti-wrinkle effect, comprises baffle plate 1, sleeve 2 and post-it note 3, and the front of baffle plate 1 is installed with The use of the fixed plate 4 and the baffle plate 1 prevents the sleeve 2 from falling on the fixed rod 101 from the side where the baffle plate 1 is located. The fixed plate 4 is used to install the long block 401, and it has a certain length, which is a long block A large space is provided between 401 and the fixed rod 101, so as to avoid the placement of roll-shaped post-it notes from being hindered. A fixed rod 101 is installed on one side of the baffle plate 1, and the fixed rod 101 is used to install the threaded rod 102, and its The diameter is slightly smaller than the diameter of the inner ring of the sleeve 2, which is convenient for inserting the sleeve 2. The outer surface of the fixe...

Embodiment 2

[0049]

[0050]

[0051] 100 parts of synthetic resin composition, 60 parts of additive and 15 parts of microcapsules were introduced into the mixing tank for mixing, and stirred at a speed of 120 rpm to fully integrate the three, and then 0.8 parts of catalyst, 1 part of Plasticizer, 3 parts of anti-aging agent, 50 parts of filler and 12 parts of acrylic self-adhesive, and then fully disperse and stir each raw material composition to obtain a low-viscosity pressure-sensitive adhesive mixture, then collect the mixture, and place 0- After 1 day, functional colloids can be obtained.

Embodiment 3

[0053] A kind of gluing process method for post-it notes of PET plastic film with anti-wrinkle effect, the gluing process steps are as follows:

[0054] (a) Discharging: Put the raw materials into the hopper according to the proportion through the vacuum feeder;

[0055] (b) Mixing of raw materials: start the rotating motor, drive the screw rod to rotate, squeeze each raw material in step (1) into the collection box through the rotation of the screw rod, and start three groups of extraction pumps;

[0056] (c) Mixing and stirring: start three sets of stirring motors, and the running time is 8-10 minutes, then start the vacuum pump, and run for 5 minutes to extract the gas inside the mixing tank;

[0057] (d) Sampling inspection: After the colloids inside the three groups of mixing tanks are formed, open the three groups of mixing tanks in turn, and suck 30g of glue from the surface and bottom of the inner colloids of the three groups of mixing tanks through straws for viscosit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com