Desulfurization and denitration system based on sensor monitoring, parameter acquisition and parameter feedback

A technology for desulfurization and denitrification and feedback parameters, which is applied in the field of desulfurization and denitrification systems, can solve problems such as the increase of ammonia escape, and achieve the effects of convenient adjustment and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

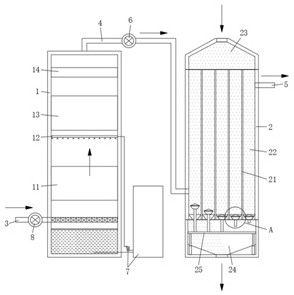

[0029] see Figure 1-Figure 2 As shown, the present invention provides a desulfurization and denitrification system based on sensor monitoring, collection and feedback parameters, and the system mainly includes the following structures arranged in sequence along the flue gas flow direction:

[0030] Air intake pipe 3; pre-processing tower 1; gas delivery pipe 4; post-processing tower 2; exhaust pipe 5.

[0031] specific:

[0032] The air inlet pipe 3 is connected to the air inlet side of the pretreatment tower 1 and is used for inputting flue gas to be treated into the pretreatment tower 1 .

[0033] In the pretreatment tower 1, a desulfurization bed 11, an atomized ammonia injection mechanism 12, an activated carbon denitrification bed 13, and a demisting drying bed 14 are sequentially arranged along the flow direction of the flue gas; wherein, the flue gas enters through the intake pipe 3, and then The desulfurization process is completed through the desulfurization bed 11...

Embodiment 2

[0038] This embodiment is a further preferred embodiment of the first embodiment above, and this embodiment includes the structure disclosed in the first embodiment above, and also includes:

[0039] The first sensor 6 installed on the gas delivery pipe 4 is used to collect the ammonia concentration in the flue gas passing through the intake pipe 3, and the post-processing tower 2 regulates the number of openings of the ammonia suction channel 22 according to the ammonia concentration.

[0040] specific:

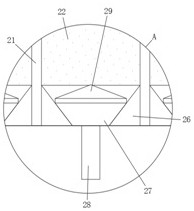

[0041] A feed bin 23 is provided at the top of the aftertreatment tower 2, and the feed bin 23 is used to introduce an ammonia adsorbent that does not absorb ammonia into each ammonia absorption channel 22;

[0042] A recovery bin 24 is arranged at the bottom of the aftertreatment tower 2, and the recovery bin 24 is used to accept the ammonia adsorbent that has adsorbed ammonia discharged from the ammonia absorption channel 22 in an open state;

[0043] The interior of the ...

Embodiment 3

[0049] This embodiment is a further preferred embodiment of the above-mentioned embodiment two, which includes the structures disclosed in the above-mentioned embodiment one and embodiment two in this embodiment, and also includes:

[0050] One side of the pretreatment tower 1 is connected with an ammonia supply assembly 7, the ammonia supply assembly 7 includes an ammonia water pump and an ammonia water tank, and the ammonia water pump is connected between the atomizing ammonia injection mechanism 12 and the ammonia water tank, and is used for spraying ammonia according to a preset Quantitatively send the ammoniacal liquor stored in the ammoniacal liquor tank into the atomized ammonia injection mechanism 12;

[0051] An ammonia water recovery area is provided at the bottom of the pretreatment tower 1, the inlet pipe 3 is located between the ammonia water recovery area and the desulfurization bed 11, and an aqueduct is connected between the ammonia water recovery area and the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com