Method for preparing super-hydrophobic functional surface of optical glass by hot press molding

A technology of optical glass and hot press forming, which is applied in glass forming, glass manufacturing equipment, glass reshaping, etc. It can solve the problems of low production efficiency, complexity, easy-to-fall off coating preparation process, etc., and achieve strong bonding force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

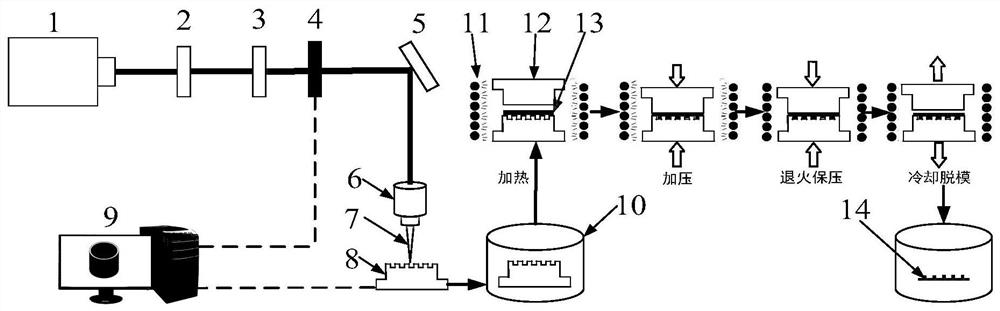

[0052] The invention provides a method for preparing the superhydrophobic functional surface of optical glass by hot pressing, comprising the following steps:

[0053] Put silicon carbide samples with a diameter of φ10mm and a height of 2.5mm into beakers filled with absolute ethanol and deionized water for ultrasonic cleaning for 3-5min, and blow dry with a hair dryer for later use;

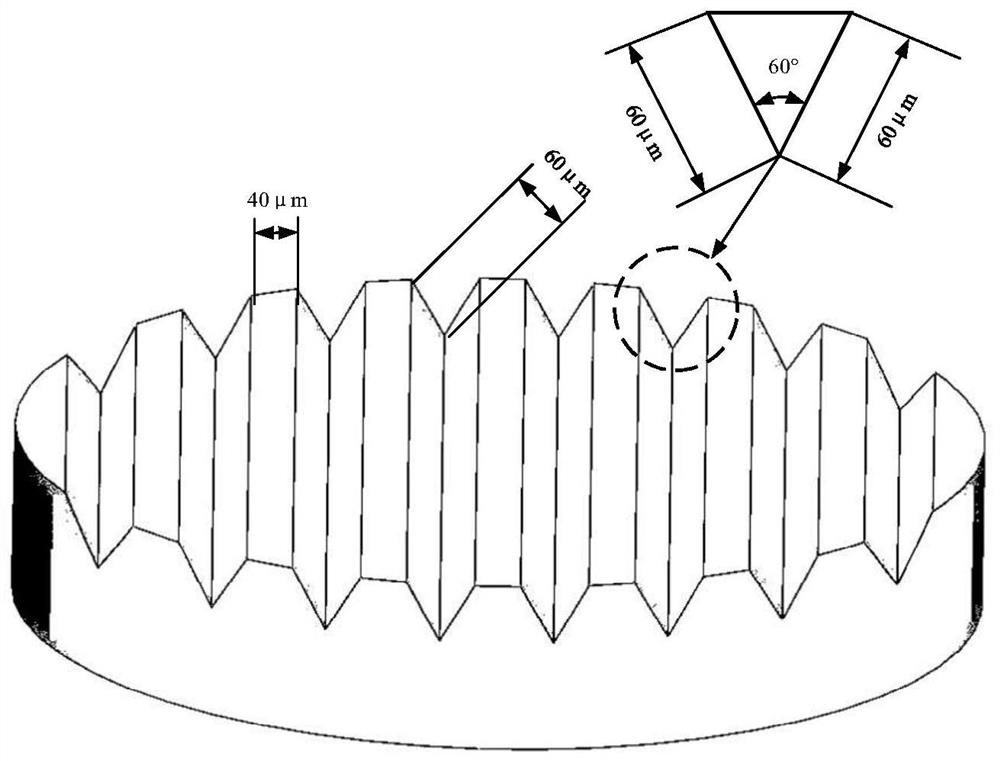

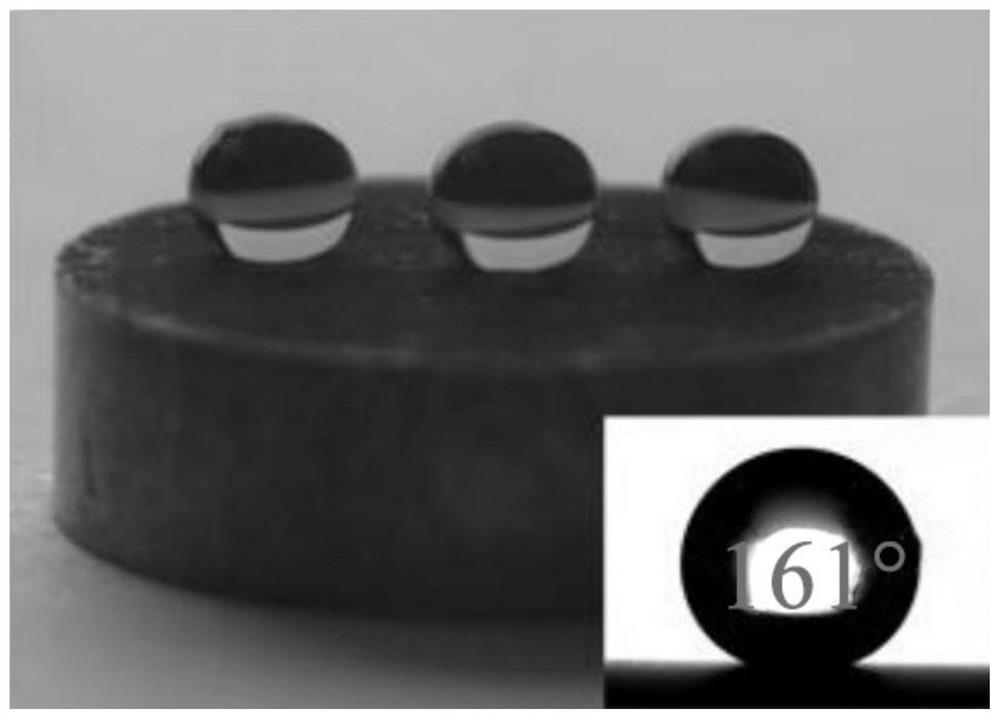

[0054] Place the silicon carbide sample on the Z platform, focus the picosecond laser beam vertically on the surface, import the micro-groove design parameters into the control software in the computer, and set the picosecond laser processing parameters according to the processing requirements. The frequency used is 50kHz, the laser power is 2W, and the scanning speed is 3000mm / s. The micro-groove structure is processed on the surface by the method of scanning multiple times line by line. For details, see figure 2 As shown, the size of the processed silicon carbide sample substrate with a micro...

Embodiment 2

[0059] The invention provides a method for preparing the superhydrophobic functional surface of optical glass by hot pressing, comprising the following steps:

[0060] Put silicon carbide samples with a diameter of φ12mm and a height of 2mm into beakers filled with absolute ethanol and deionized water for ultrasonic cleaning for 3-5min, and dry them with a hair dryer for later use;

[0061] Place the silicon carbide sample on the Z platform, focus the femtosecond laser beam vertically on the surface, import the micro-groove design parameters into the control software, and set the femtosecond laser processing parameters according to the processing requirements. The frequency used in femtosecond laser processing is 50kHz, scanning power of 20w, scanning speed of 200mm / s, and number of scanning layers of 25 to process a fine flow path structure, wherein the fine flow path structure is a rectangular groove with a height of 50 μm and a width of 150 μm, between two adjacent rectangul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com