Active heat management control method and device, vehicle and storage medium

A control method and thermal management technology, applied in the direction of engine control, electronic control of exhaust treatment device, diagnostic device of exhaust treatment device, etc., can solve the problems of lack of environmental factors, active thermal management lack of adaptability to environmental factors, etc. Achieve the effect of improving adaptability and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

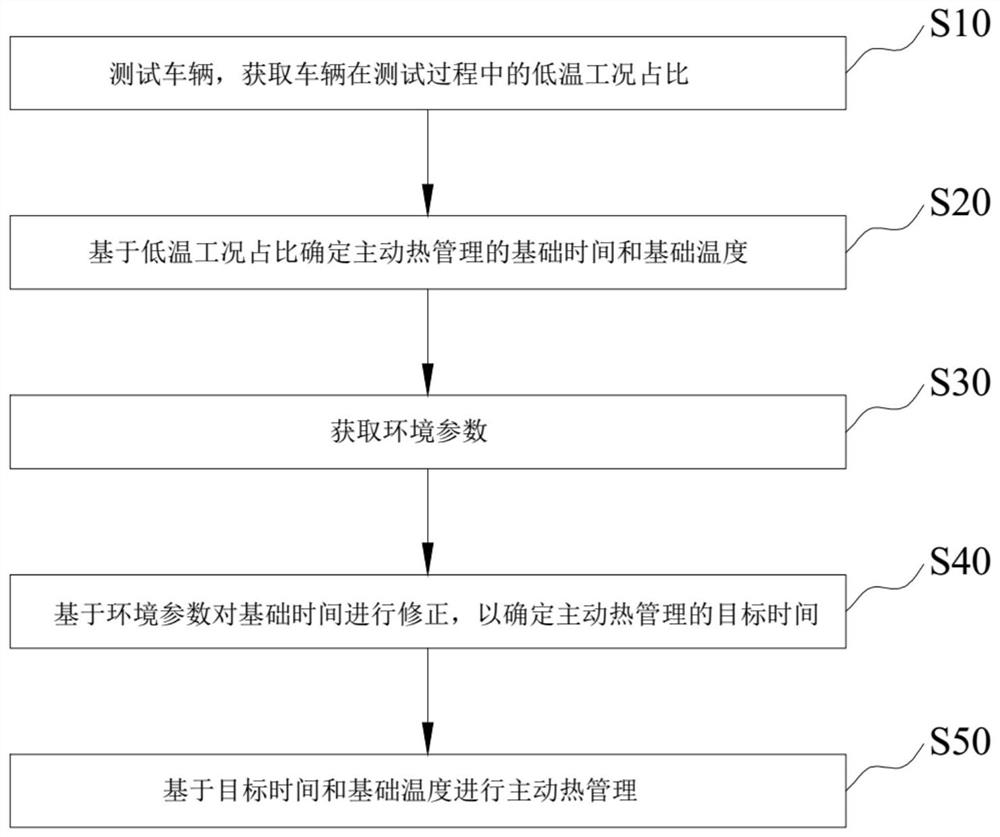

[0062] figure 1 It is a flow chart of an active thermal management control method provided by Embodiment 1 of the present invention. This embodiment is applicable to active thermal management of vehicles to avoid damage to exhaust after-treatment devices. The method can be executed by an active thermal management control device, which can be realized by means of software and / or hardware, and integrated in the vehicle. Specifically, the active thermal management control method includes the following steps.

[0063] S10: Test the vehicle, obtain the proportion of the low temperature condition of the vehicle during the test process. When the vehicle is in the low temperature condition, the actual aftertreatment temperature of the vehicle is lower than the aftertreatment temperature threshold, and the proportion of the low temperature condition is the vehicle in the test process. The ratio of the total time in low temperature conditions to the total time tested.

[0064] It can b...

Embodiment 2

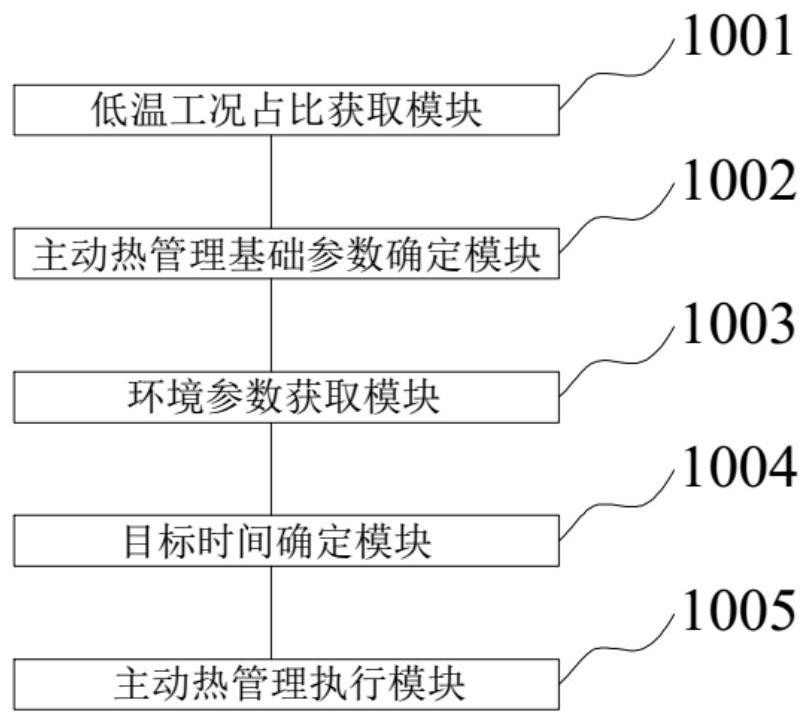

[0096] figure 2 It is a structural diagram of an active thermal management control device provided in Embodiment 2 of the present invention, and the active thermal management control device is used to implement the above active thermal management control method.

[0097]Specifically, the active thermal management control device includes a low temperature operating condition proportion acquisition module 1001 , an active thermal management basic parameter determination module 1002 , an environmental parameter acquisition module 1003 , a target time determination module 1004 and an active thermal management execution module 1005 .

[0098] Wherein, the proportion acquisition module 1001 of the low-temperature working condition is used for acquiring the proportion of the low-temperature working condition of the vehicle during the process of testing the vehicle. The active thermal management basic parameter determination module 1002 is used to determine the basic time and basic t...

Embodiment 3

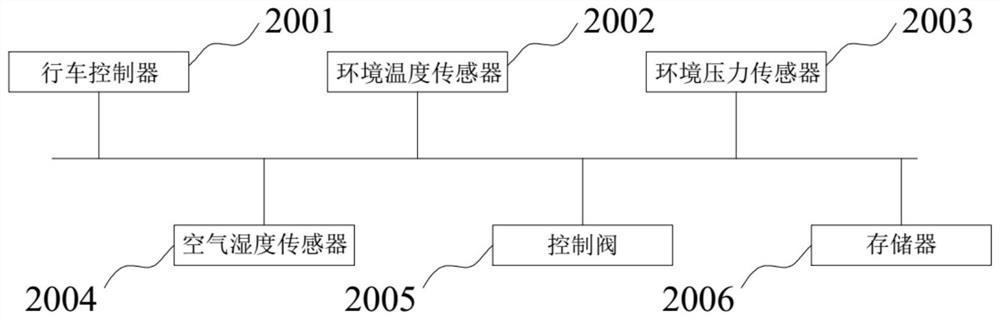

[0105] image 3 The structure diagram of the vehicle provided in the third embodiment includes a driving controller 2001 , an ambient temperature sensor 2002 , an ambient pressure sensor 2003 , an air humidity sensor 2004 , a control valve 2005 and a memory 2006 . Wherein, the traffic controller 2001, the ambient temperature sensor 2002, the ambient pressure sensor 2003, the air humidity sensor 2004, the control valve 2005 and the memory 2006 can be connected through a bus or in other ways. The ambient temperature sensor 2002 is used to collect the ambient temperature and send it to the driving controller 2001; the ambient pressure sensor 2003 is used to collect the ambient pressure and send it to the driving controller 2001; the air humidity sensor 2004 is used to collect the air humidity and send it to the driving controller Controller 2001; control valve 2005, the control valve can control the intake air volume or exhaust volume of the engine, and the control valve can be c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com