A load optimization method and system for segmental correction of structural parts processing deformation

A technology of processing deformation and optimization method, applied in design optimization/simulation, instrument, geometric CAD, etc., can solve problems such as incomplete correction, rough correction method, over-correction of structural parts, etc., to prevent the reduction of surface quality and calculate the results The effect of high accuracy and satisfactory calibration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

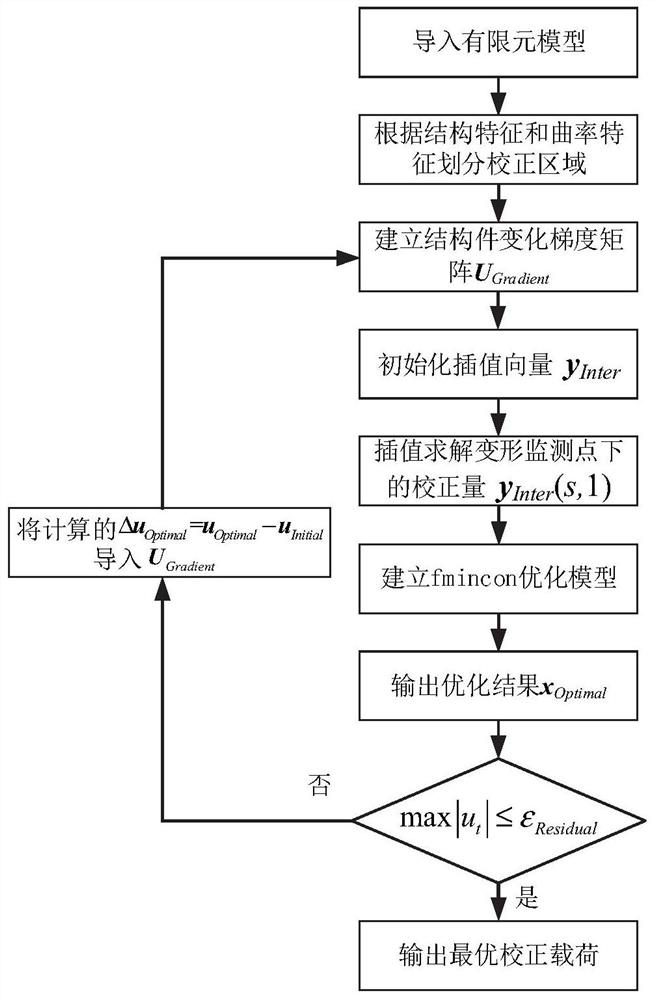

[0039] In the technical solutions disclosed in one or more embodiments, such as figure 1 As shown in the figure, an optimization method for segmental correction load of structural parts processing deformation includes the following steps:

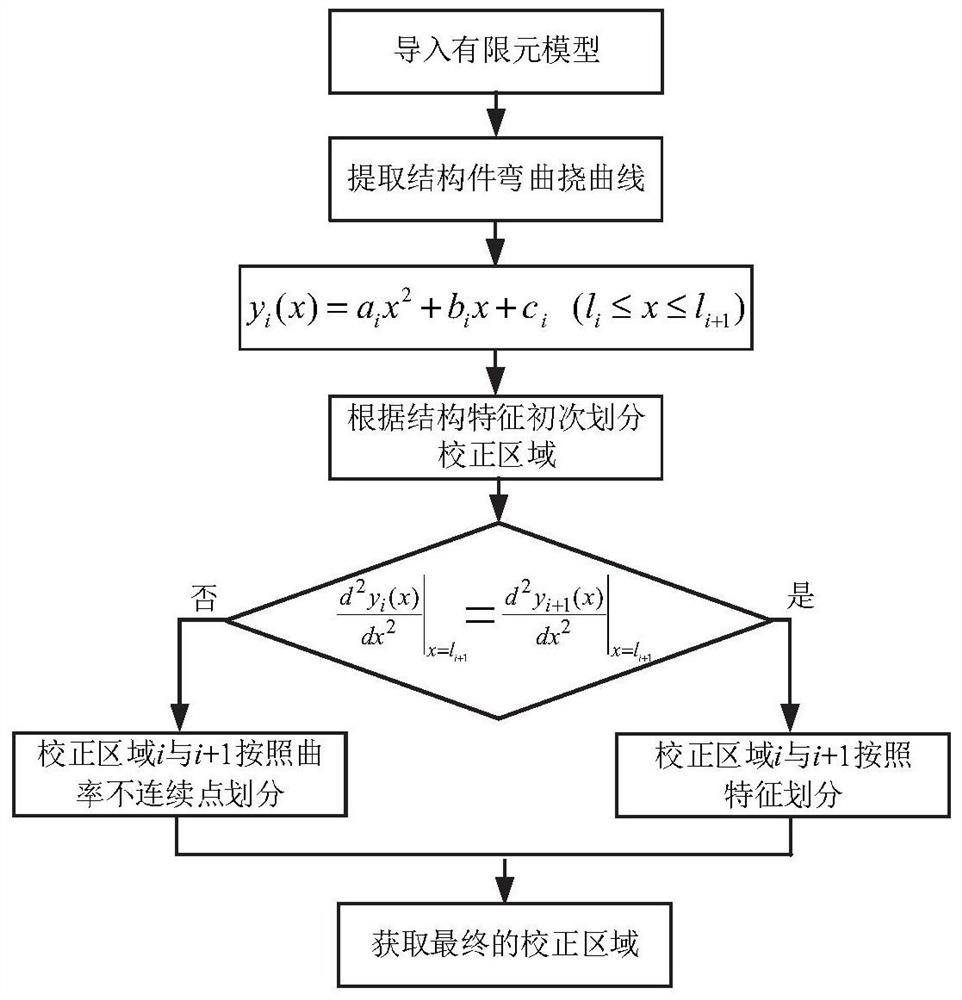

[0040] Step 1) dividing the correction area: according to the structural features of the part to be corrected and the curvature characteristics of the machining deformation deflection line, the machining deformation area is segmented to obtain a plurality of correction areas;

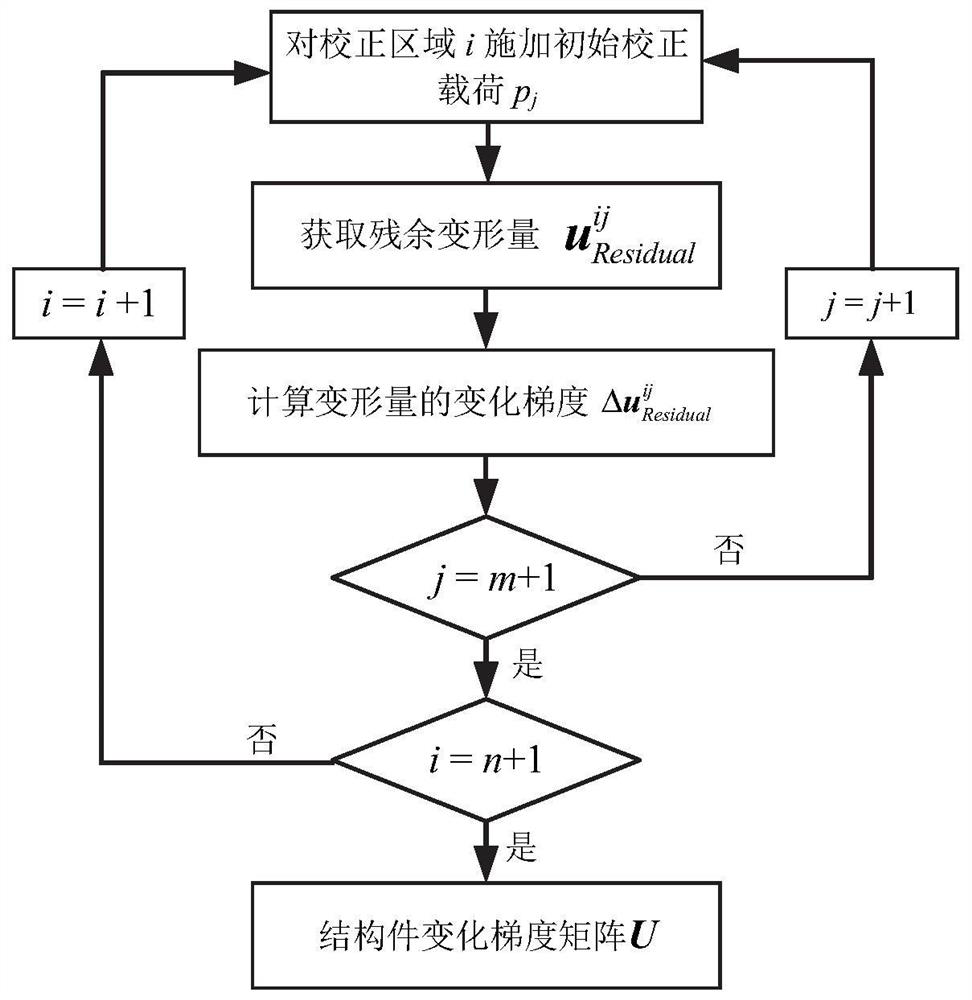

[0041] Step 2) obtaining initial calibration and optimization data: obtaining the initial calibration and optimization data of each calibration area under the action of the initial calibration load;

[0042] Step 3) Solving by the constructed correction load optimization model: According to the obtained initial correction load optimization data, for the constructed correction load optimization model, a nonlinear minimum optimization function is used to solve the prob...

Embodiment 2

[0099] Based on Embodiment 1, this embodiment provides a structural part machining deformation correction load optimization system, including a correction area division module: configured to The deformed area is segmented to obtain multiple correction areas;

[0100] Initial calibration and optimization data acquisition module: configured to acquire the initial calibration and optimization data of each calibration area under the action of the initial calibration load;

[0101] Solving module: According to the obtained initial calibration optimization data, for the constructed calibration load optimization model, the nonlinear minimum optimization function is used to solve the problem, and the optimal calibration load value of each calibration area is obtained;

[0102] The corrective load optimization model is constructed with the goal of minimizing residual deformation.

Embodiment 3

[0104] This embodiment provides an electronic device, including a memory, a processor, and computer instructions stored in the memory and executed on the processor. When the computer instructions are executed by the processor, the steps described in the method of Embodiment 1 are completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com