A method and system for controlling the accuracy of ink droplet drop point for inkjet printing

A precision control, inkjet printing technology, applied in printing and other directions, can solve the problems of insignificant improvement of ink droplet accuracy, easy introduction of other errors, no light, etc., to achieve easy ink droplet accuracy control and compensation. The effect is obvious, the compensation effect is stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

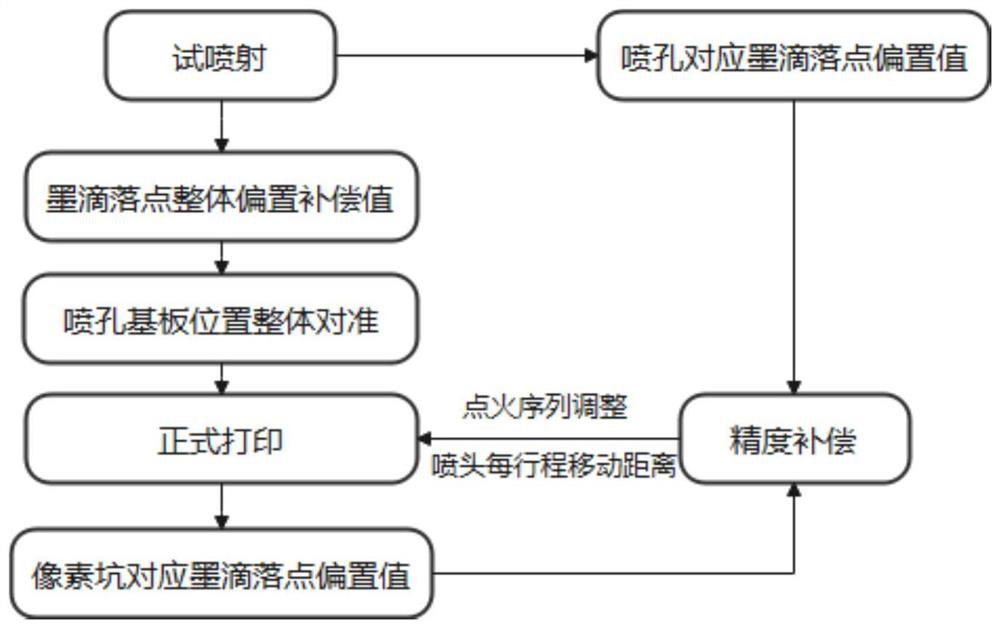

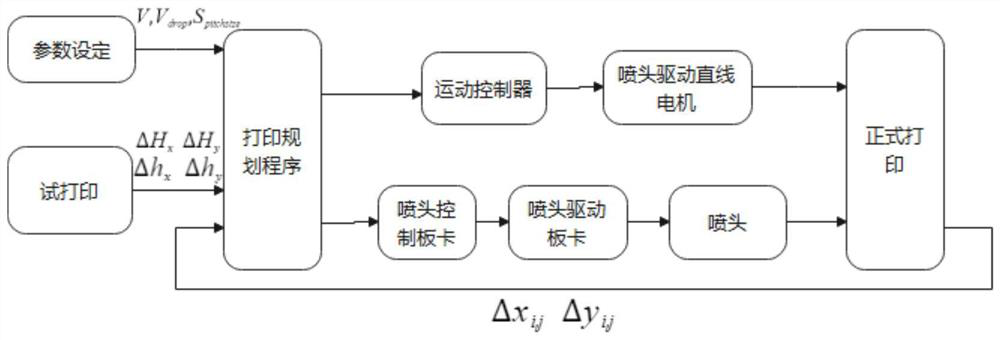

[0056] figure 1 It is a flow chart of the method for controlling the accuracy of ink droplets for inkjet printing according to the present invention, figure 2 As a preferred embodiment of the method, the control method includes the following steps:

[0057] Step 1: Carry out the trial printing process.

[0058] Specifically, move the nozzle to the trial printing area, and spray all nozzle holes at a predetermined position once; by detecting the drop point position and the state of the ink droplet corresponding to each nozzle hole, the offset value of the drop point corresponding to each nozzle hole is calculated. , and calculate the overall offset compensation value of the ink droplet landing point.

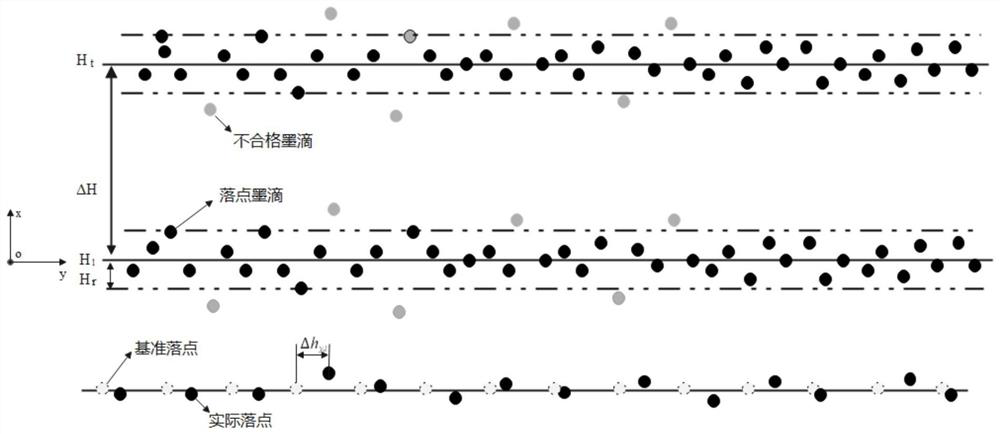

[0059] see image 3 , in the trial printing stage, multiple measurements are required to obtain the corresponding drop point position h of each nozzle hole. q , calculate the overall offset compensation value ΔH of the ink droplet landing point in the moving direction of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com