Thermally activated delayed fluorescent material and preparation method and application thereof

A technology of thermally activated delayed fluorescent materials, applied in the fields of luminescent materials, chemical instruments and methods, semiconductor/solid-state device manufacturing, etc., can solve the problems of short thermally activated delayed fluorescence lifetime, difficult synthesis, disappearance of afterglow, etc., and achieve high practical promotion The effect of application value, low preparation cost and low usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

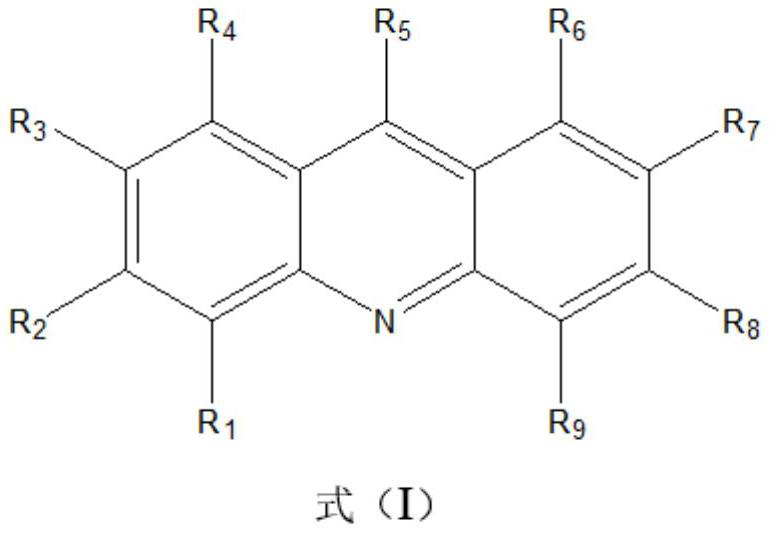

[0035] The preparation method of the thermally activated delayed fluorescent material of this embodiment includes the following steps: polyethylene-polyvinyl alcohol copolymer, figure 1 Compound No. 1 in the method is dissolved together in water to form a mixed solution, and after evaporating the water, it is dried to obtain a heat-activated delayed fluorescent material;

[0036] Wherein, every 1KG polyethylene-polyvinyl alcohol copolymer is mixed with 0.25mmol No. 1 compound;

[0037] The molar percentage of polyethylene monomer in the polyethylene-polyvinyl alcohol copolymer is 20%, and the molar percentage of polyvinyl alcohol monomer is 80%.

[0038] The thermally activated delayed fluorescent material of the present embodiment is subjected to a performance test, wherein the fluorescence spectrum and quantum efficiency are measured by a steady-state fluorescence spectrometer, such as the FLS-1000 steady-state fluorescence spectrometer in Edinburgh, UK, wherein the fluoresc...

Embodiment 2

[0041] The preparation method of the thermally activated delayed fluorescent material of this embodiment includes the following steps: polyethylene-polyvinyl alcohol copolymer, figure 1 Compound No. 1 in the method is dissolved together in water to form a mixed solution, and after evaporating the water, it is dried to obtain a heat-activated delayed fluorescent material;

[0042] Wherein, every 1KG polyethylene-polyvinyl alcohol copolymer is mixed with 10mmol No. 1 compound;

[0043] The molar percentage of polyethylene monomer in the polyethylene-polyvinyl alcohol copolymer is 20%, and the molar percentage of polyvinyl alcohol monomer is 80%.

[0044] Using the same test method as in Example 1, it was determined that the thermally activated delayed fluorescent material prepared in this example had a maximum fluorescence / thermally activated delayed fluorescence wavelength of 502 nm and a quantum efficiency of 35%. Compared with Example 1, in this example, because the amount o...

Embodiment 3

[0046] The preparation method of the thermally activated delayed fluorescent material of this embodiment includes the following steps: polyethylene-polyvinyl alcohol copolymer, figure 1 The No. 1 compound in the method is dissolved in ethylene glycol together to form a mixed solution, and after evaporating ethylene glycol, it is dried to obtain a heat-activated delayed fluorescent material;

[0047] Wherein, every 1KG polyethylene-polyvinyl alcohol copolymer is mixed with 10mmol No. 1 compound;

[0048] The molar percentage of polyethylene monomer in the polyethylene-polyvinyl alcohol copolymer is 20%, and the molar percentage of polyvinyl alcohol monomer is 80%.

[0049] Using the same test method as in Example 1, it was determined that the thermally activated delayed fluorescent material prepared in this example had a maximum fluorescence / thermally activated delayed fluorescence wavelength of 5485 nm and a quantum efficiency of 34%. Compared with Example 1, in this example,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quantum efficiency | aaaaa | aaaaa |

| quantum efficiency | aaaaa | aaaaa |

| quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com