Acoustic metamaterial noise reduction damping plate

An acoustic metamaterial and damping plate technology, applied in the field of acoustic metamaterials, can solve the problems of single noise reduction frequency, thick and heavy noise reduction effect, etc., and achieve the effect of optimizing noise reduction performance, improving processing effect, and improving sound insulation coefficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

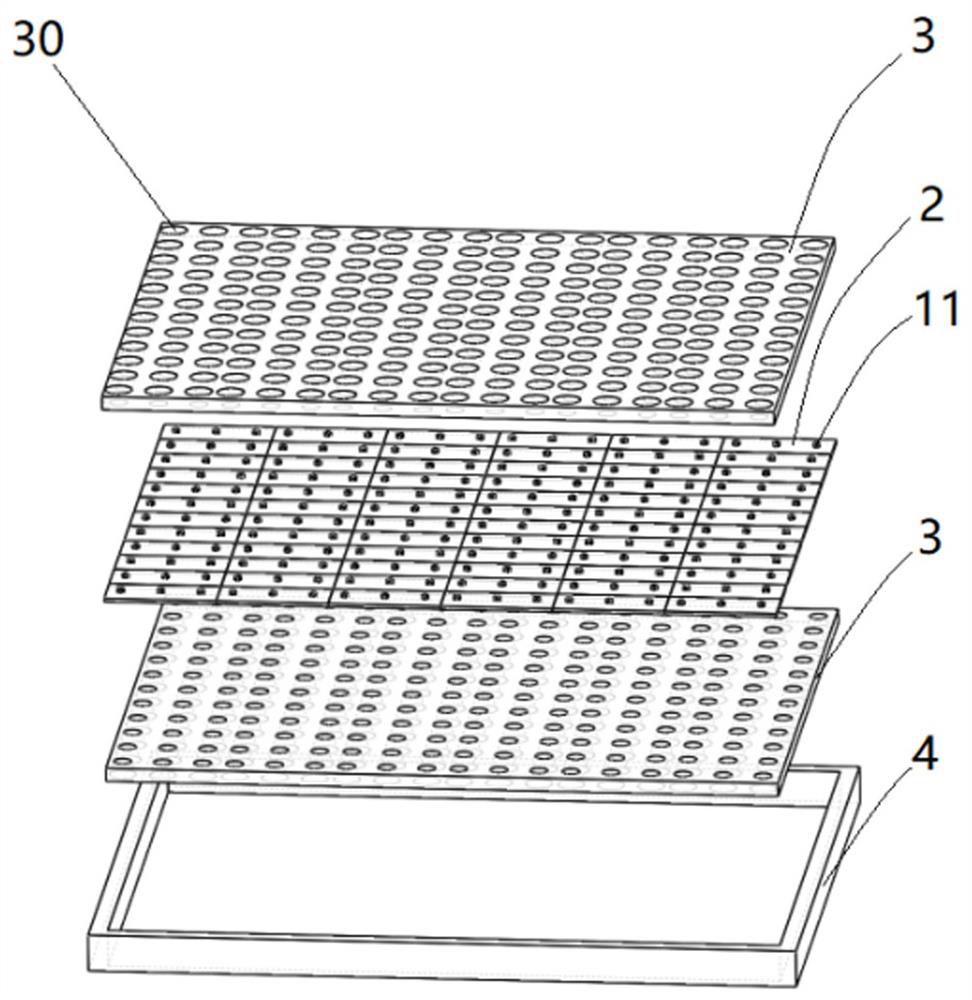

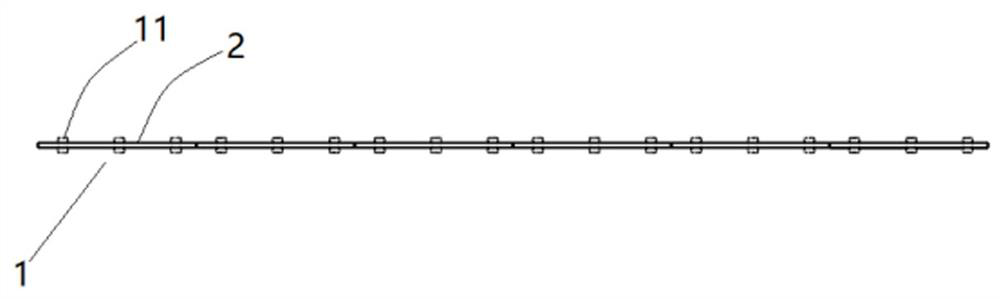

[0040] There are three metal mass blocks 11 in the shape of a round block. There are three metal mass blocks 11 in the form of circular blocks, which can increase the richness of the surface tension area of the viscoelastic film 2, and the area ratio of the metal mass block 11 to the viscoelastic film 2, so as to realize the optimization of frequency noise. noise reduction.

[0041] Except for the above-mentioned distinguishing technical features, please refer to Embodiment 1 for other technical features, which will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com