A lead frame automatic material stacking equipment

A technology of automatic material collection and lead frame, which is applied in the direction of automatic packaging control, solid materials, packaging item types, etc., can solve the problems of poor collection effect, achieve the effect of maintaining stability, ensuring accuracy, and avoiding shaking damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

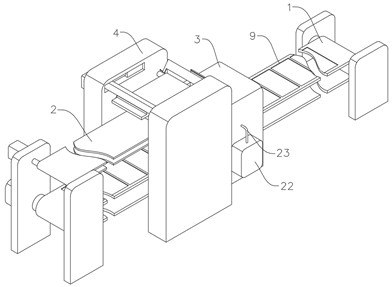

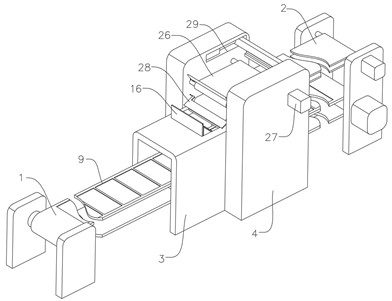

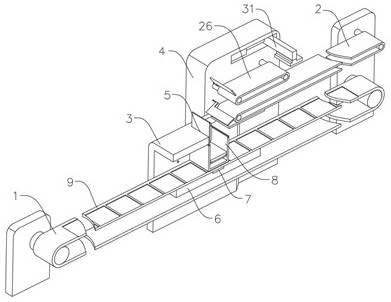

[0026] refer to Figure 1-6 , a lead frame automatic material stacking equipment, including a material box conveyor belt 1, a frame conveyor belt 2 and a processing table 3, the material box conveyor belt 1 and the frame conveyor belt 2 are fixed and driven by external equipment, and the processing table 3 Both sides are fixed with loading boards 4, the bin conveyor belt 1 runs through the processing table 3, the frame conveyor belt 2 is located in the middle of the two loading boards 4 and is rotatably connected with the two loading boards 4 through a fixed rotating shaft, and the upper end of the processing table 3 runs through A discharge port 5 is opened, and a bearing plate 6 is fixed on the inner wall of the processing table 3. The upper end of the bearing plate 6 is embedded with a No. 1 pressure sensor 7. The bearing plate 6 supports the material box conveyor belt 1, and the bearing plate 6 and the material box convey The bottom of the belt on the upper side of the bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com