Shore-based feeding robot and power transmission system and control method thereof

A technology of power transmission system and control method, which is applied in the direction of control device, transportation and packaging, climate change adaptation, etc. It can solve the problems of different resistance of hydraulic motors, inconsistent wheel speeds, and different flows of four branches, so as to avoid inconsistent speeds Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

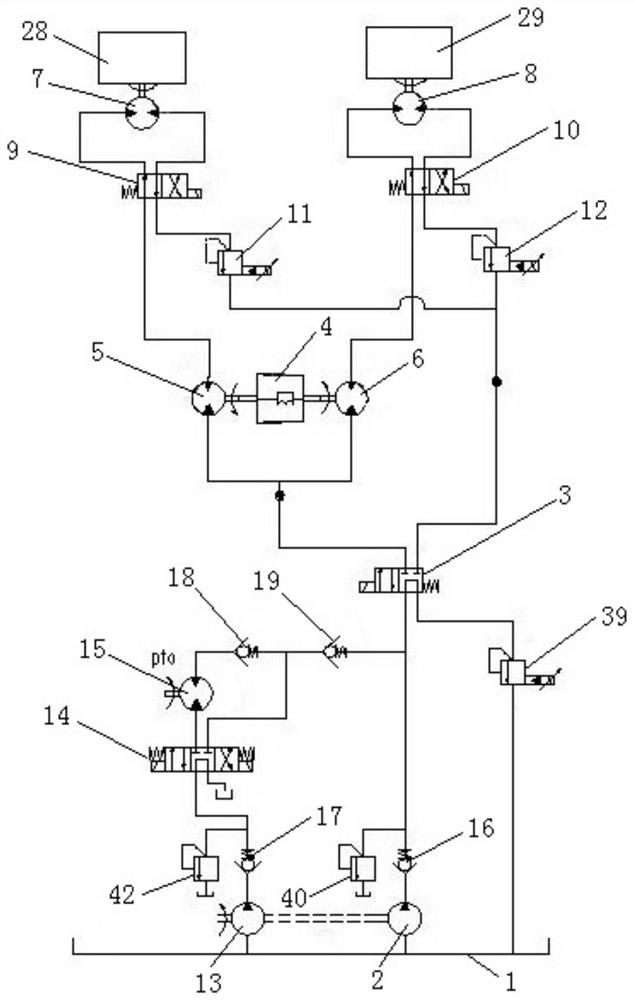

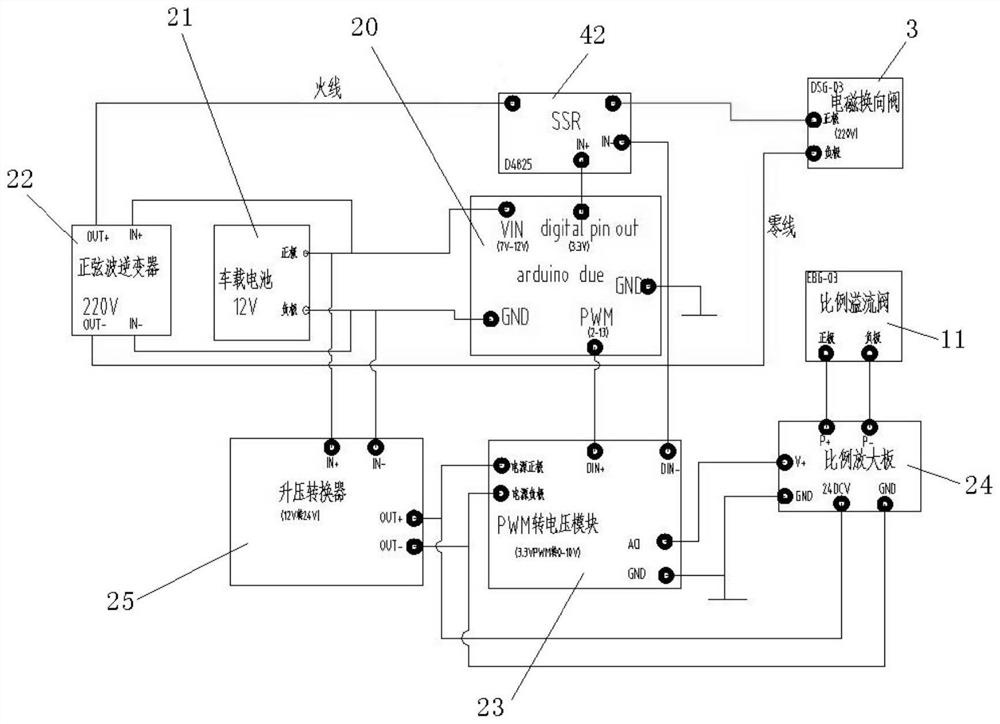

[0032] like figure 1 and figure 2 As shown, a power transmission system of a shore-based feeding robot in a preferred embodiment of the present invention includes a hydraulic oil tank 1 and a walking system, and the walking system includes a first hydraulic pump 2, a first reversing valve 3, a clutch 44, a first hydraulic pressure The motor 55, the second hydraulic motor 66, the third hydraulic motor 77 and the fourth hydraulic motor 88, the input end of the first hydraulic pump 22 is connected with the hydraulic oil tank 1, the output end of the first hydraulic pump 2 is connected with the first reversing valve 3 The oil inlet port of the first reversing valve 3 is connected with the oil inlet port of the first hydraulic motor 5 and the oil inlet port of the second hydraulic motor 6, and the oil outlet port of the first hydraulic motor 5 is connected with the oil inlet port of the second hydraulic motor 5. The oil inlets of the three hydraulic motors 7 are connected, the oi...

Embodiment 2

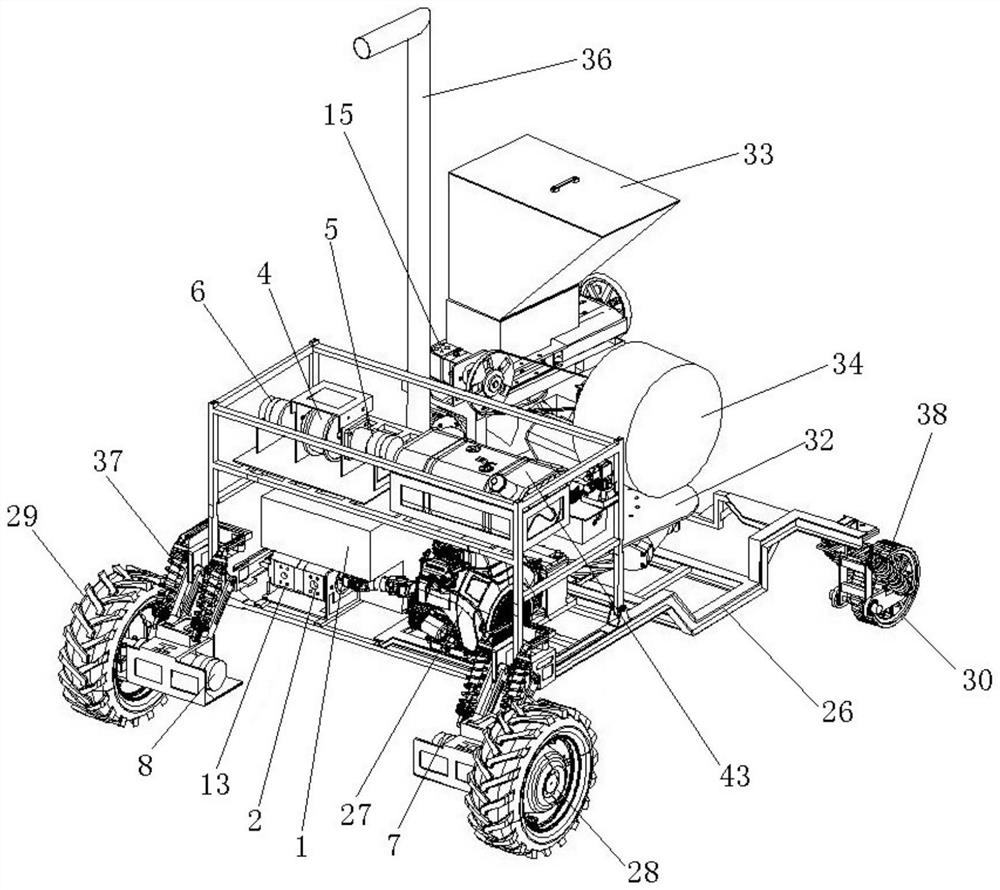

[0042] like image 3 and Figure 4 As shown, a shore-based feeding robot is preferred in this embodiment, including a vehicle frame 26, an internal combustion engine 27, a feeding device and the power transmission system of Embodiment 1, the left driving wheel 28 and the right driving wheel 29 are front wheels, and the vehicle frame 26 The front part is a double-layer structure, the internal combustion engine 27 and the first hydraulic pump 2 are located at the lower floor of the vehicle frame 26 front, and the hydraulic oil tank 1, the first hydraulic motor 5, the second hydraulic motor 6 and the clutch 4 are located at the vehicle frame 26 front. On the upper floor, the third hydraulic motor 7 and the fourth hydraulic motor 8 are installed on the bottom surface of the vehicle frame 26 , and the feeding device is located at the rear of the vehicle frame 26 . In this embodiment, the heavier hydraulic oil tank 1 is placed on the lower layer, and the other lighter hydraulic com...

Embodiment 3

[0046] A control method of a shore-based feeding robot according to a preferred embodiment of the present invention, comprising:

[0047] (1) Connect the output end of the hydraulic pump with the oil inlets of the first hydraulic motor 5 and the second hydraulic motor 6, connect the output shafts of the first hydraulic motor 5 and the second hydraulic motor 6 through the clutch 4, and the first hydraulic motor 5 and the oil outlet of the second hydraulic motor 6 communicate with the oil inlet of the third hydraulic motor 7 connected to the left driving wheel 28 and the oil inlet of the fourth hydraulic motor 8 connected to the right driving wheel 29;

[0048] Close clutch 4, start hydraulic pump, realize the same speed rotation of left driving wheel 28 and right driving wheel 29.

[0049] (2) Further, in this embodiment, the oil outlets of the third hydraulic motor 7 and the fourth hydraulic motor 8 are respectively connected with the first relief valve 11 and the second relie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com