High-pressure common-rail oil injector based on electromagnetic proportional valve oil injection rule flexibility and controllability

A technology of electromagnetic proportional valve and fuel injection law, which is applied in the direction of machine/engine, fuel injection device, engine components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in more detail below in conjunction with accompanying drawing example:

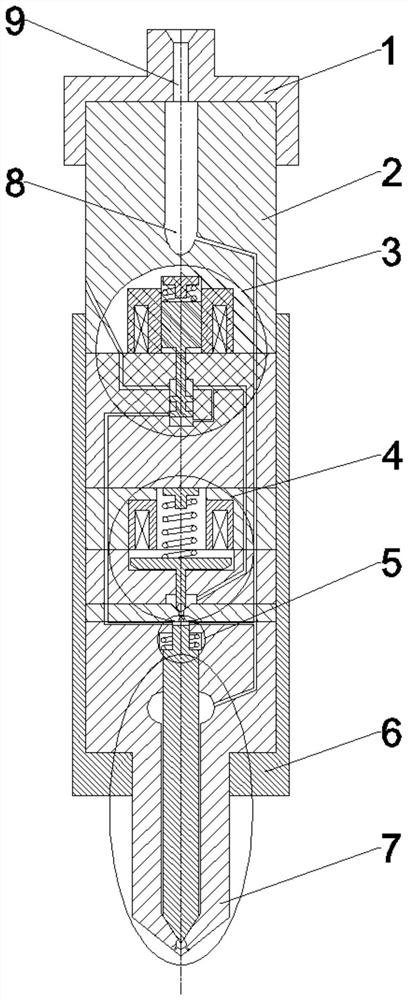

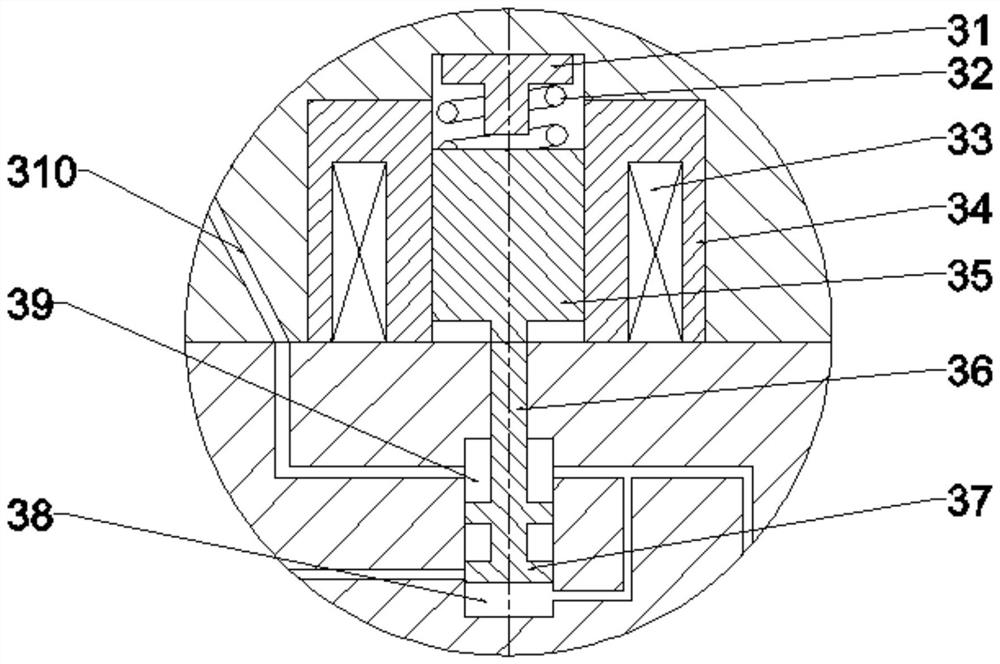

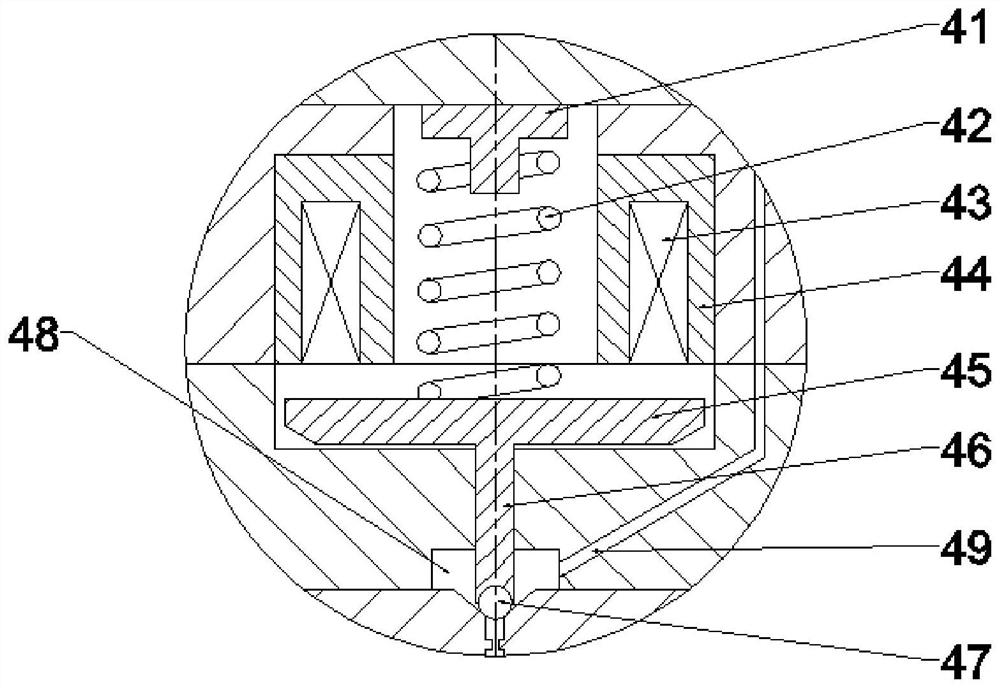

[0019] combine Figure 1-5 , the present invention is made up of high-pressure fuel inlet connector 1, fuel injector body 2, additional electromagnetic proportional valve part 3, solenoid valve part 4, control chamber 5, tight cap 6, fuel injection nozzle part 7, and pressure accumulator chamber 8. The high-pressure fuel inlet joint 1 and the injector body 2 are sealed through threads, and a high-pressure fuel flow channel 9 is set in the high-pressure fuel oil inlet joint 1, and the high-pressure fuel flow channel 9 is connected to the pressure accumulation chamber 8 in the injector body 2 connected. An additional electromagnetic proportional valve part 3 is provided below the accumulator chamber 8 . The additional electromagnetic proportional valve part 3 is installed between the fuel injector body 2 and the electromagnetic valve part 4, and its main structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com