Substance for solving leakage problem and preparation method thereof

A substance and problem technology, applied in the field of substances and their preparation for leakage problems, can solve problems such as affecting later use and management, failing to achieve expected repair effects, and increasing engineering maintenance costs, achieving strong practicability and functionality, The effect of wide application range and shortened setting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

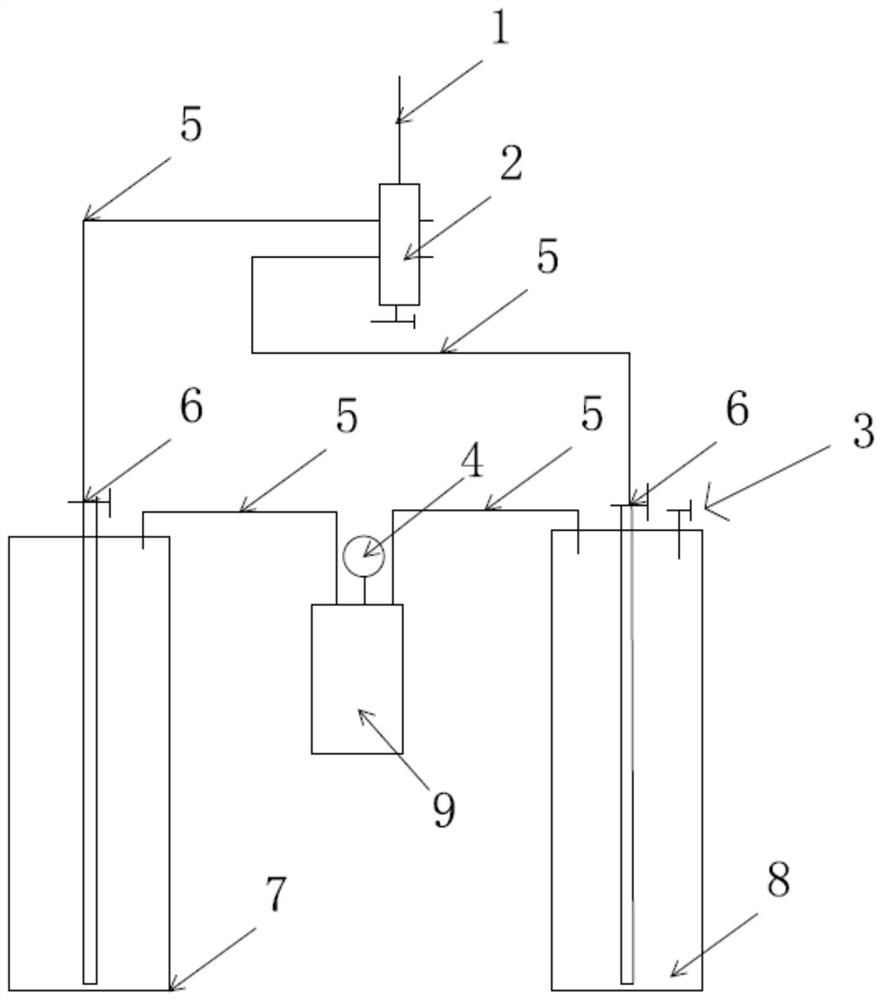

[0023] When using the above ingredients to prepare the anti-seepage slurry, the following construction steps are included:

[0024] 1) Use a balance to weigh quantitative ammonium acrylate, methylene bis, ammonium chloride, strong coagulant ferrous sulfate, water, ammonium persulfate, and water, and then sort and store them to ensure clean, pollution-free, and loss-free; or

[0025] Use a balance to weigh quantitative ammonium acrylate, methylenebis, triethanolamine, water, ammonium persulfate, and water, and then sort and store them to ensure clean, pollution-free, and loss-free;

[0026] 2) Prepare the weighed components into liquid A and liquid B respectively, stir evenly, and after completely dissolving in water, put them into cylinder A and cylinder B of the high-pressure energy storage grouting instrument respectively, tighten the cylinder cap, and draw out Keep the hose connecting the air storage tank and the spray gun in the two barrels clean and unobstructed, and tigh...

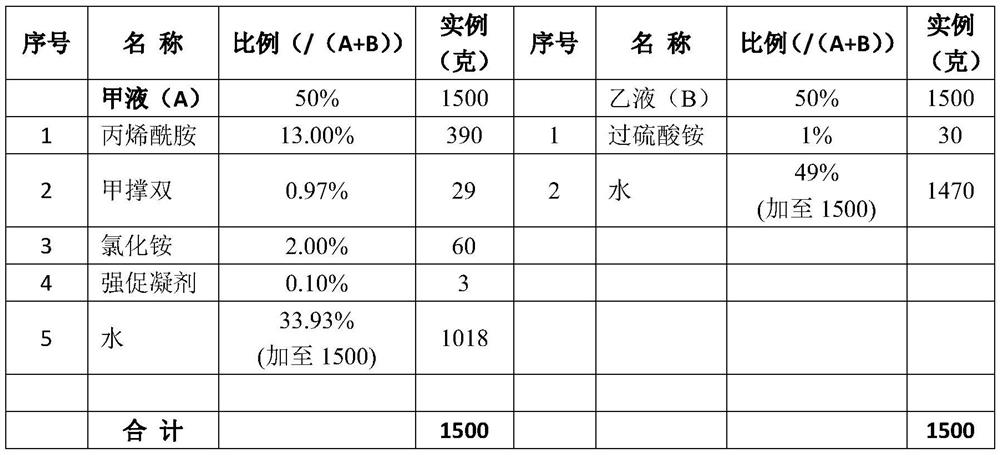

Embodiment 1

[0032] The total weight of the configuration solution is 3000 grams, the A liquid and the B liquid are each 1500 grams, and the concentration is controlled at about 17%. Gel time: 1-3 seconds.

[0033]

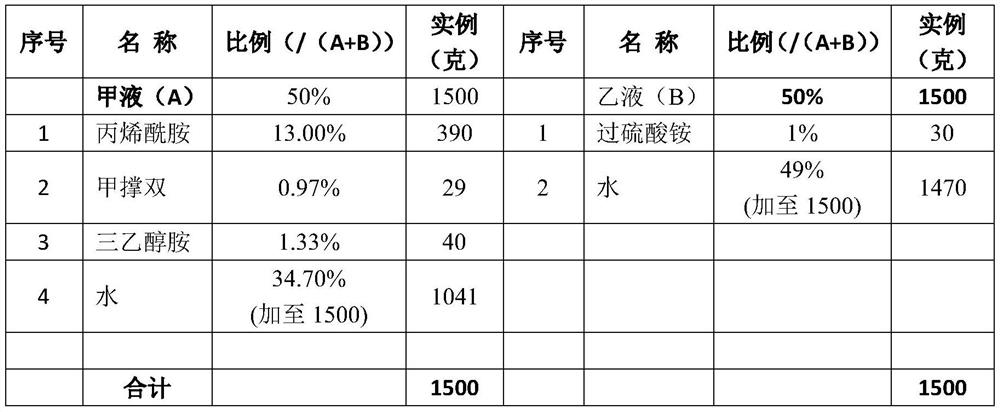

Embodiment 2

[0035] The total weight of the configuration solution is 3000 grams, the weights of liquid A and liquid B are each 1500 grams, and the concentration is controlled at about 17%. Gel time: more than 10 to 50 seconds.

[0036]

[0037] The present invention is widely used, and is embodied in:

[0038] It can carry out anti-seepage and plugging construction under high water head conditions, and is not affected by the open water level or groundwater level. It can be constructed under any water head, and the biggest feature is that it can leak water on the back water surface (commonly known as "reverse water leakage") construction under the environment;

[0039] The formulation provided by the invention has water solubility and hydrophilicity, and is suitable for construction in a water environment.

[0040] Specific application cases:

[0041] Various anti-seepage methods have their own advantages and disadvantages. The slurry formed by the present invention is sprayed at hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com