Micro-damage cutting system and method for photovoltaic crystalline silicon solar cell

A solar cell, photovoltaic crystalline silicon technology, applied in photovoltaic power generation, circuits, electrical components, etc., can solve problems such as reducing production safety, affecting cell strength, reducing conversion efficiency, etc., and reducing heat-affected areas and cross-section microcracks , Avoid the risk of cracking, improve the effect of product strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

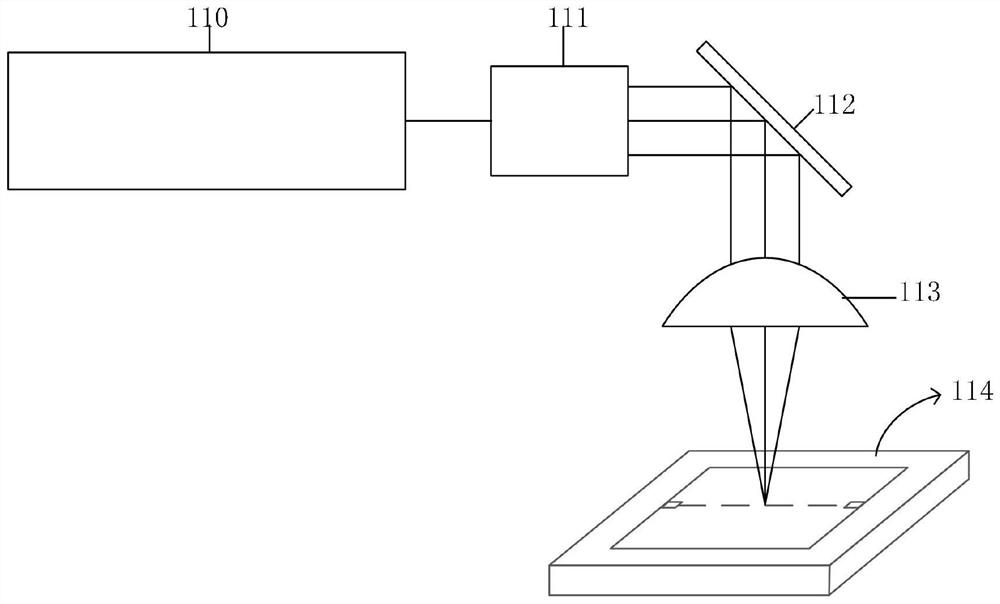

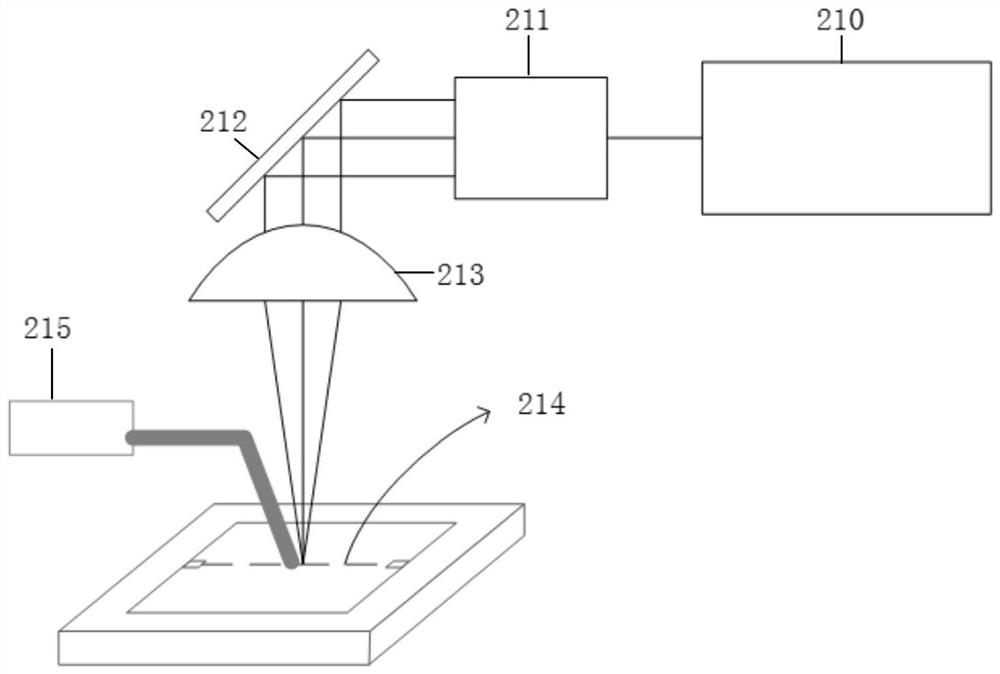

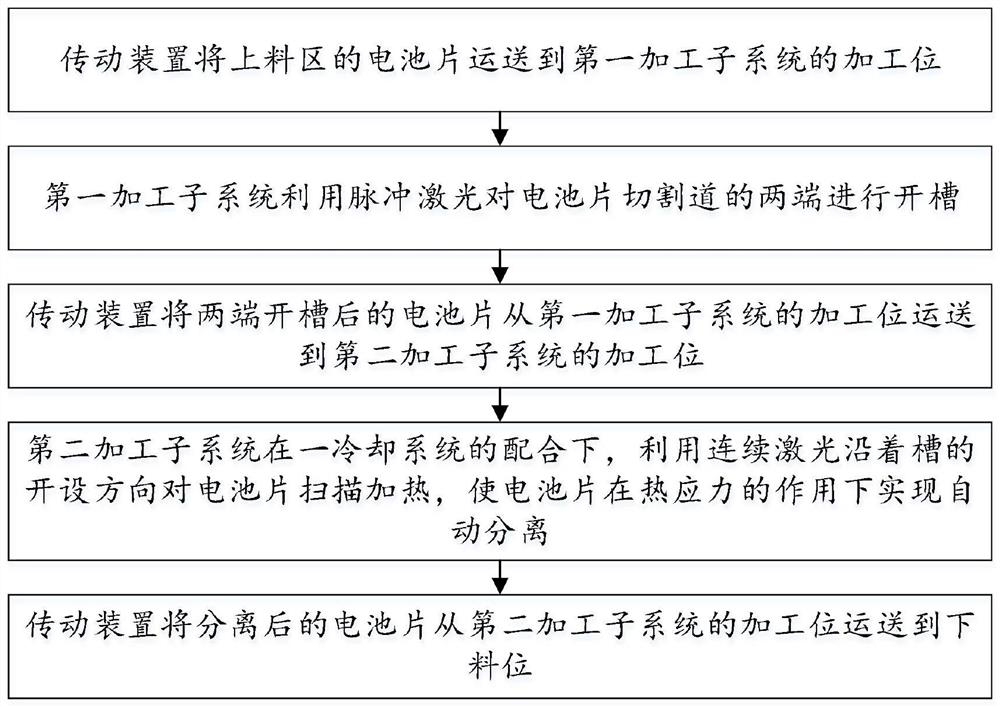

[0046] A micro-damage cutting system for photovoltaic crystalline silicon solar cells, such as Figure 1 to Figure 10 As shown, the micro-damage cutting system for photovoltaic crystalline silicon solar cells includes a first processing subsystem, a second processing subsystem and a transmission device; slotting, the second processing subsystem is used to scan and heat the cells along the opening direction of the slots with a continuous laser with the cooperation of a cooling system 215, so that the cells can be automatically separated under the action of thermal stress , the transmission device is used to transport the battery slices at the loading level to the processing position of the first processing subsystem, or transport the battery slices with both ends slotted from the processing position of the first processing subsystem to the The processing station of the second processing subsystem, or transport the separated battery slices from the processing station of the seco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com