Radiant tube burner with high-temperature ejector and use method of radiant tube burner

A radiant tube and ejector technology, which is applied in the field of burners, can solve the problems of increasing air volume, not saving energy, and low flue gas ejection and return rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

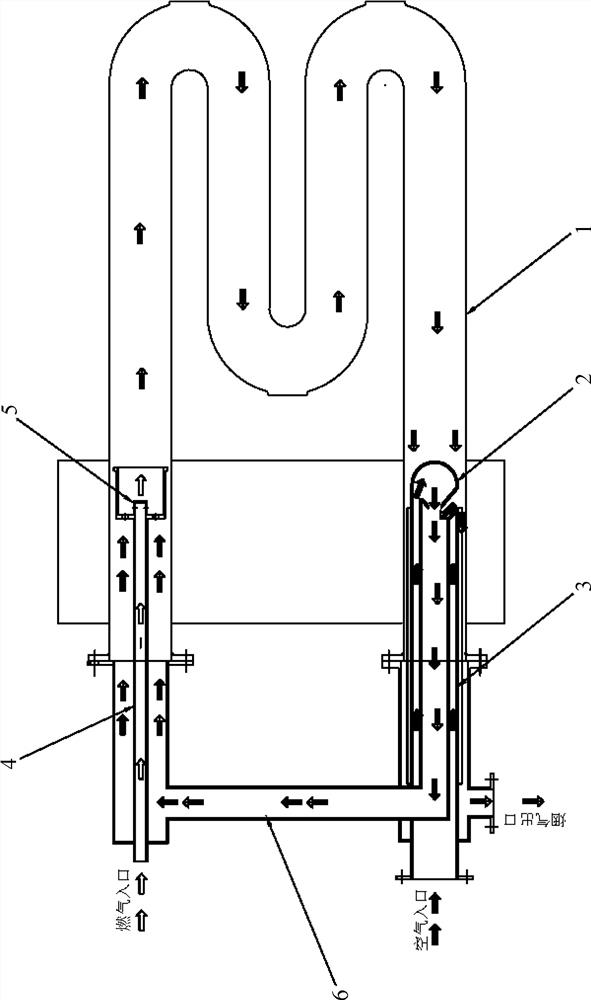

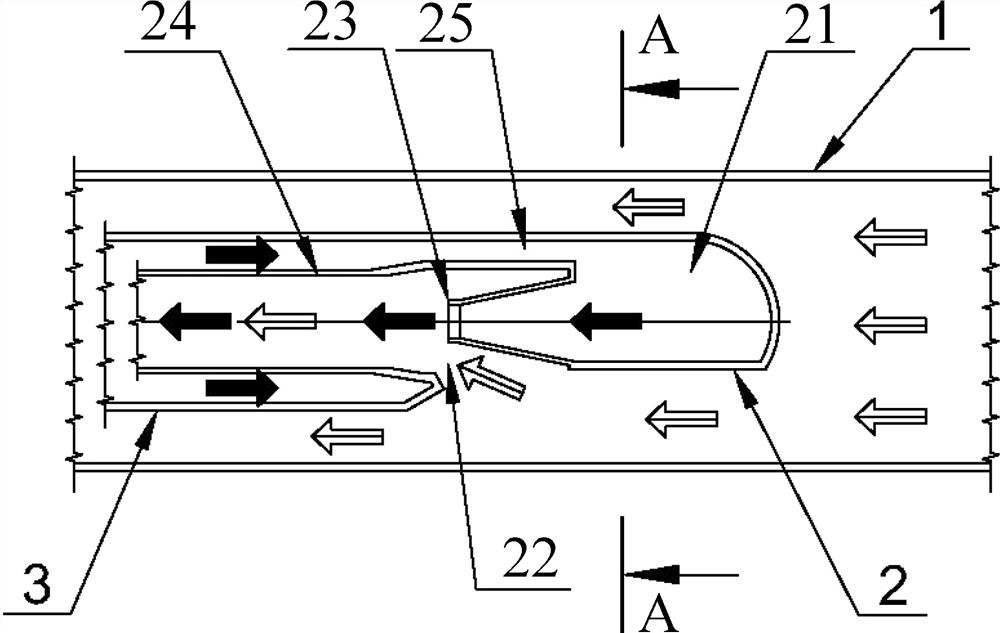

[0028] A tape high temperature radiant tube burner ejector, comprising a radiant tube 1, the high-temperature ejector 2, the heat exchanger 3, the burner body 4, the combustion burner head 5 and the communication pipe 6, as figure 1 and figure 2 , The specific configuration is:

[0029] Both ends of the radiant tube 1 are gas inlet and flue gas outlet;

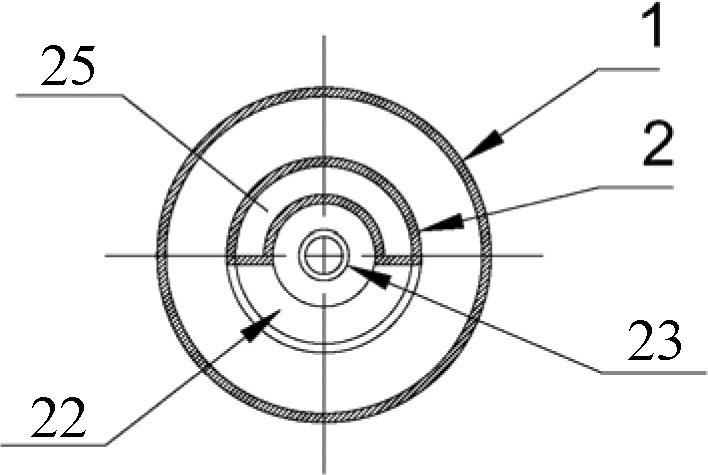

[0030] Temperature ejector 2 includes an air confluence chamber 21, gas ejector inlet channel 22, the air ejector nozzle 23, ejector mixing tube 24 and the air confluent passage 25, the air confluence chamber 21 the inlet end is larger than that connecting the air confluent passage 25 the area of the outlet end, the inlet end of the air chamber 21 is connected confluent confluent air outlet end of the passage 25, the confluent air in the air chamber cavity 21 merging region other than the flue gas passage 25 constituting the ejector inlet channel 22, the air chamber 21 confluent an air outlet end the ejector nozzle 23, ejector m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com