MOF material, preparation method thereof, proton exchange membrane, preparation method thereof, and fuel cell

A proton exchange membrane and fuel cell technology, applied in fuel cells, fuel cell parts, circuits, etc., can solve the problems of reducing proton conductivity and adverse effects on device performance, so as to improve proton conductivity and stabilize proton transport performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

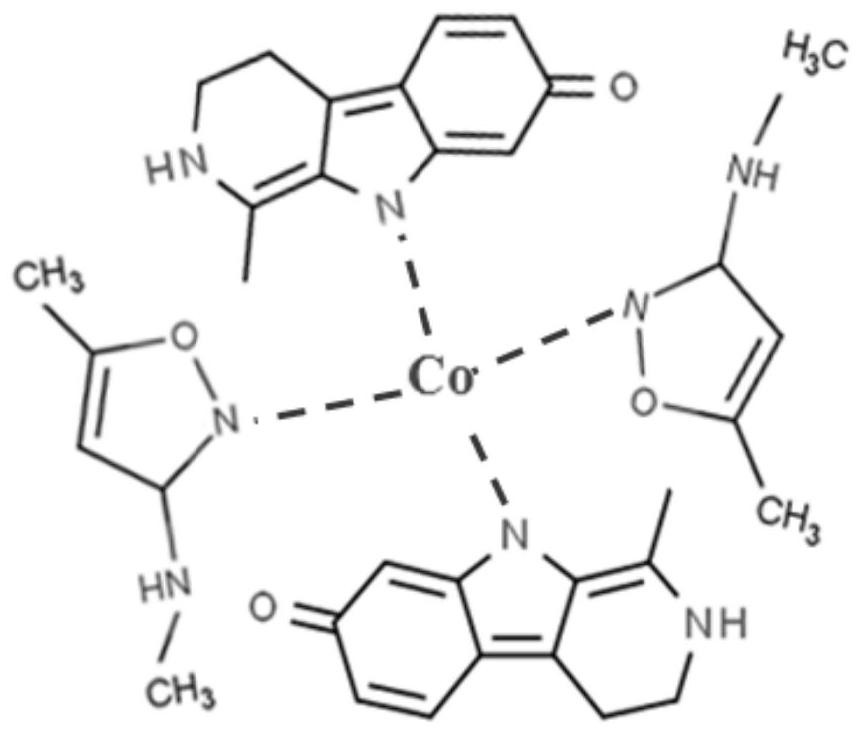

[0043] The present invention also provides a preparation method for the above-mentioned MOF material, mainly using a solvothermal method, specifically comprising the following steps:

[0044] Step 1: Mix metal cobalt salt, norhalamine and methyl-(5-methyl-isoxazol-3-yl)-amine in a solvent to obtain a mixed solution.

[0045] In a practicable embodiment, the solvent is water, and the metal cobalt salt is a water-soluble metal cobalt salt, that is, cobalt ions can be formed in an aqueous solution, and the mixed solution is adjusted to be alkaline, so that the metal cobalt ions can form hydroxide substances, involved in solvothermal reactions.

[0046] Specifically, in this embodiment, the metal cobalt salt is CoCl 2 , the pH value of the mixed solution is 8-10, specifically, it can be 8, 9 or 10, and the pH of the mixed solution can be adjusted with an alkaline solution, such as NaOH, KOH or ammonia water.

[0047] Step 2: placing the mixed solution in a closed space for solvo...

Embodiment 1

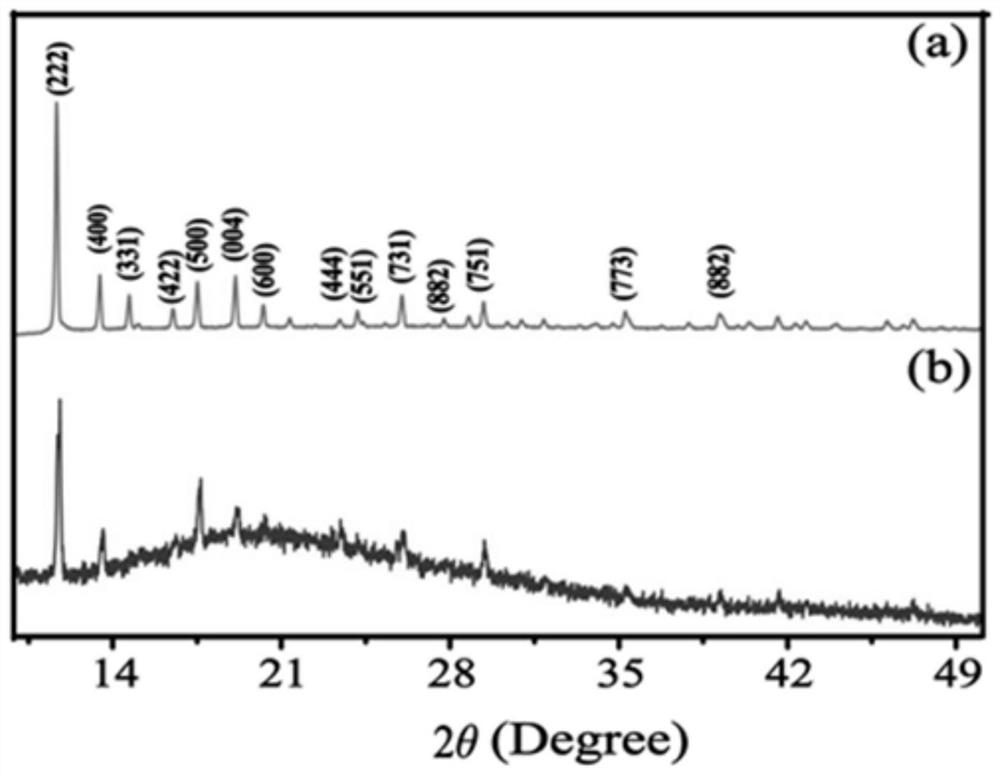

[0063] 1) Take 0.4mmol CoCl 2 , 0.1 mmol A and 0.4 mmol B were dispersed in 40 ml of distilled water, stirred thoroughly at ambient temperature for 3 hours, and the pH value was adjusted to 8.5 with NaOH aqueous solution to obtain a suspension.

[0064] 2) the suspension is sealed in a 50ml stainless steel reaction vessel lined with polytetrafluoroethylene, heated in a 430K oven to carry out solvothermal reaction, the reaction is carried out for 5 days under autogenous pressure and static conditions, and then the container is placed in the oven with Cooling slowly at 5K per hour to 298K, and then turning on, collected the MOF material as yellow crystals.

[0065] 3) The yellow crystals were vacuum-dried in a vacuum oven at 90°C for 24 hours to obtain a white solid, which was the final MOF material.

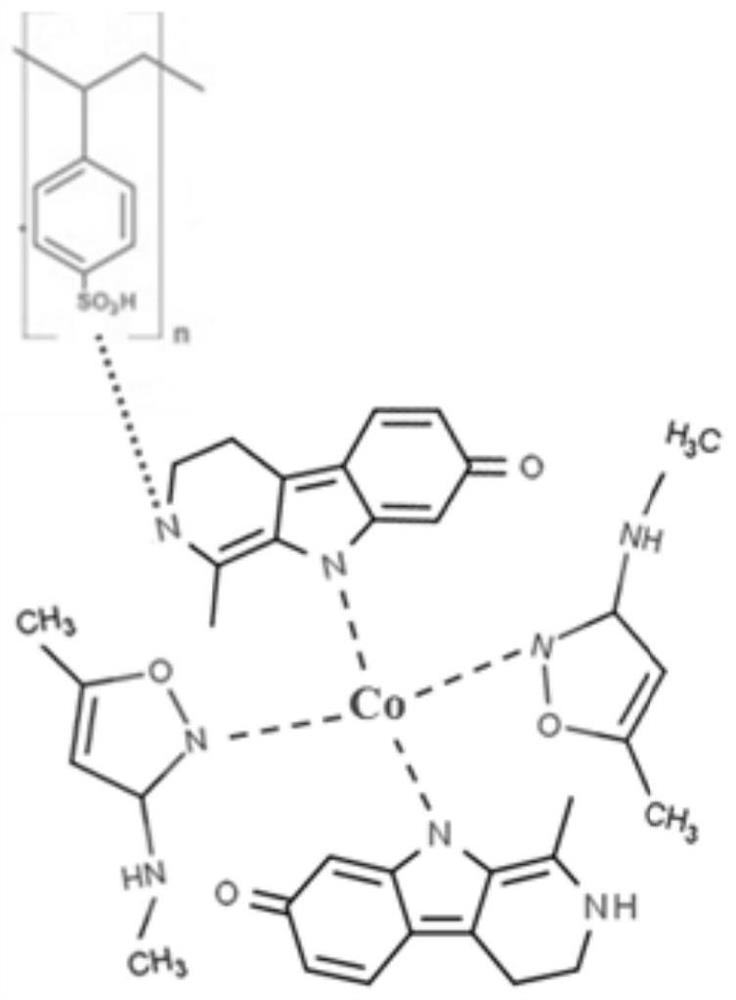

[0066] 4) Mix 1g of PSS powder (Mw=50,000g / mol, Mn=14000, IEC is 1.4meq g -1 , purchased from Germany FuMA-Tech, GmbH) was dissolved in 20mL dimethylacetamide (DMAc) solvent, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ionic conductivity | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com