Solar self-sufficient fresh water and sea salt co-production system and operation method thereof

A solar energy, self-sufficient technology, applied in the field of solar energy and seawater desalination to extract salt, can solve the problems of waste of energy, high cost, single target, etc., and achieve the effect of reducing system operating cost, improving operating efficiency, and high economic efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

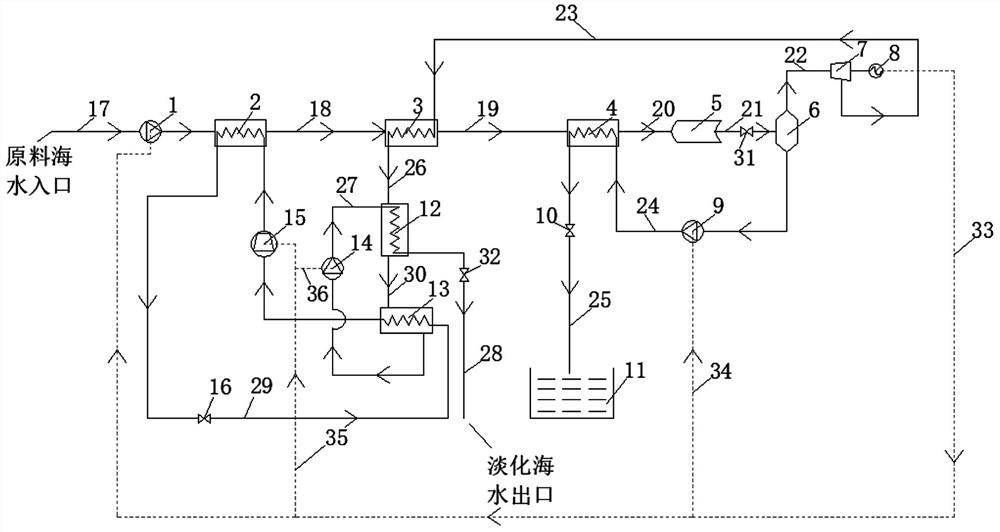

[0026] see figure 1, a self-supporting freshwater sea-salt cogeneration system utilizing solar energy, which includes a first pressurized water pump 1, the first pressurized water pump 1 is connected to the first casing heat exchanger 2, and the inlet of the first pressurized water pump 1 is connected to the The raw seawater is connected by a pipeline 17; the right port of the first sleeve heat exchanger 2 is connected to the left port of the second sleeve heat exchanger 3 through the first pipeline 18; the second sleeve heat exchanger 3 The right port is connected to the left port of the third sleeve heat exchanger 4 through the second pipeline 19; the right port of the third sleeve heat exchanger 4 is connected to the medium-high temperature concentrated solar energy through the third pipeline 20 Heater 5, the medium-high temperature focused solar heater 5 is provided with a temperature sensor and a pressure sensor, which can monitor the internal temperature and pressure of ...

Embodiment 2

[0033] An operating method of a self-sufficient freshwater sea-salt cogeneration system utilizing solar energy:

[0034] When the system starts to operate, the method is that both the second shut-off valve 31 and the third shut-off valve 32 are in the closed state, the raw seawater is connected to the raw seawater inlet 17 and enters the first casing for heat exchange when the first pressurized water pump 1 is running Heat exchange between the refrigerant in the heat exchanger 2 and the inner casing pipeline, the refrigerant condenses and releases heat in the inner casing of the first sleeve heat exchanger 2, and the heated raw seawater enters the second casing through the first pipeline 18 The exhaust steam in the heat exchanger 3 and the inner casing pipe is exchanged again, and the raw seawater after the second temperature rise enters the third casing heat exchanger 4 and the high-temperature liquid state in the inner casing through the second pipeline 19 After heat exchang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com