Process for improving methane yield of anaerobic digestion of excess sludge through pretreatment of papermaking white mud

A technology for papermaking white mud and excess sludge, which is applied in sludge treatment, biological sludge treatment, water/sludge/sewage treatment, etc., can solve the problems of slow degradation rate and long reaction period, and achieves simple equipment and reduced Investment and operating expenses, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

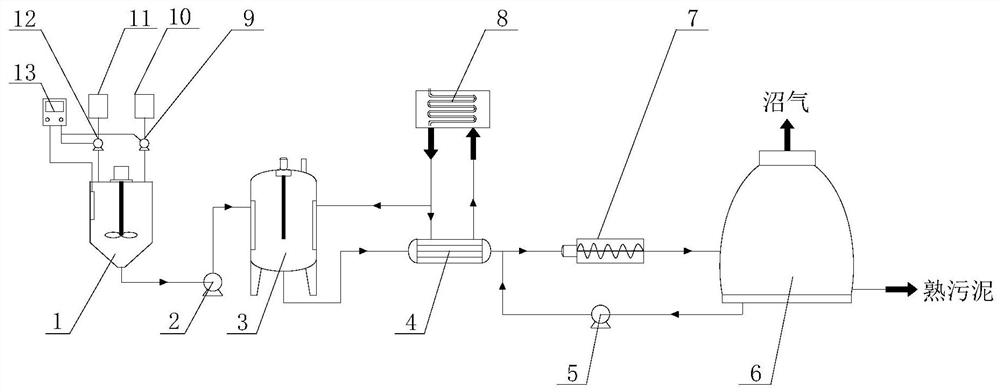

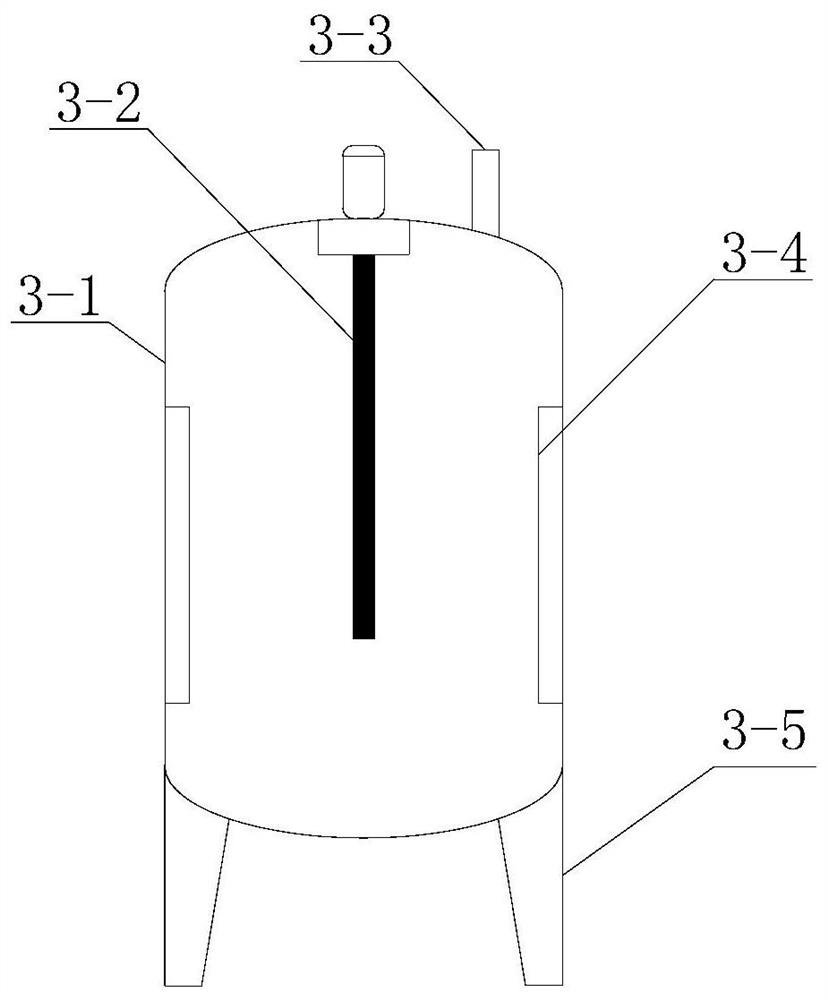

[0029] exist figure 1 Among them, a kind of paper-making white mud pretreatment that the present invention relates to improves the technology that excess sludge anaerobic digestion methane yield is made up of the following steps:

[0030] S1. Concentrating the remaining sludge to obtain concentrated sludge with a water content of 93% to 94%;

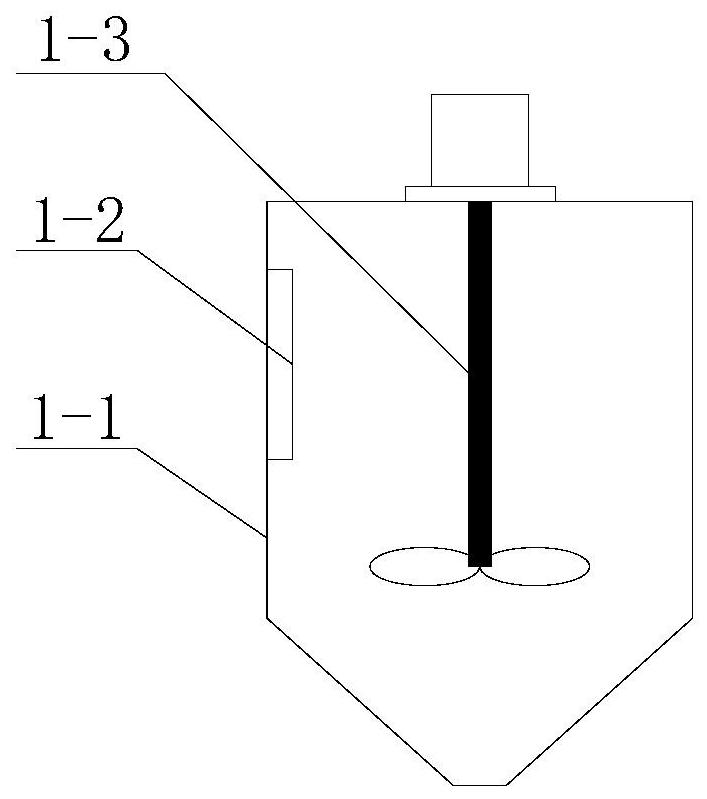

[0031] S2. Mix the concentrated sludge and papermaking white mud in the alkaline hydrolysis tank 1, and the papermaking white mud and the concentrated sludge discharged from the sludge concentration tank are in the ratio of 1 to 2kg / m3, that is, the input of papermaking white mud in every m3 of sludge The amount is 1-2kg. Since the water content of the concentrated sludge is still high, the water content after concentration by different equipment is different. According to the experimental results, in order to obtain a reliable effect of alkali hydrolysis of the sludge, it is more effective to add 1 to 2 kg of papermaking white mud per ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com