A kind of electronic paper pasting equipment

A laminating equipment and electronic paper technology, applied in identification devices, thin material processing, instruments, etc., can solve the problems of disrupting the normal operation of the production line, high adhesion force between the substrate and the roller, and low production efficiency, so as to shorten the production cycle , reduce the error rate and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

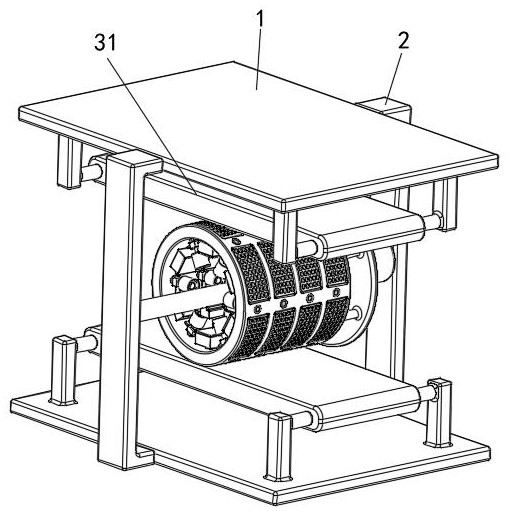

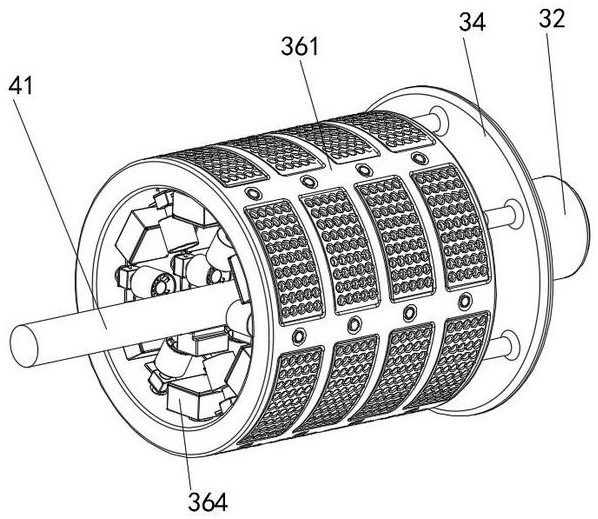

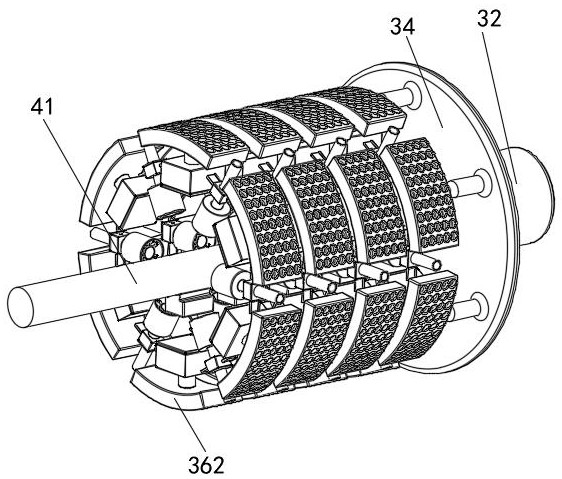

[0040] see Figure 1-6 , a kind of electronic paper pasting equipment, comprising a fixed plate 1, a fixed frame 2, a bonding device 3, a magnetic device 4 and a suction device 5, the left and right sides of the fixed plate 1 are fixedly connected with the fixed frame 2, and the fixed plate 1 is about There are two symmetrically arranged upper and lower sides of the fixed frame 2, a fitting device 3 is arranged between the two fixing plates 1, a magnetic device 4 is arranged at the axial inner center of the fitting device 3, and a suction device 5 is fixedly installed on the fitting on device 3;

[0041]Laminating device 3 comprises conveyer belt mechanism 31, first motor 32, rotating shaft 33, rotating disk 34, branch bar 35 and roller device 36, and fixed plate 1 is connected with conveyer belt mechanism 31 by being fixedly connected with connecting block and rotatably connected, and the left side of fixed mount 2 The side is fixedly connected with a first motor 32, the lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com