Full-biodegradable insect trapping plate and preparation method thereof

A biodegradable and insect trapping technology, which is applied to devices for capturing or killing insects, animal husbandry, applications, etc., can solve the problems of low degradation efficiency, low degree of automation, and incomplete degradation of insect trapping plates. cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

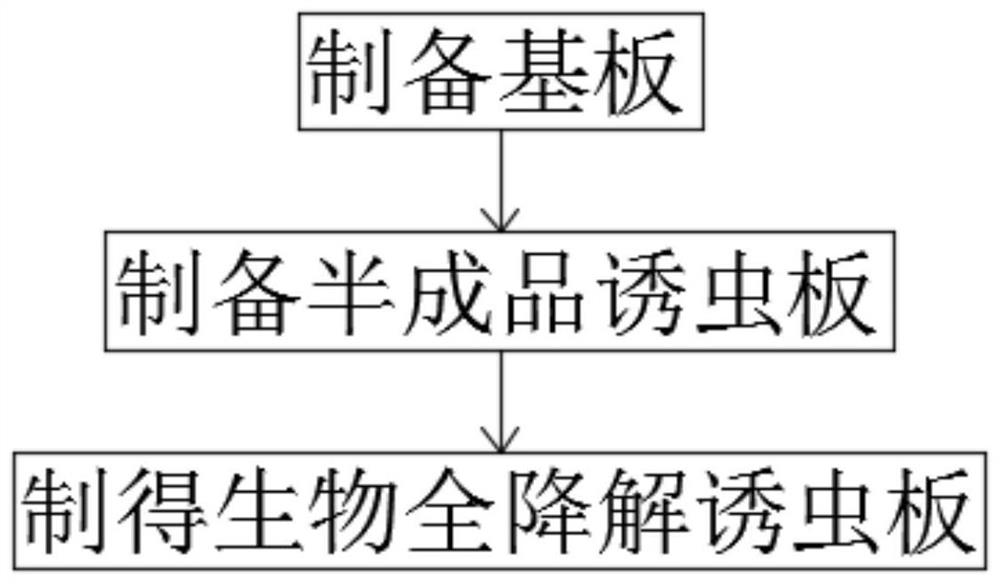

[0035] A method for preparing a biodegradable insect trap, comprising the steps of:

[0036] Step 1: Mix PBAT, PLA, cellulose, biodegradable color masterbatch and additives evenly to obtain the primary mixture, add the primary mixture to the silo of the twin-screw extruder, extrude and granulate to prepare masterbatch, and mix the masterbatch The pellets are added to the sheet extruder, extruded and cut, and the substrate is obtained;

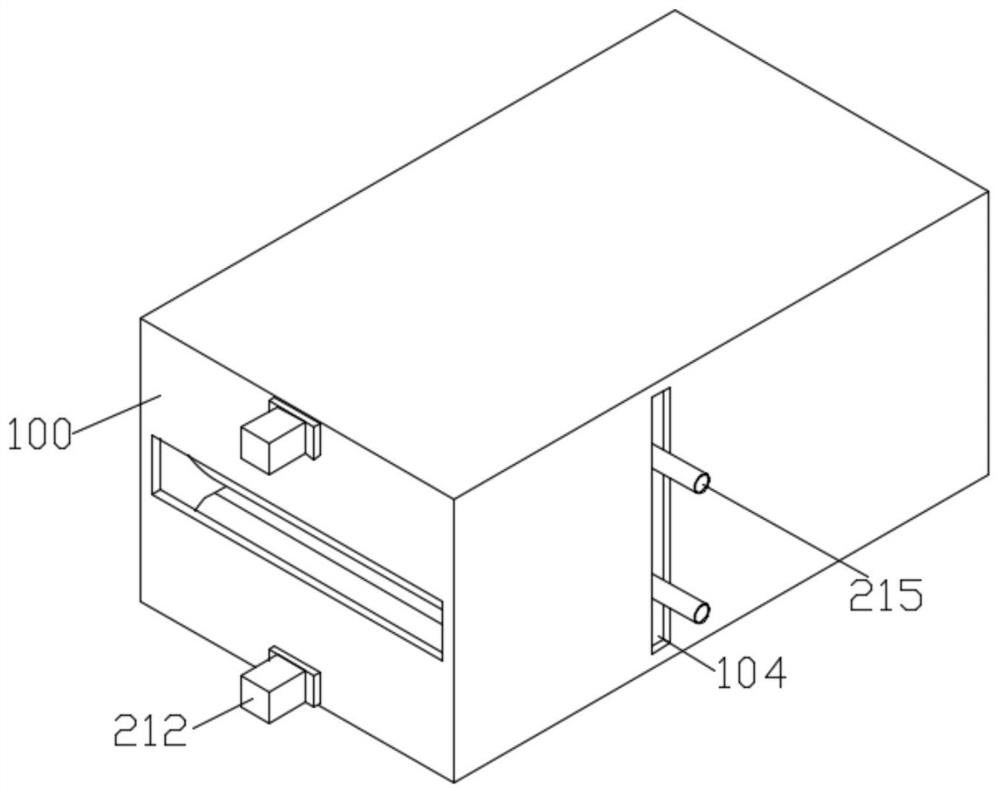

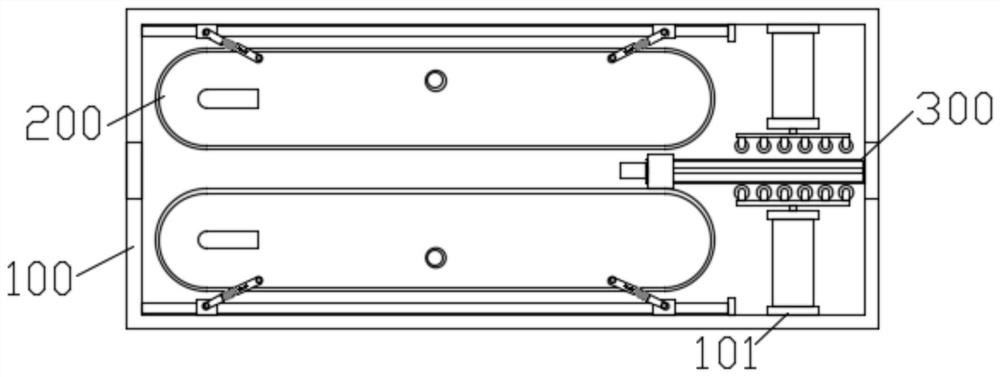

[0037] Step 2: Coat the surface of both sides of the substrate with sticky insect glue, form a sticky shellac layer on both sides of the substrate, and attach a release paper on the sticky shellac layer to obtain a semi-finished insect trap, put the semi-finished insect trap into two Between the two filter belts 205, open the installation motor 212, the output shaft of the installation motor 212 drives the first lead screw 201 to rotate, the first lead screw 201 drives the two adjustment plates 202 to move toward each other, and the two adjustm...

Embodiment 2

[0046] In step 1, the substrate is prepared from the following raw materials in parts by weight: 90 parts of PBAT, 50 parts of PLA, 60 parts of cellulose, 18 parts of biodegradable color masterbatch and 18 parts of additives.

[0047] The auxiliary agent is prepared from the following raw materials in parts by weight: 5 parts of crosslinking agent, 10 parts of plasticizer and 5 parts of lubricant.

[0048] The crosslinking agent is benzoyl peroxide; the plasticizer is epoxy soybean oil; the lubricant is ethylene bis stearamide.

[0049] Cellulose is bagasse extract.

[0050] In step 1, the extrusion temperature of the silo of the twin-screw extruder is 265° C., the head temperature is 265° C., the rotation speed is 650 rpm, and the extrusion temperature of the sheet extruder is 250° C.

[0051] Insect attractants include plant-derived terpenoids, plant-derived green leafy compounds, and liquid paraffin.

[0052] The 25-day degradation rate of the fully biodegradable insect t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com