Sintering process for producing sintered neodymium-iron-boron magnet

A technology of NdFeB and magnets, which is applied in the direction of magnetic objects, magnetic materials, inductors/transformers/magnets, etc., can solve the problems of heat reduction, damage of NdFeB magnet blocks, and prolonged sintering time, so as to achieve full sintering , uniform heating, uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

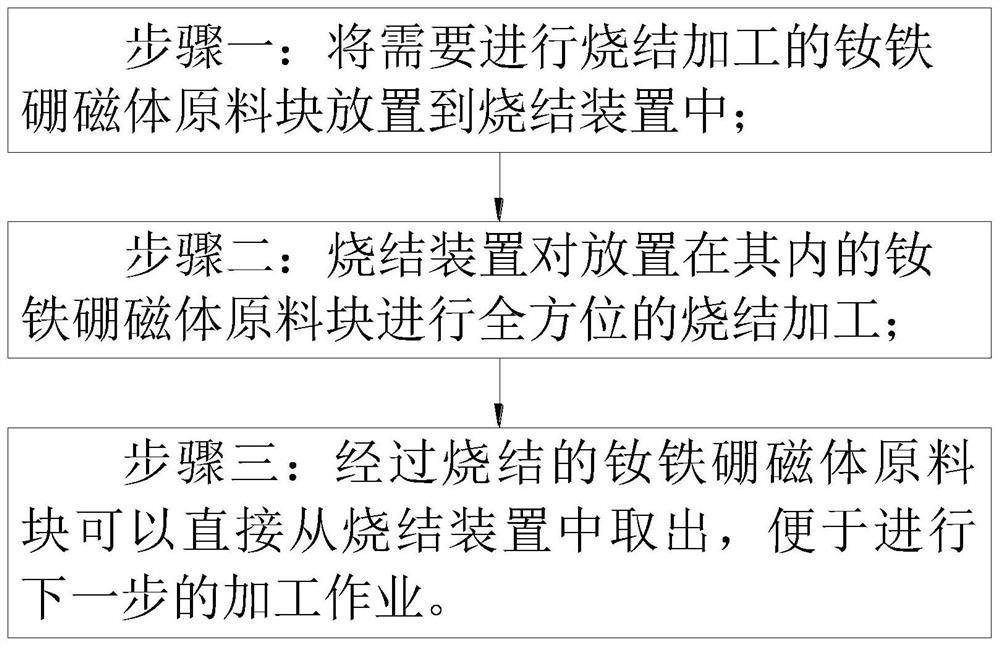

[0031] see Figure 1-8 , the present invention provides a technical solution: a sintering process for the production of sintered NdFeB magnets, the process includes the following steps:

[0032] Step 1: Place the NdFeB magnet raw material blocks that need to be sintered into the sintering device;

[0033] Step 2: The sintering device performs all-round sintering processing on the NdFeB magnet raw material blocks placed in it;

[0034] Step 3: The sintered NdFeB magnet raw material block can be directly taken out from the sintering device, which is convenient for the next processing operation.

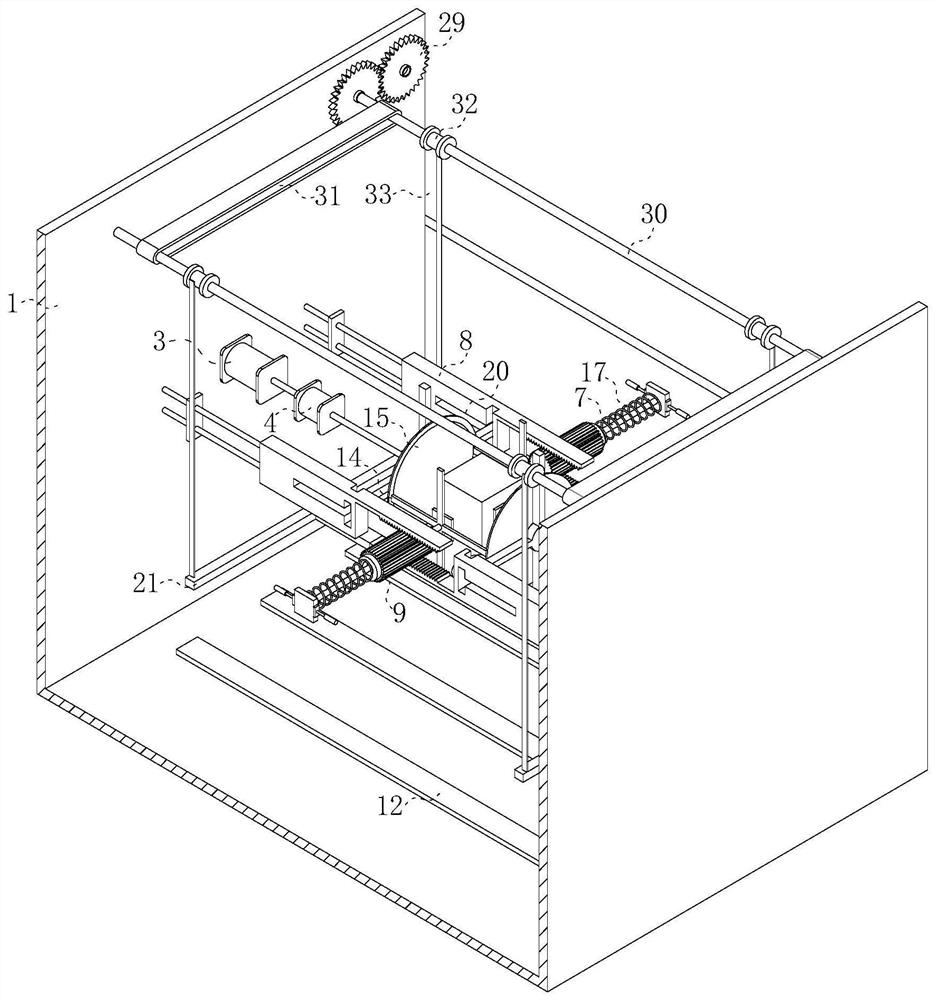

[0035] Please refer to Figure 1-6, the sintering device includes a shell 1, and the shell 1 is provided with a bearing platform 2, the bearing platform 2 is used to place the NdFeB magnet raw material block, and the first clamping assembly is arranged above the bearing platform 2, Through the setting of the first clamping assembly, the NdFeB magnet raw material blocks placed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com