Method for improving corrosion resistance and mechanical properties of aluminum alloy based on severe plastic deformation and high-performance corrosion-resistant aluminum alloy

A technology of severe plastic deformation and corrosion-resistant aluminum alloy, which is applied in the field of nanocrystalline metal materials, can solve problems such as the impact of unrelated material properties, achieve the effects of grain size refinement, change corrosion resistance, and improve mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A high-performance corrosion-resistant aluminum alloy provided by the present embodiment is obtained according to the following method:

[0037] (1) Obtaining T351-2024 aluminum alloy: In terms of mass percentage, T351-2024 aluminum alloy includes 4.63% Cu, 0.15% Fe, 1.51% Mg, 0.66% Mn, 0.08% Si, 0.05% Zn, and other elements <0.05% , and the rest are Al. The T351-2024 aluminum alloy is a disc with a diameter of 9.8 mm, a height of 0.82 mm, and a pre-stretching deformation of 2%.

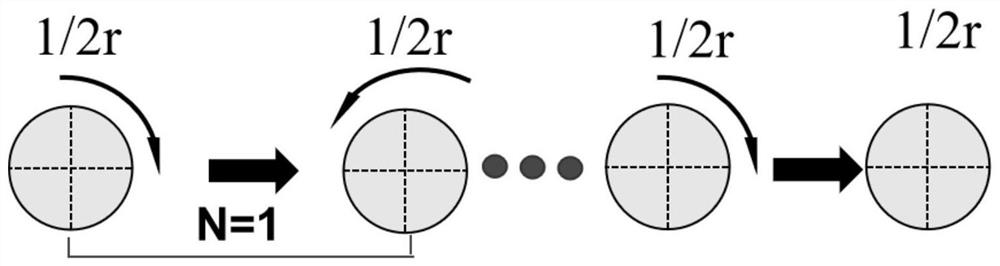

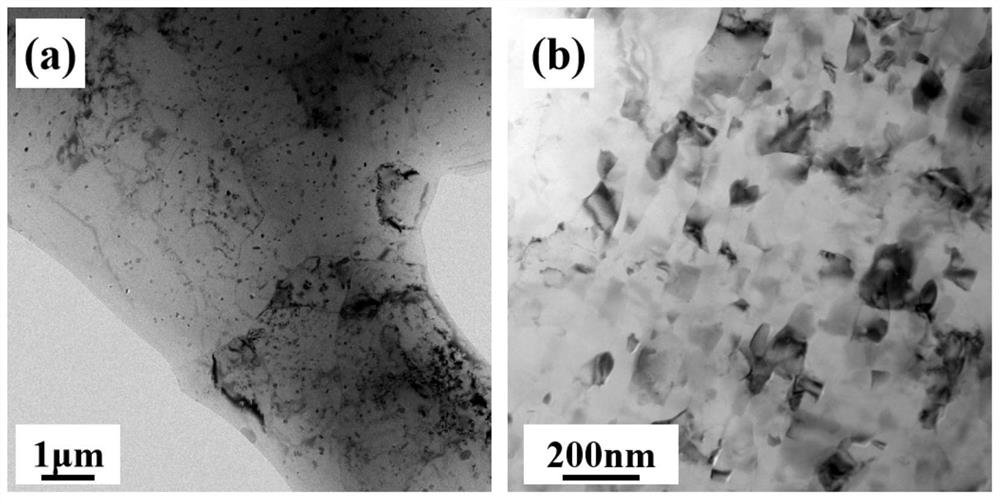

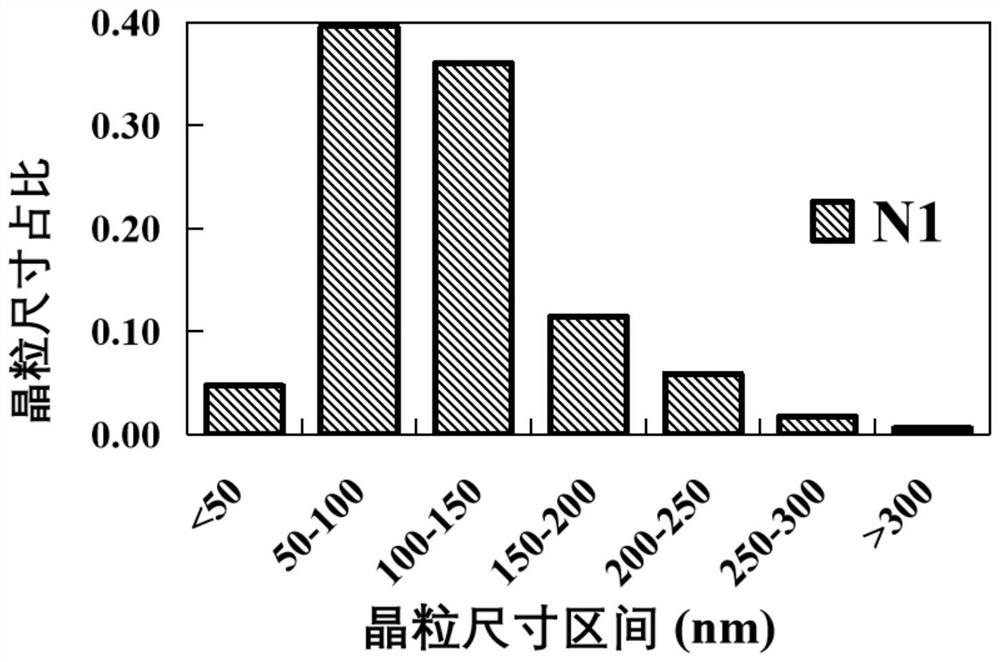

[0038] (2) Put the T351-2024 aluminum alloy into the high-pressure torsion system with grooves on both the upper and lower anvils. The diameter of the groove is 10mm. After the T351-2024 aluminum alloy is placed in the middle of the upper and lower anvils, it is basically coupled. And there is a small margin space. The high-pressure torsional deformation is carried out at a high-pressure torsional deformation pressure of 6 Gpa and a torsional deformation speed of 1 r / min, and the torsional cyc...

Embodiment 2

[0040] A high-performance corrosion-resistant aluminum alloy provided by the present embodiment is obtained according to the following method:

[0041] (1) Obtaining T351-2024 aluminum alloy: In terms of mass percentage, T351-2024 aluminum alloy includes 4.63% Cu, 0.15% Fe, 1.51% Mg, 0.66% Mn, 0.08% Si, 0.05% Zn, and other elements <0.05% , and the rest are Al. The T351-2024 aluminum alloy is a disc with a diameter of 9.8 mm, a height of 0.82 mm, and a pre-stretching deformation of 2%.

[0042] (2) Put the T351-2024 aluminum alloy into the high-pressure torsion system with grooves on both the upper and lower anvils. The diameter of the groove is 10mm. After the T351-2024 aluminum alloy is placed in the middle of the upper and lower anvils, the basic coupling is performed. And there is a small margin space. The high-pressure torsional deformation is carried out under the high-pressure torsional deformation pressure of 6 Gpa and the torsional deformation speed of 1 r / min, and ...

Embodiment 3

[0044] (1) Obtaining T351-2024 aluminum alloy: In terms of mass percentage, T351-2024 aluminum alloy includes 4.63% Cu, 0.15% Fe, 1.51% Mg, 0.66% Mn, 0.08% Si, 0.05% Zn, and other elements <0.05% , and the rest are Al. The T351-2024 aluminum alloy is a disc with a diameter of 9.8 mm, a height of 0.82 mm, and a pre-stretching deformation of 2%.

[0045] (2) Put the T351-2024 aluminum alloy into the high-pressure torsion system with grooves on both the upper and lower anvils. The diameter of the groove is 10mm. After the T351-2024 aluminum alloy is placed in the middle of the upper and lower anvils, the basic coupling is performed. And there is a small margin space. The high-pressure torsional deformation is carried out at a high-pressure torsional deformation pressure of 6 Gpa and a torsional deformation speed of 1 r / min, and the torsional cycle is 3 times to obtain a high-performance corrosion-resistant aluminum alloy. Among them, one torsional deformation cycle is to first ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| corrosion potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com