Anode catalyst layer slurry and preparation method thereof

A catalytic layer and anode technology, applied to battery electrodes, structural parts, electrical components, etc., can solve unsolvable problems, achieve low battery internal resistance, prevent water accumulation, and improve mass transfer capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention also provides a method for preparing an anode catalyst layer slurry comprising:

[0033]a, perfluorosulfonic acid resin was added to the solution and diluted with a solvent, the concentration preferably perfluorosulfonic acid resin solution is 20 to 40%, stirring speed is preferably 100-400r / min, stirring time of 30-60 min, perfluorosulfonic acid resin solids content of the diluted solution obtained is 2-20wt%;

[0034] b, / C catalyst was added to the Pt water, mixing, dilution perfluorosulfonic acid resin obtained in step a was then added and an emulsion of polytetrafluoroethylene, a ball mill, the speed is preferably 100-500r / min, the milling time is 1 4h, to obtain a catalyst slurry.

[0035] The method for preparing the anode catalyst layer slurry to an embodiment of the present invention, addition of a perfluorosulfonic acid resin EW of 650-750g / mol, since the resin is capable of providing more sulfonate, so that the present invention is pr...

Embodiment 1

[0041] First, the anode catalyst layer slurry was prepared

[0042] (1) resin dilution preparation: Weigh 2g perfluorosulfonic acid resin solution (resin content is 25wt%), EW perfluorosulfonic acid resin is from 680g / mol, and then diluted with ethanol added, the solid content of the resin solution was diluted 10wt%, stirred with a magnetic stirrer 30min, the rotational speed of 300rpm, until the resin solution is clear and transparent without bubbles;

[0043] After weighing Pt / C (Pt content of 50% by mass) 1g of catalyst into a ball mill jar, deionized water was added dropwise 5g catalyst sufficiently wetted, mixed on an analytical balance: (2) anode catalyst layer slurry was prepared , were added in step (1) obtained in the perfluorosulfonic acid resin solution was diluted PTFE dispersion and 1.25g (60% PTFE), to control the quality of the carbon support resin and catalyst ratio I / C = 1.0, ethanol was added and finally, control catalyst layer slurry solids content of 8wt%...

Embodiment 2

[0050] The same manner as Example 1, except that the anode catalyst layer slurry prepared in step (2), the resin and catalyst mass ratio of carbon support I / C = 0.9.

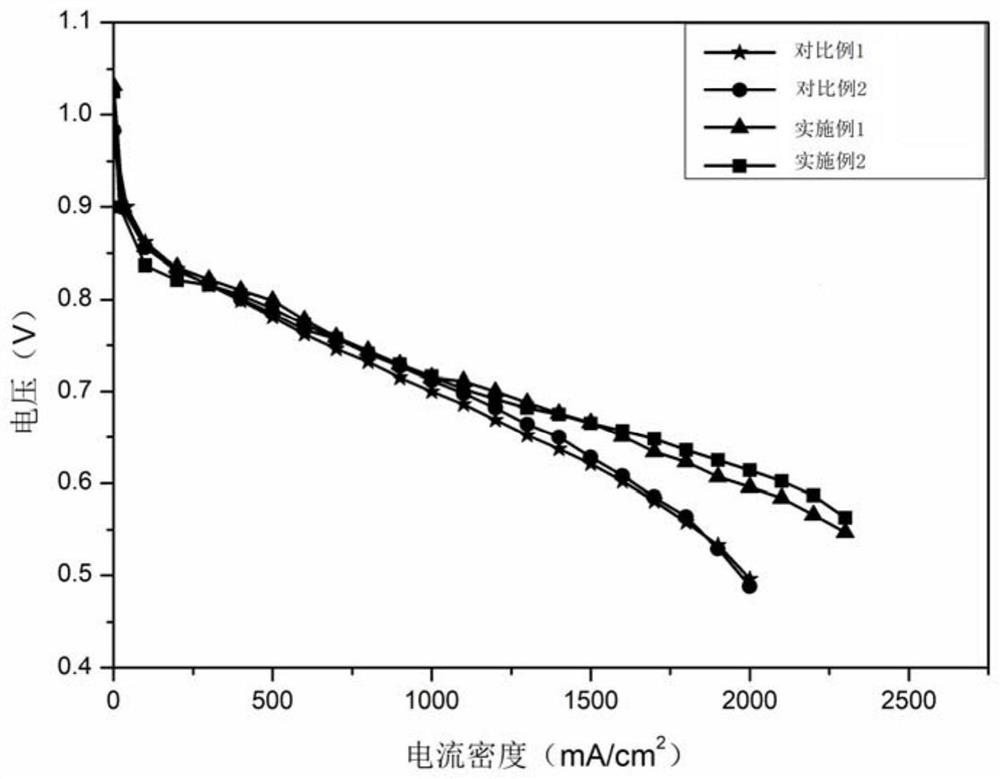

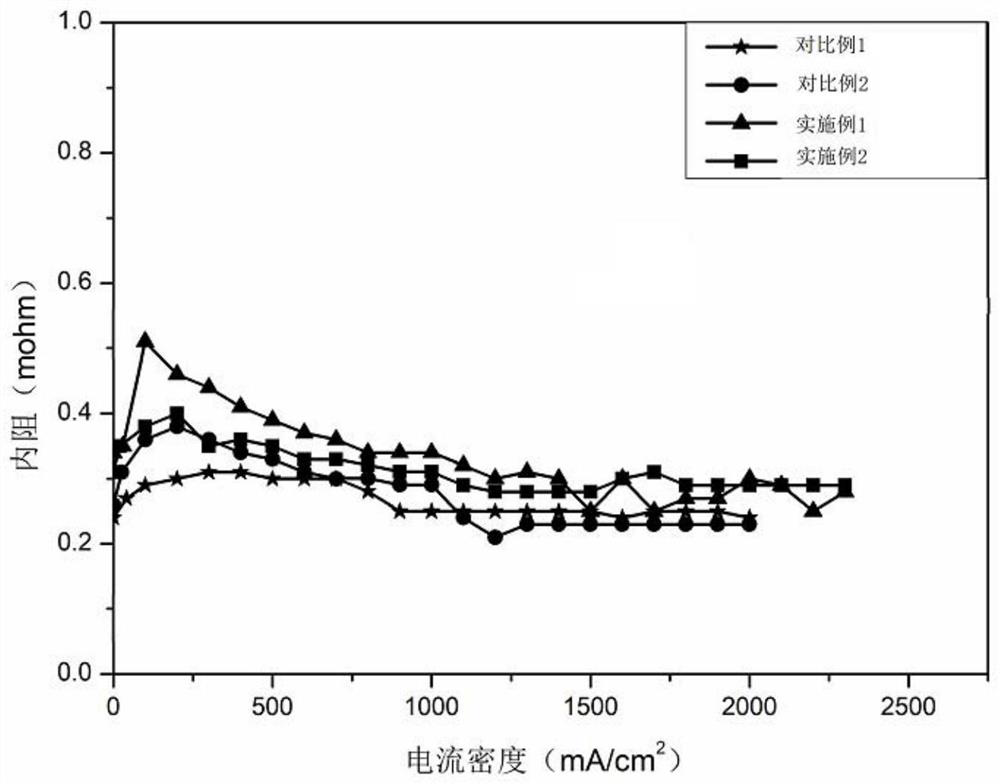

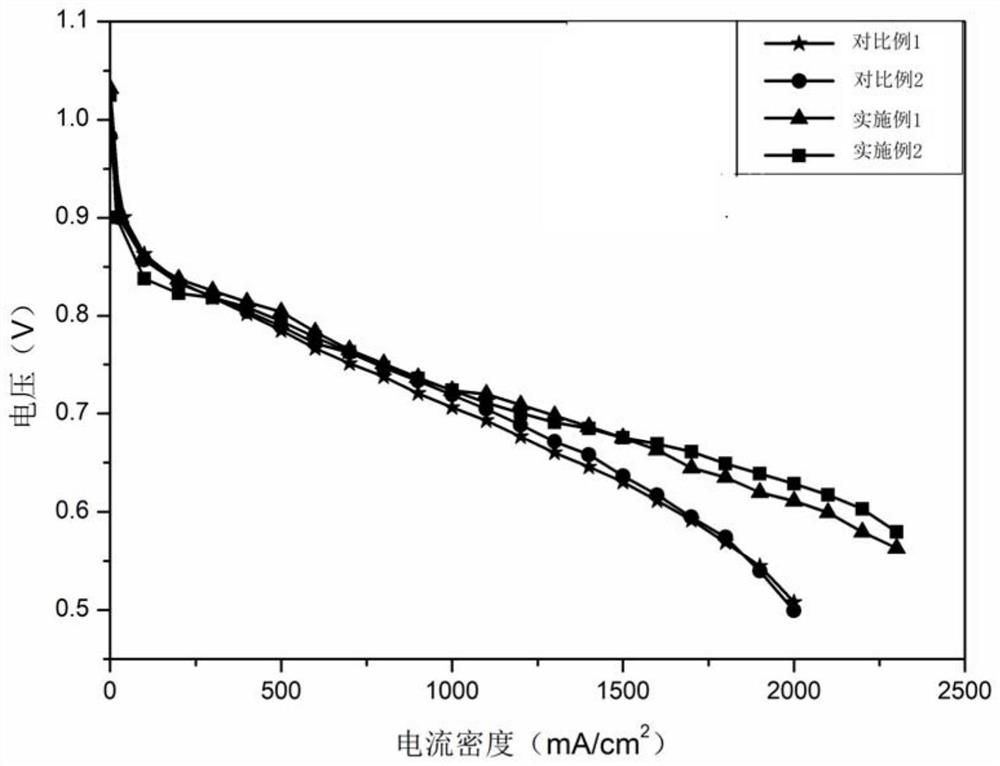

[0051] Performance Test Example 2 to obtain the membrane electrode embodiment of results are Figure 1-3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com