Drying device for high-content carbon black masterbatch

A carbon black masterbatch and drying device technology, applied in the direction of drying gas arrangement, drying chamber/container, drying solid materials, etc., can solve the problems of affecting product quality, processing quality reduction, unfavorable storage of carbon black masterbatch, etc., to improve material quality Color performance, effects that improve coloring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

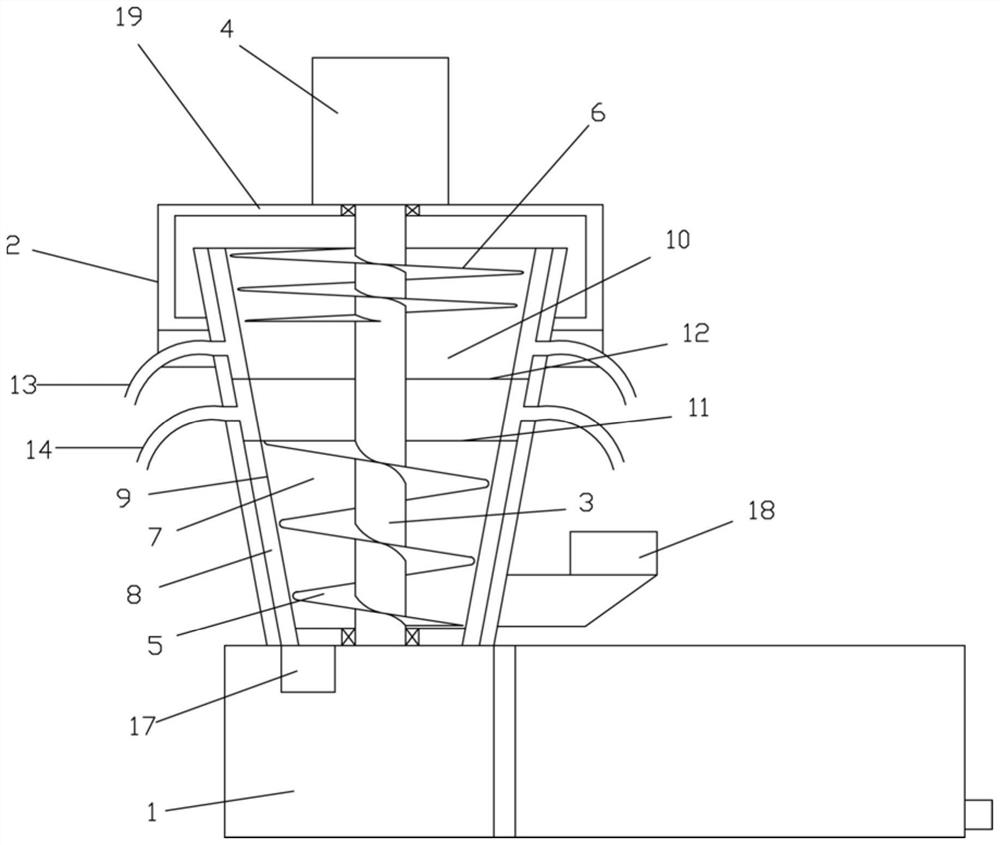

[0033] In order to understand the technical features, objects and effects of the present invention, specific embodiments of the present invention will be described with reference to the drawings.

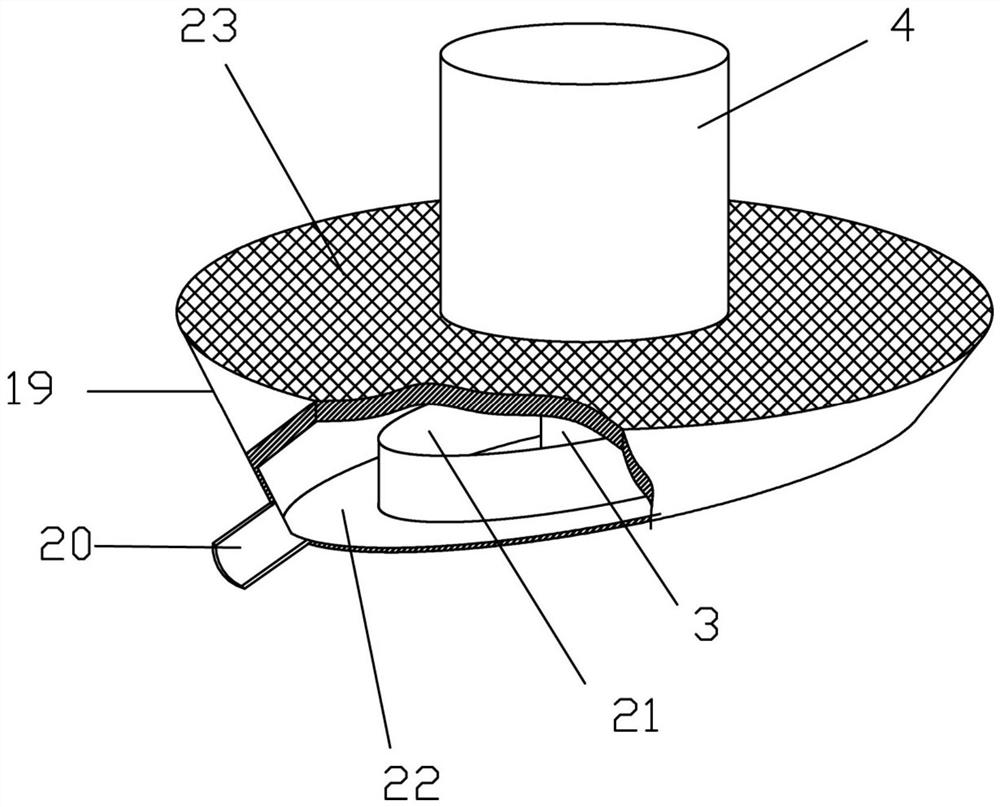

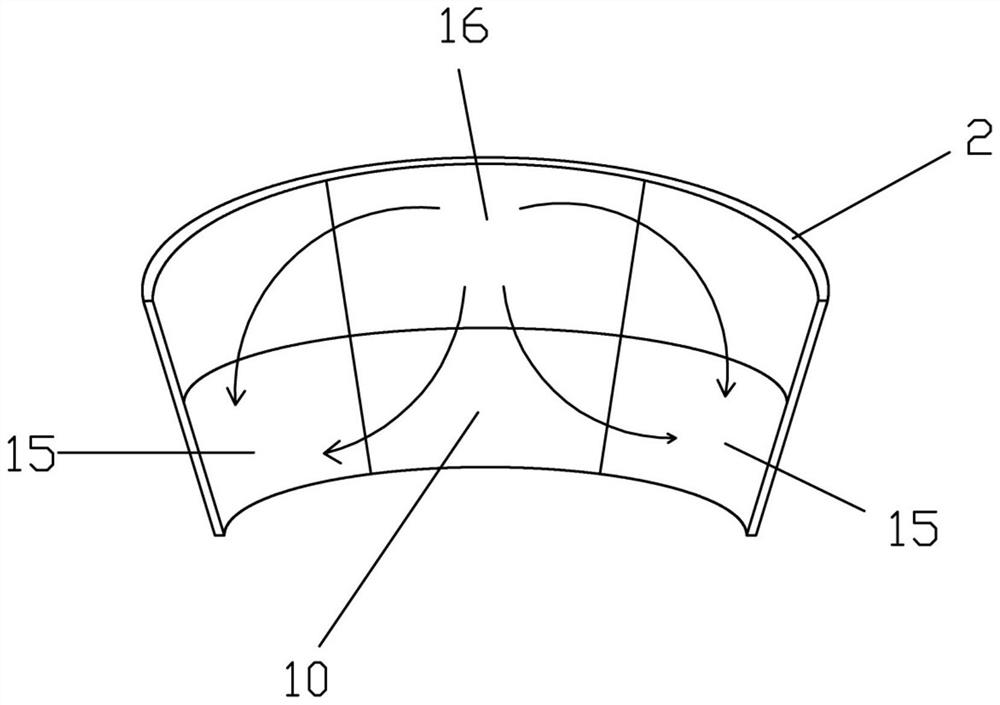

[0034] In a preferred embodiment of the present invention, please refer to figure 1 with figure 2, The drying apparatus of the present invention, a high content of carbon black masterbatch comprises a water tank 1, a centrifugal mechanism 2 and the dehydration chamber, the water tank 1 is a top opening structure, which is mounted on top of the dewatering chamber 2, the water tank 1 2 extends to the outside of the dehydration chamber is a drain groove portion 1; the dewatering chamber 2 equipped with an annular separating screen 9, the separating screen 9 preferably a ring, the separating screen 9 inner centrifugal chamber 7, the centrifugal mechanism for centrifugal movement, that the masterbatch adhesion and water to be brought up; separating screen 9 of the outer discharge chamber 8 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com