Yarn processing device for seat cover

A processing device and yarn technology, which is applied in the field of yarn processing, can solve the problems of high stress, low yarn strength, and poor quality of seat covers during yarn processing, so as to improve processing efficiency, improve the effect of exhaust dyeing, and avoid precipitation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

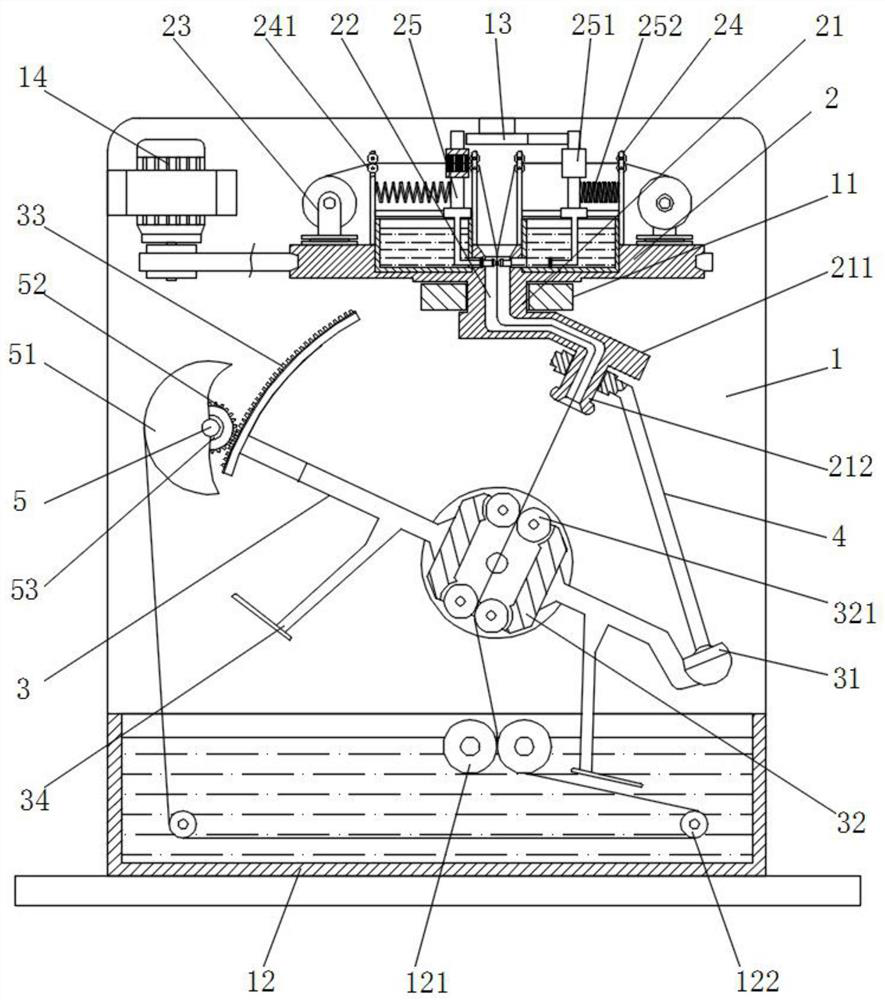

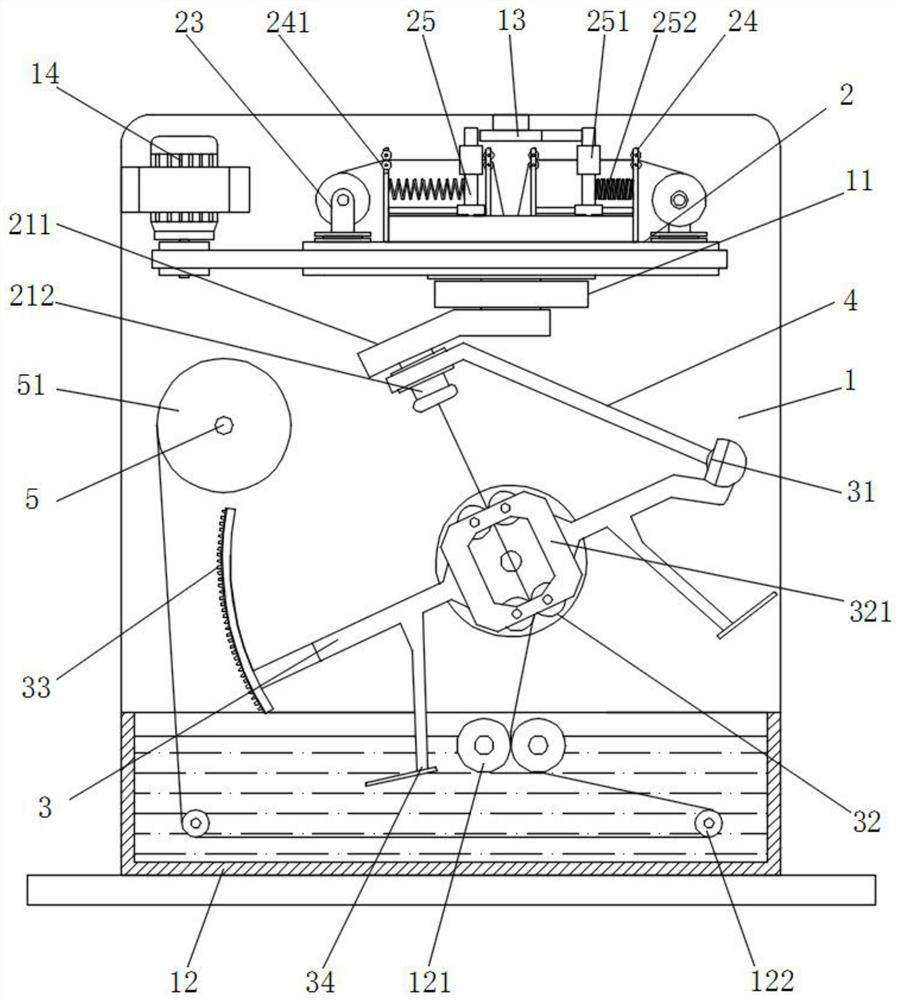

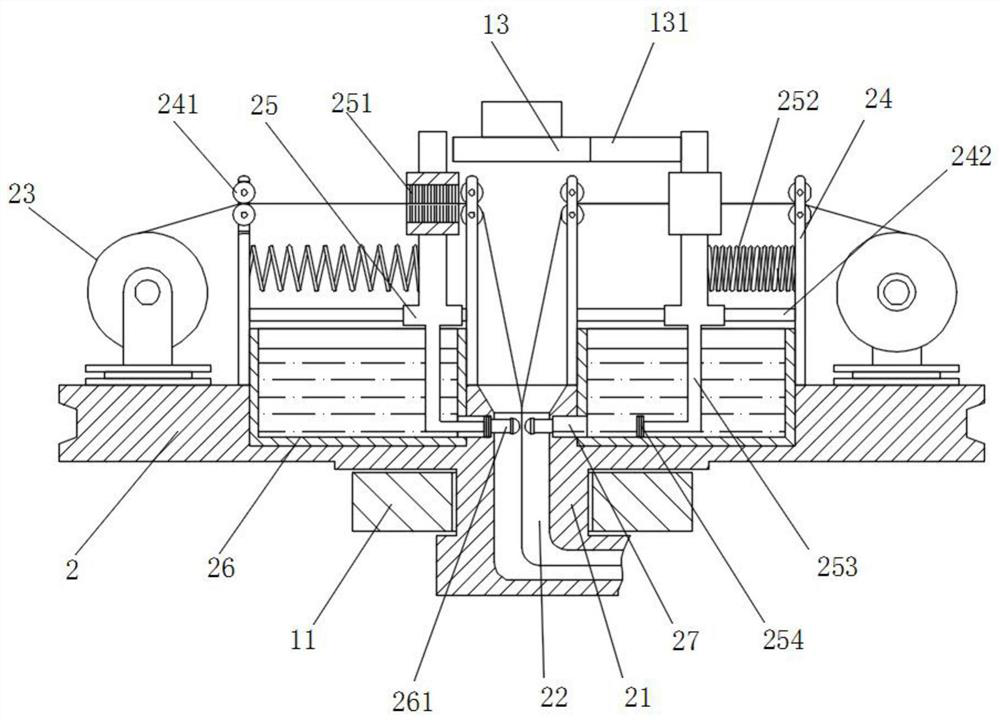

[0027] The technical solutions of the present invention will be better understood in the art, and will be further described in conjunction with the accompanying drawings.

[0028] The present invention provides Figure 1-5 A seating machine, a yarn processing apparatus, including a frame 1, and a rotating seat 11 at the top of the frame 1, the top of the rotating seat 11 is rotated and mounted, and the turn is turned The bottom of the wheel 2 is fixedly connected to the lower convex shaft 21, and the bottom end of the lower convex shaft 21 penetrates the seat 11, and is fixedly connected to the slurry plate 211, and the bottom wall of the slant plate 211 is fixedly connected to its bottom wall vertical setting. The bumps 212, the inner portion of the rotary 2 extends the threading hole 22, which extends from the top of the runner 2 to the bottom of the convex column 212, and there is a plurality of edges of the top of the runner 2. The wire roll 23 is fixed to the position of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com