Method for measuring residual deformation of micro-nano metallic interconnect

A technology of metal interconnection and residual deformation, which is applied in the direction of measuring devices, instruments, and optical devices, etc., can solve the problems that it is difficult to be suitable for metal interconnection and micro-nano metal interconnection, and achieve simple operation, The effect of high measurement accuracy and accurate spatial positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

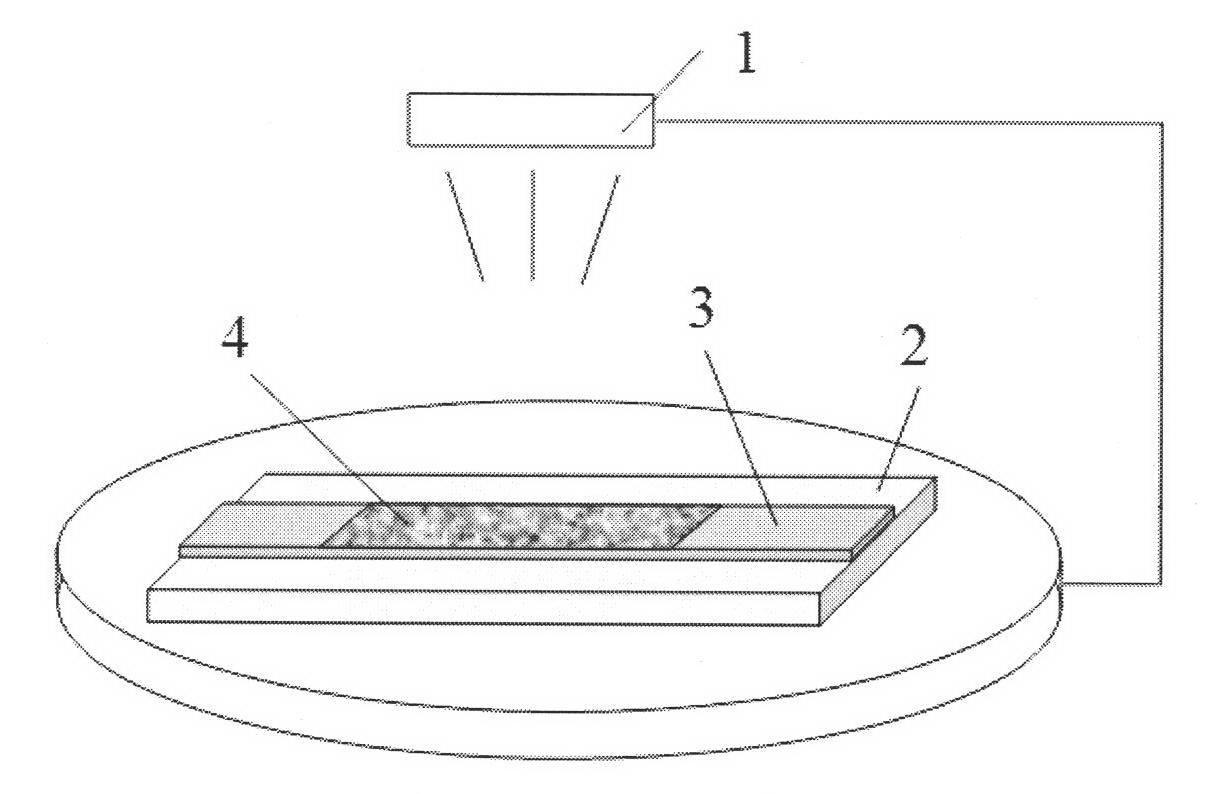

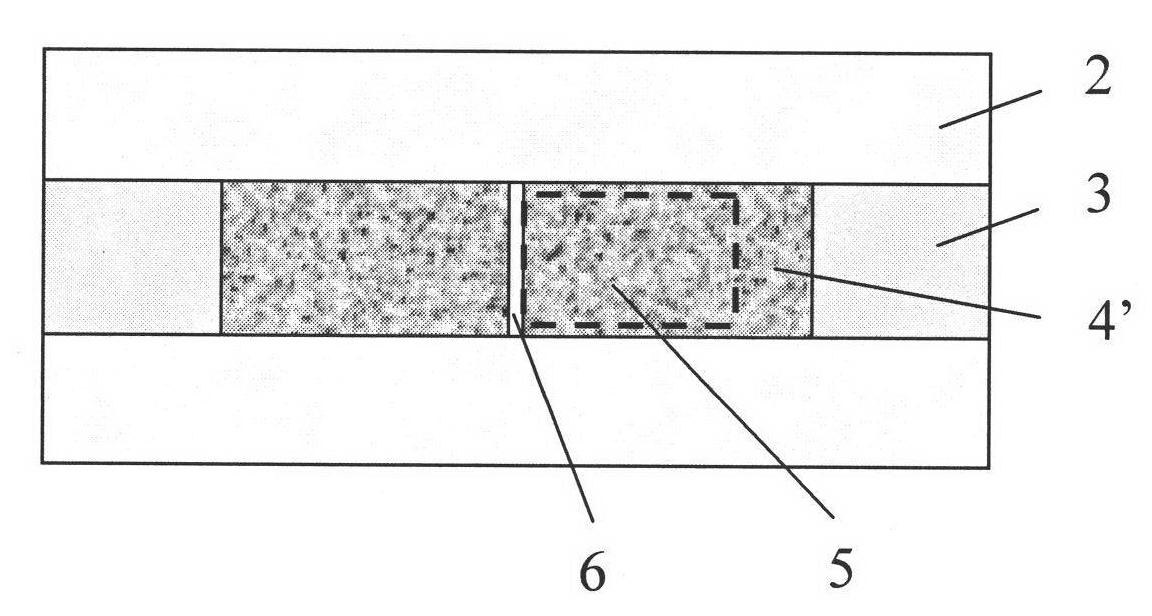

[0034] In this embodiment, speckle is used as a micro-marker. It is intended to measure the residual deformation of the copper interconnection due to the release of residual stress. The copper interconnection is deposited on a silicon substrate. The width and thickness of the copper interconnection are 20 μm and 300 nm, respectively. The distance between the centers of two adjacent copper interconnection lines is 40 μm, and the length of the copper interconnection lines is 3 mm. Place the copper interconnect sample deposited on the silicon substrate on the platform of the focused ion beam system, and select a region of a copper interconnect as the research object.

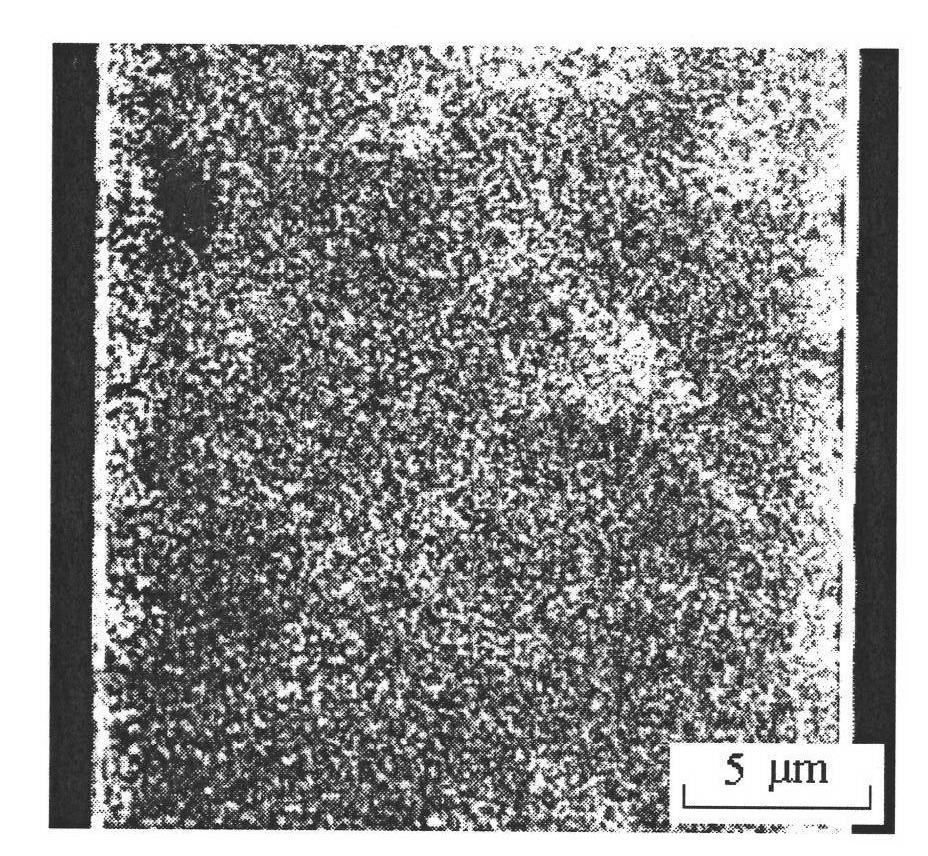

[0035] Use the ion beam in the focused ion beam system to irradiate the copper interconnection line, stop the irradiation when the speckle is clearly visible, and collect the speckle image on the copper interconnection line at this time as the micromarker image before the axial residual stress is released , the siz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Crack width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com