Preparation method of stable and light-emitting flexible perovskite quantum dot film and product of stable and light-emitting flexible perovskite quantum dot film

A perovskite and quantum dot technology, applied in luminescent materials, chemical instruments and methods, nano-optics, etc., can solve the problems of photoluminescence quenching, performance degradation of perovskite quantum dots, etc., and meet the requirements of easy operation and equipment Not high, good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

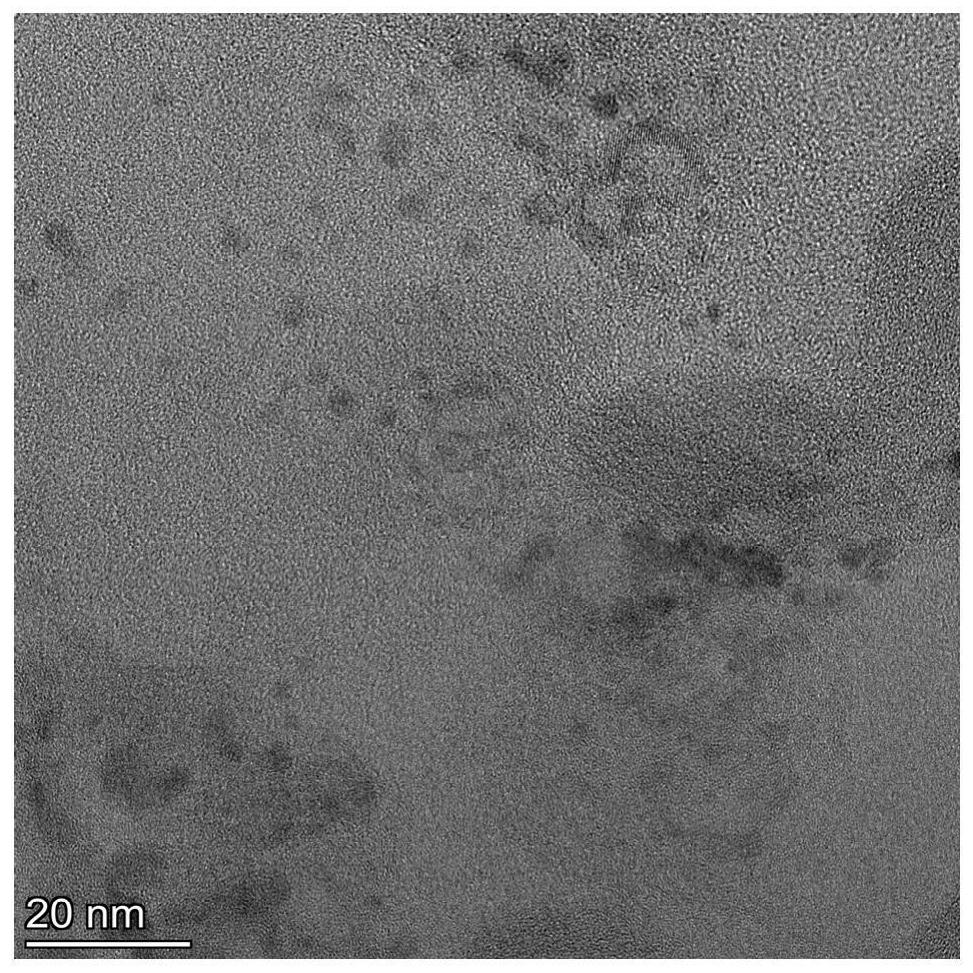

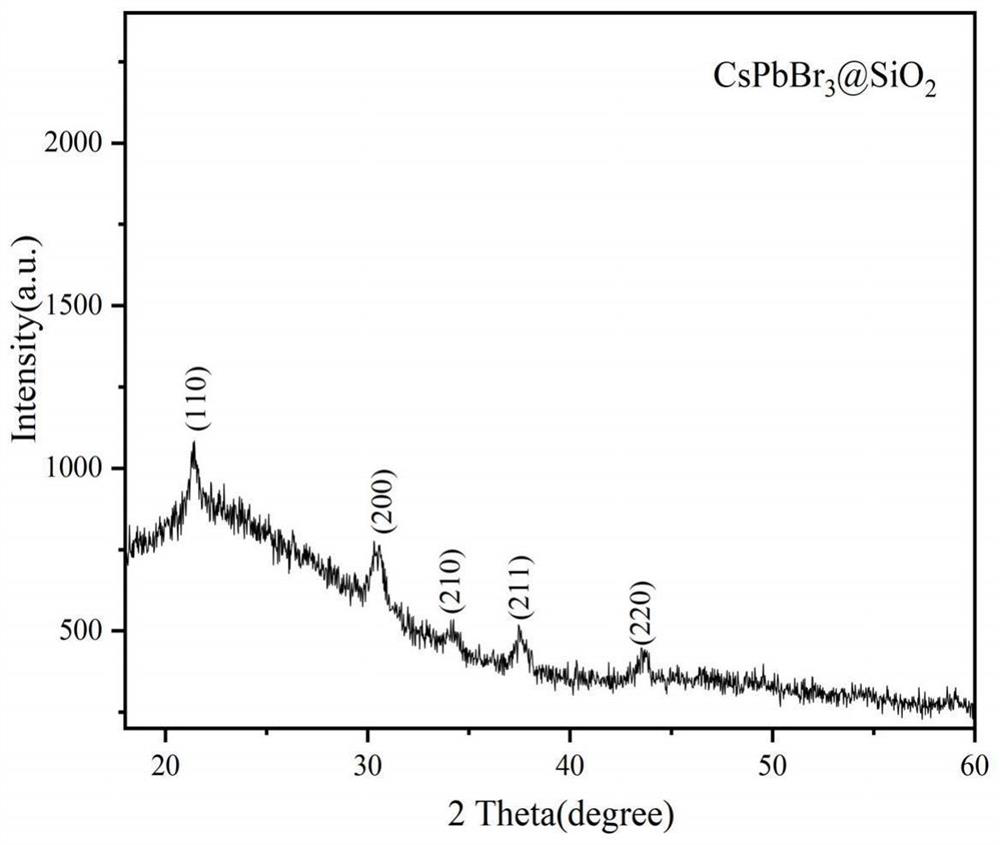

[0034] Preparation of perovskite quantum dot films (CsPbBr 3 @SiO 2 @PDMS), including the following steps:

[0035] (1) CsBr and PbBr 2 Dissolve in 50ml deionized water, stir at 80°C for 30min, make it evenly mixed to form a mixed solution;

[0036] (2) Silicon molecular sieve (MCM-41 molecular sieve, pore size 3.7nm, specific surface area 1000m 2 / g) added to the mixed solution prepared in step (1), stirred for 1 hour, mixed uniformly, and dried at a temperature of 80° C. for 12 hours to obtain the mixture;

[0037] (3) After grinding the mixture in step (2) for 10 minutes in an agate grinding body, in a tube furnace, the temperature is raised to 700°C at a heating rate of 5°C / min, calcined for 30min and then cooled to room temperature to obtain powder;

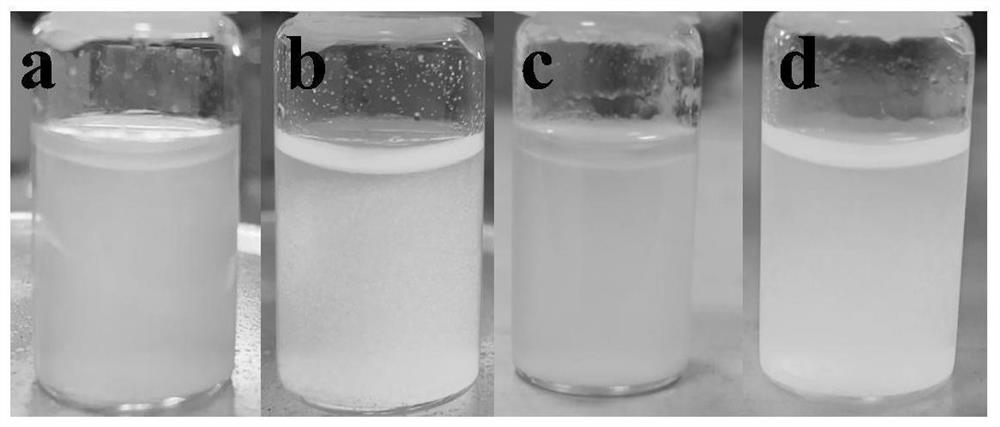

[0038] (4) Grind the powder in step (3) for 10 minutes in agate grinding body, filter and wash with deionized water several times with 0.22um precision filter paper, and then centrifuge to remove the external CsPbBr 3 ...

Embodiment 2

[0041] Preparation of perovskite quantum dot films (CsPbBr 3 @SiO 2 @PDMS), including the following steps:

[0042] (1) CsBr and PbBr 2 Dissolve in 50ml of deionized water, stir at 80°C for 45min, make it evenly mixed to form a mixed solution;

[0043] (2) Silicon molecular sieve (MCM-41 molecular sieve, pore diameter 3.7nm, specific surface area 900m 2 / g) added to the mixed solution prepared in step (1), stirred for 1.2 hours to make it evenly mixed, and dried at a temperature of 60°C for 11 hours to obtain the mixture;

[0044] (3) After grinding the mixture in step (2) for 7 minutes in an agate grinding body, in a tube furnace, the temperature is raised to 700°C at a heating rate of 5°C / min, calcined for 30min and then cooled to room temperature to obtain powder;

[0045] (4) Grind the powder in step (3) for 7 minutes in agate grinding body, filter and wash with deionized water several times with 0.45um precision filter paper, and then centrifuge to remove the externa...

Embodiment 3

[0048] Preparation of perovskite quantum dot films (CsPbBr 3 @SiO 2 @PDMS), including the following steps:

[0049] (1) CsBr and PbBr 2 Dissolve in 50ml deionized water, stir at 80°C for 60min, make it evenly mixed to form a mixed solution;

[0050] (2) Silicon molecular sieve (MCM-41 molecular sieve, pore diameter 3.7nm, specific surface area 950m 2 / g) added to the mixed solution prepared in step (1), stirred for 1.5 hours to make it evenly mixed, and dried at a temperature of 70°C for 10 hours to obtain the mixture;

[0051] (3) After grinding the mixture in step (2) for 5 minutes in an agate grinding body, in a tube furnace, the temperature is raised to 700°C at a heating rate of 5°C / min, calcined for 30min and then cooled to room temperature to obtain powder;

[0052] (4) Grind the powder in step (3) for 5 minutes in an agate grinding body, filter and wash with deionized water several times with 0.33um precision filter paper, and then centrifuge to remove the externa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com