Method for eliminating unit marks through start and stop of unit

A start-stop, unit technology, applied in the field of metallurgy, to achieve the effect of efficient and fast stamping, reducing the amount of degraded products, and eliminating stamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

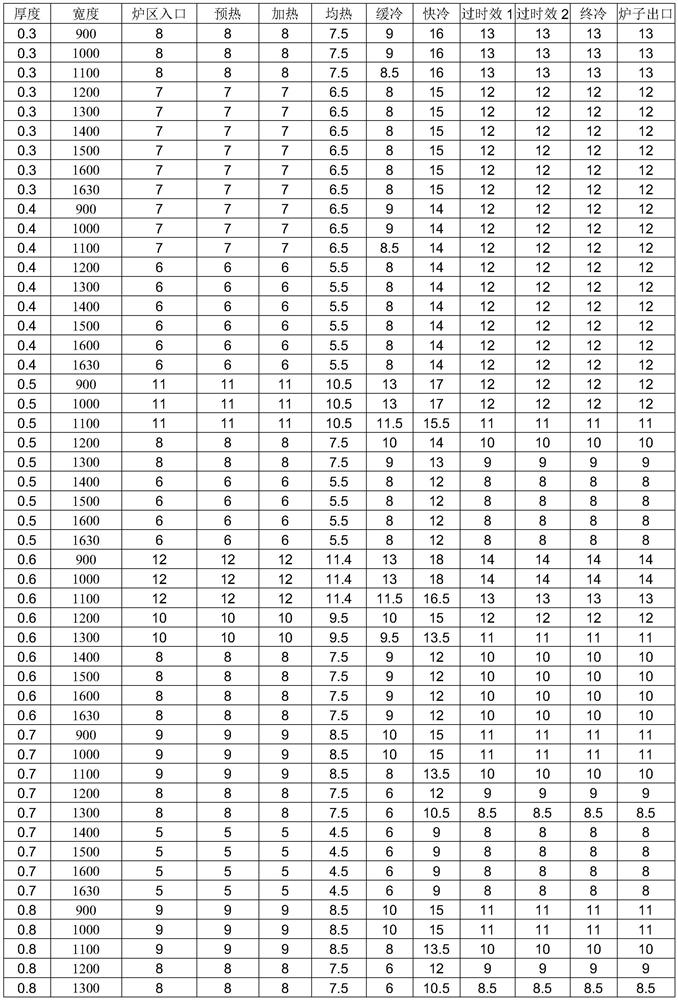

[0040] Production steel type: DC04

[0041] Specifications: 1*1300mm.

[0042] When the unit finds that there is scorching in the furnace, in order to reduce the production of defective products, the speed must be reduced to the minimum process speed of 50m / min. The tension is reduced from 7.8KN to 5.4KN, and the belt temperature is reduced to 800°C to meet the minimum annealing temperature. After the belt temperature drops to the minimum annealing temperature of 800°C, increase the tension of the hot section of the annealing furnace to 10.2KN. After the tension in the furnace area is stable, increase the furnace speed to 150m / min. After the speed is stable, press the quick stop button in the furnace area to stop the annealing furnace quickly. After the speed of the furnace zone is 0, the tension in the furnace zone is removed, and the tension is rebuilt to 10.2KN after the tension is completely removed. After the tension is stable, the furnace area directly increases the s...

Embodiment 2

[0044]Production steel type: DC01

[0045] Specification: 1*1100mm

[0046] When the unit finds that there is scorching in the furnace, in order to reduce the production of defective products, the speed must be reduced to the minimum process speed of 50m / min. The tension is reduced from 7.7KN to 5.2KN, and the belt temperature is reduced to 760°C to meet the minimum annealing temperature. After the belt temperature drops to the minimum annealing temperature of 760°C, increase the tension of each section of the annealing furnace to 9.8KN. After the tension in the furnace area is stable, increase the furnace speed to 150m / min. After the speed is stable, press the quick stop button in the furnace area to stop the annealing furnace quickly. After the speed of the furnace zone is 0, the tension in the furnace zone is removed, and the tension is rebuilt to 9.8KN after the tension is completely removed. After the tension is stable, the furnace area directly increases the speed to ...

Embodiment 3

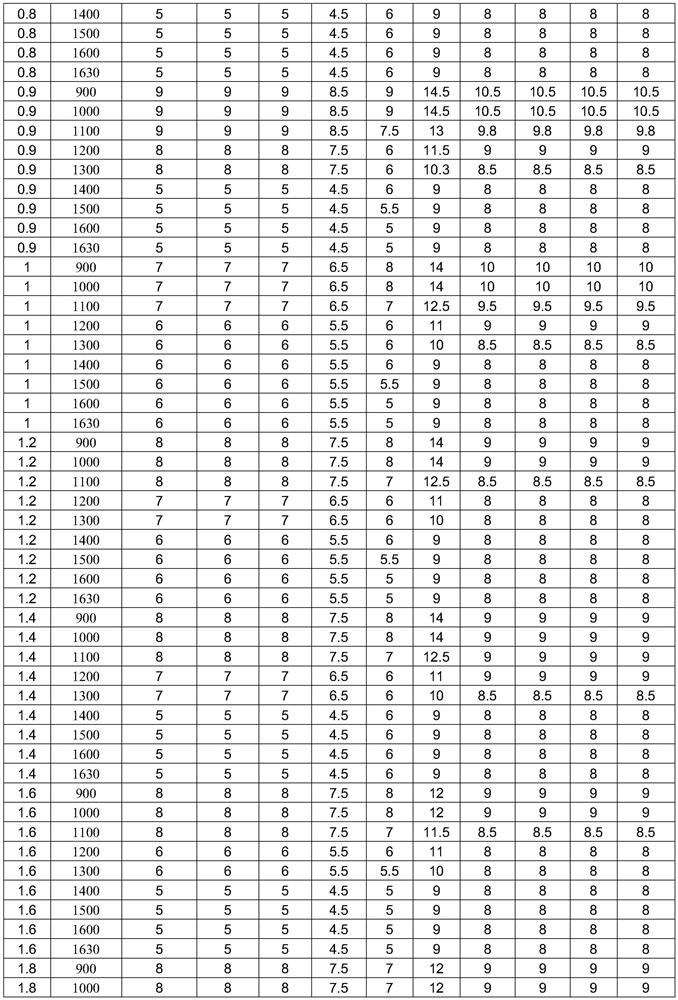

[0048] Production steel type: DC03

[0049] Specification: 1.2*1300mm

[0050] When the unit finds that the skin-passing machine is printing, firstly, the height of the front and rear anti-wrinkle rollers of the skin-passing machine will be increased from 130mm and 140mm to 160mm and 170mm, and the elongation will be increased from 0.5% to 0.6%. Increased from 70.5KN to 84.5KN. The speed of the tempering machine reciprocates between 30-550mm and starts and stops quickly. After repeated operations for more than 5 times, observe the disappearance of the printing defects at the exit of the tempering machine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com