A high-speed hose production line

A production line and hose technology, applied in the direction of tubular items, coatings, household appliances, etc., can solve problems such as shortage, achieve the effect of ingenious structure, improve transportation efficiency, and avoid bounces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

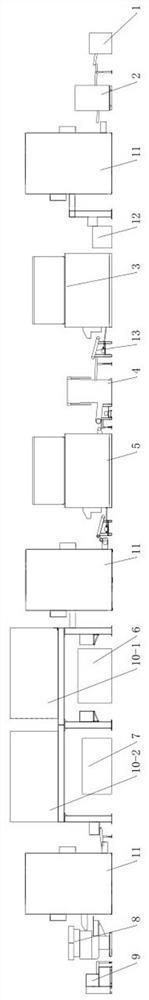

[0071] See figure 1 The present invention is in sequentially disposed provided a cold extrusion machine 1, a threaded machine 2, an annealing furnace 3, an inner sprayer 4, a curing furnace 5, a primer 6, a first oven 10-1, a multicolor printing machine 7, a second oven 10-2, twoid machine 8 and tail coatings 9. The first oven 10-1 and the second oven 10-2 are respectively fixed above the basement machine 6 and the multi-color printer 7, and one type of soft tube memory 11 is disposed between the threaded machine 2 and the annealing furnace 3. A soft tube memory 11 is disposed between the cured furnace 5 and the bottom color machine 6, and a soft tube memory is provided between the second oven 10-2 and the twoidal machine 8 above the multicolor printing press. 11. One side of the annealing furnace 3 and the cured furnace 5 is provided with a hose feed apparatus 12, and the other side of the annealing furnace 3 and the cured furnace 5 is provided with a hose discharge device 13.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com