Centrifugal vacuum defoaming equipment for online continuous treatment

A vacuum defoaming and centrifugal technology, which is applied in the direction of liquid degassing, separation method, foam dispersion/prevention, etc., can solve the problems of incomplete slurry treatment, large slurry bubble content, difficult maintenance and repair, etc., and achieve the design High efficiency, reasonable mechanism of action, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

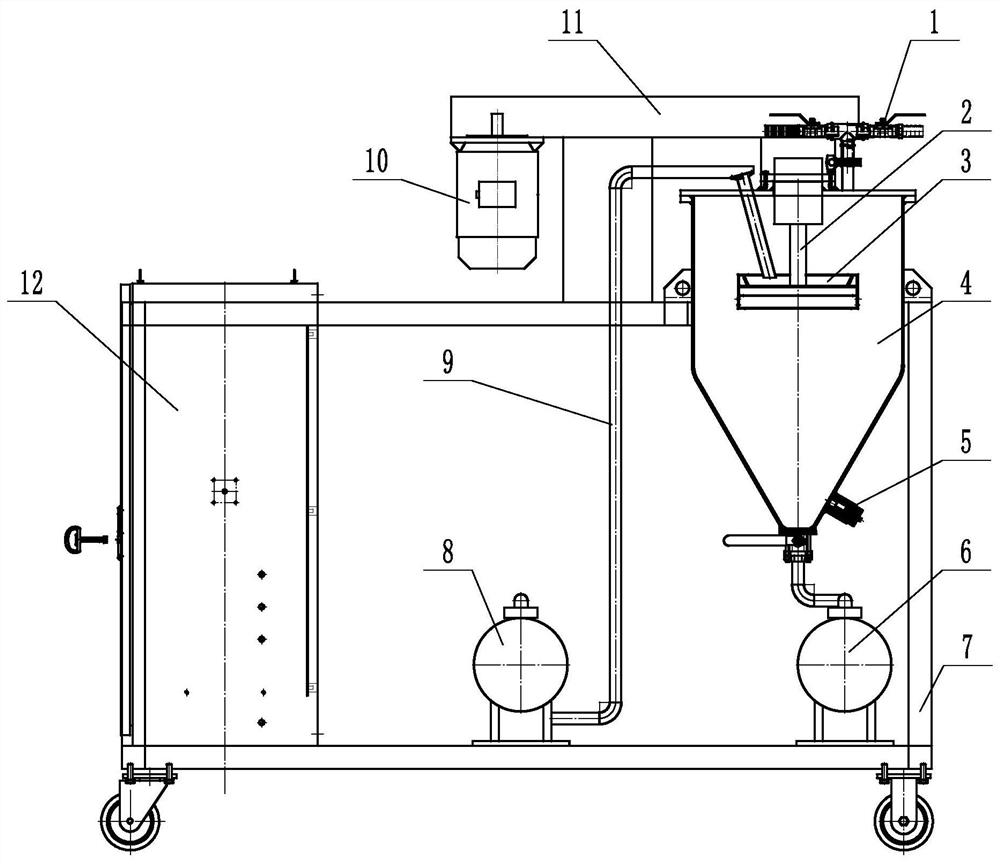

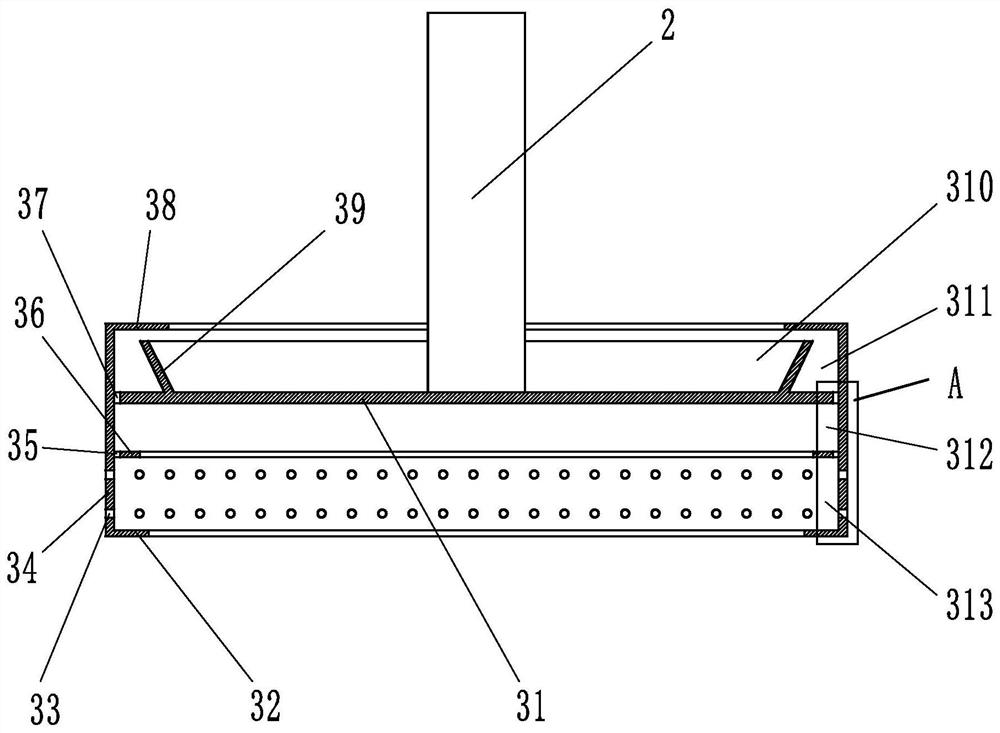

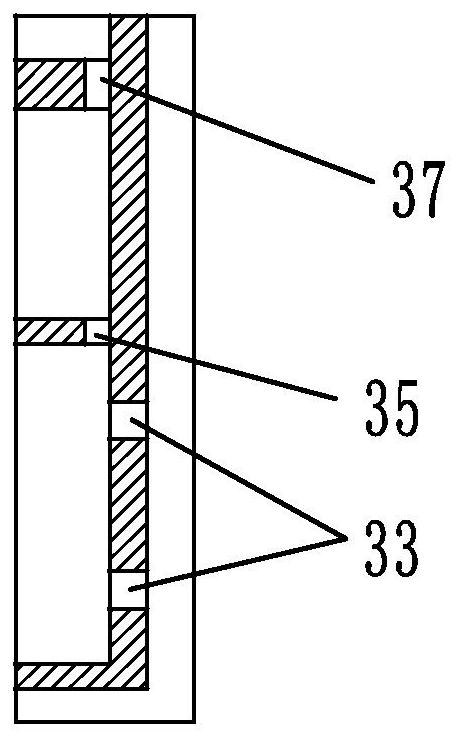

[0027] Embodiment: a kind of centrifugal vacuum degassing equipment of online continuous processing, such as Figure 1-Figure 3 Shown, comprise frame 7, feed pump 8, discharge pump 6, defoaming disc 3, rotating shaft 2, power unit 10 and the tank body 4 that is installed on the frame, transmission system 11, described feed pump 8 The defoaming disc 3 is communicated with the defoaming disc 3 through the feeding pipeline 9, the defoaming disc 3 is connected with the rotating shaft 2, and the rotating shaft is connected with the power device through the transmission system, and the tank body 4 is a closed container, and a vacuum port 1 is arranged on it , by vacuuming the inside of the tank to be in a negative pressure or vacuum state, to achieve the purpose of vacuum defoaming. There is a discharge port at the lower end of the tank body, and the discharge port communicates with the discharge pump 6 . The bottom of the tank body is provided with a liquid level gauge 5, and insp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com