Process for laser cladding of nickel-based alloy powder on copper alloy primary mold glass mold

A laser cladding and glass mold technology, applied in metal material coating process, coating and other directions, can solve the problems of uncontrollable welding layer width, low qualification rate, large amount of powder, etc., to ensure product quality consistency and Stability, ensuring consistency and yield, reducing scrap and rework

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Taking laser cladding of a copper alloy beer bottle mold (primary mold) as an example, a specific implementation method of laser cladding nickel-based alloy powder process for a copper alloy primary mold glass mold is described. The steps are as follows:

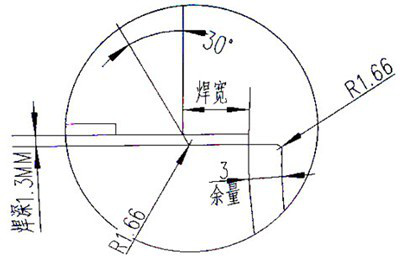

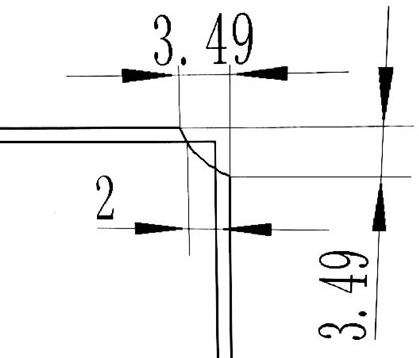

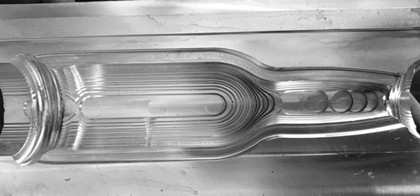

[0030] A) Cavity pre-processing, turning and milling on the joint surface of the mold and the upper and lower interface models, milling out the welding groove, controlling the size of the groove, and obtaining the workpiece to be laser cladding. In this example, the seam line, the upper and lower interface weld grooves and their dimensions are as follows: figure 1 , 2 shown. The initial mold workpiece after grooving is as follows: image 3 shown.

[0031] B) Pre-treatment of laser cladding: Clean the welding groove of the workpiece to be laser cladding, remove burrs and oil stains.

[0032] C) Import the 3D model of the glass mold into the Robotmaster offline programming software, model and generate a cladding tra...

Embodiment 2

[0036] Taking the laser cladding of the die as an example, a specific implementation method of the laser cladding nickel-based alloy powder process for the glass mold of the copper alloy primary mold is described, and the steps are as follows:

[0037] A) Cavity processing: the same requirements as in Example 1, the die is processed, and the slots obtained are as follows Figure 5 shown.

[0038] B) Pre-treatment of laser cladding: same as Example 1.

[0039] C) Import the 3D model of the glass mold into the Robotmaster offline programming software, model and generate a cladding trajectory program, and then download it to the robot system for teaching programming.

[0040]D), Laser cladding: The equipment used is the same as the example, the process parameters are: the focal spot is φ3.5mm, the working distance of the powder feeding nozzle of the cladding head is 21mm, the laser output power is 2600W, and the powder feeding amount is 25g / min. The protective gas used is: argo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com