System for managing pressure in underground cryogenic liquid storage tank and method for the same

A low-temperature liquid and land management technology, applied in the field of pressure systems, can solve the problems of storage tanks being inconveniently buried underground, and achieve the effects of effective pressurization, prevention of storage tank collapse, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

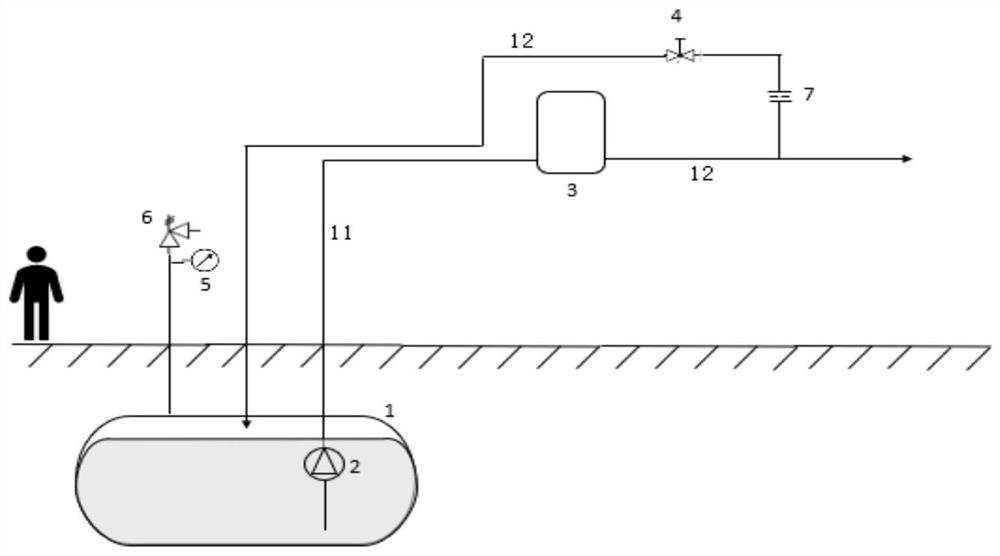

[0050] Such as figure 1 As shown, the first embodiment discloses a system for managing pressure in an underground cryogenic liquid storage tank, comprising: storage tank 1, internal pump 2, evaporator 3, control valve 4, pressure sensor 5, pressure relief valve 6. Restrictor 7, liquid discharge pipeline 11 and steam delivery pipeline 12. Wherein, the storage tank 1 is used to accommodate cryogenic liquid, and there is a headspace above the cryogenic liquid in the storage tank 1, and the headspace is suitable for containing vapor.

[0051] An internal pump 2 is arranged in the storage tank 1, and the internal pump 2 is preferably a submersible pump, which is located below the liquid level of the cryogenic liquid. Alternatively, the internal pump 2 may also be a self-priming pump, the inlet of which is located below the liquid level of the cryogenic liquid. The internal pump 2 of the present invention is not limited to a submersible pump or a self-priming pump, and may also be...

no. 2 example

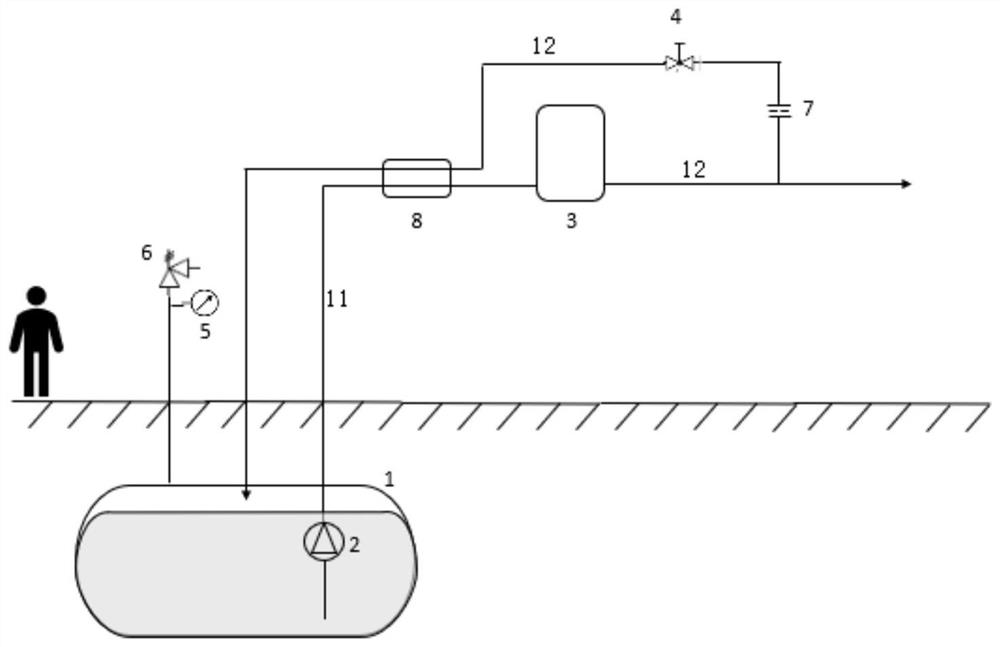

[0063] Such as figure 2 As shown, the second embodiment discloses a system for managing the pressure in an underground cryogenic liquid storage tank, which differs from the first embodiment mainly in the upstream of the evaporator 3 and the downstream of the control valve 4 At the same time, the same heat exchanger 8, preferably a regenerative heat exchanger, is compactly arranged on the pipeline.

[0064] The heat exchanger 8 can cool the warm vapor evaporated by the evaporator 3 by means of a cold high pressure discharge therein or a part of the low temperature liquid discharge pumped by the internal pump 2 upstream of the evaporator 3 . In this way, the thermal load in the storage tank 1 is minimized. In addition, since part of the sensible heat of the cryogenic liquid is removed, the rate of pressure increase in the storage tank 1 is effectively controlled.

no. 3 example

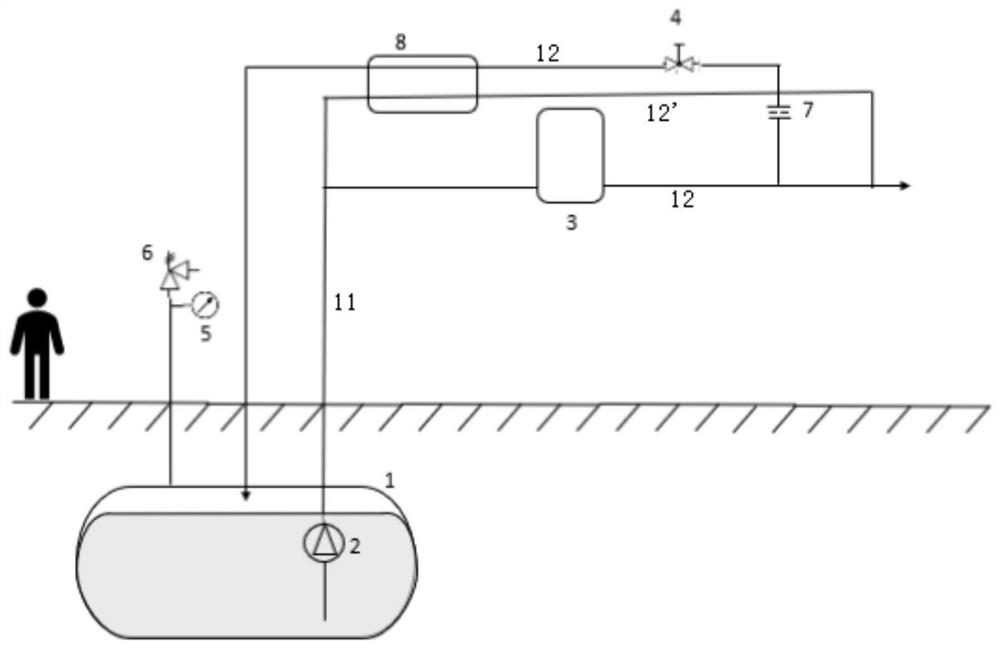

[0066] Such as image 3 As shown, the third embodiment discloses a system for managing the pressure in an underground cryogenic liquid storage tank, the difference from the second embodiment is mainly in the pipeline 12' parallel to the evaporator 3 and the The pipeline downstream of the control valve 4 is also compactly provided with the same heat exchanger 8, preferably a regenerative heat exchanger.

[0067] The heat exchanger 8 can cool the warm vapor evaporated by the evaporator 3 by using part of the cryogenic liquid discharge (for sensible heat management) pumped by the internal pump 2 upstream of the evaporator 3, which part of the discharge directly bypasses the Evaporator3.

[0068] In this way, the heat load in the storage tank 1 is further minimized. In addition, since part of the sensible heat of the cryogenic liquid is removed, the rate of pressure increase in the storage tank 1 is effectively controlled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com