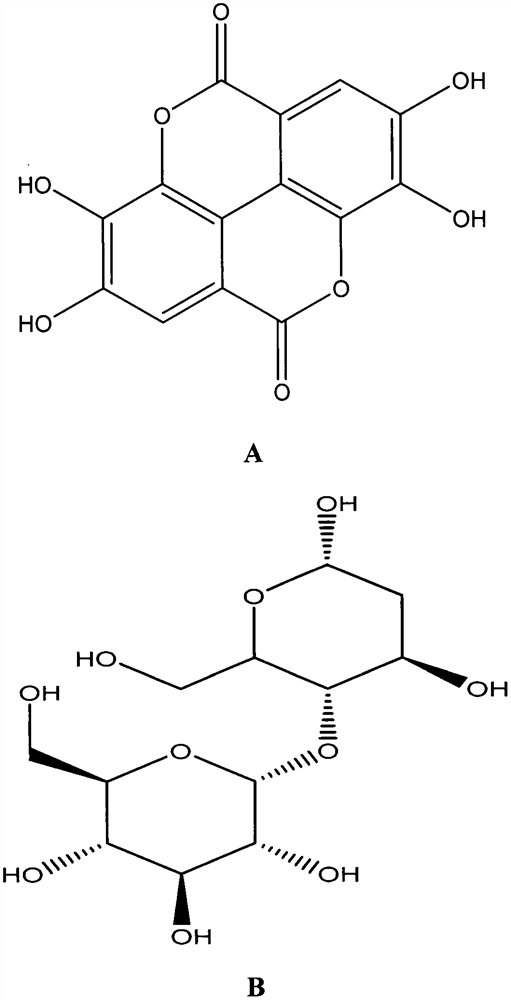

Preparation method of starch-ellagic acid inclusion complex and application of starch-ellagic acid inclusion complex to antioxidant food

A technology for oxidizing food and ellagic acid, which is applied in the food field, can solve the problems of increasing absorption and accelerating body oxidation, and achieves the effects of reducing decomposition, low cost and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

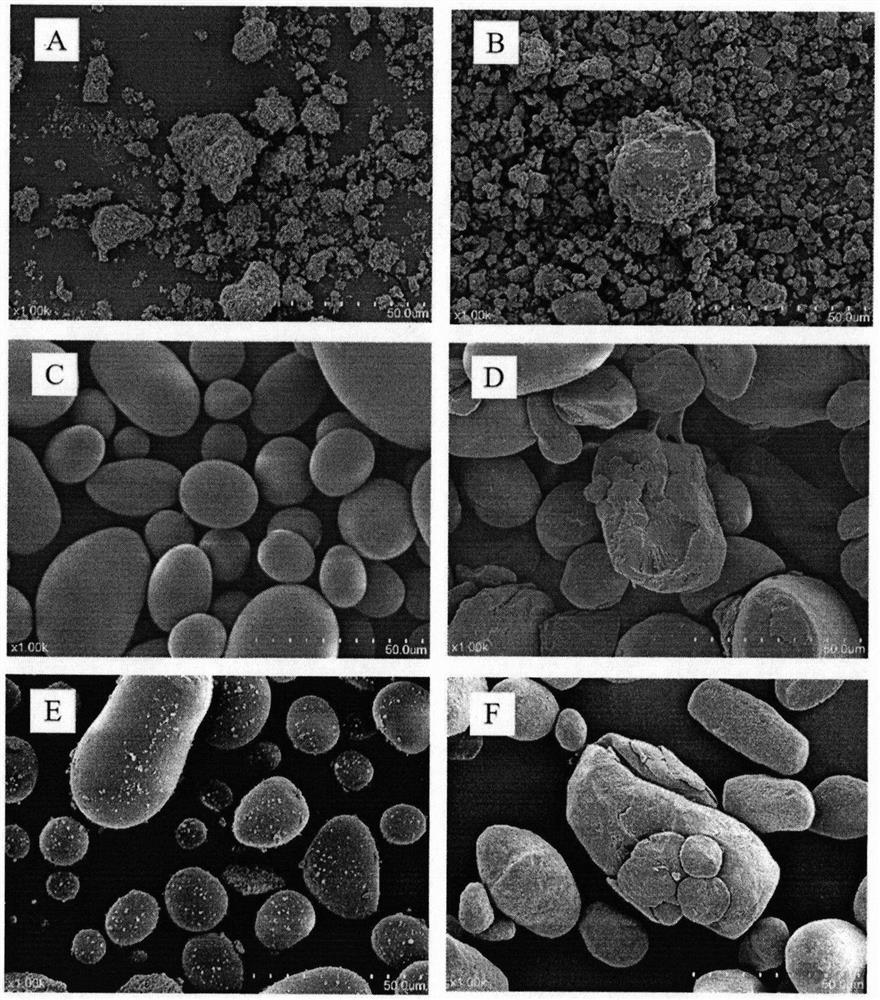

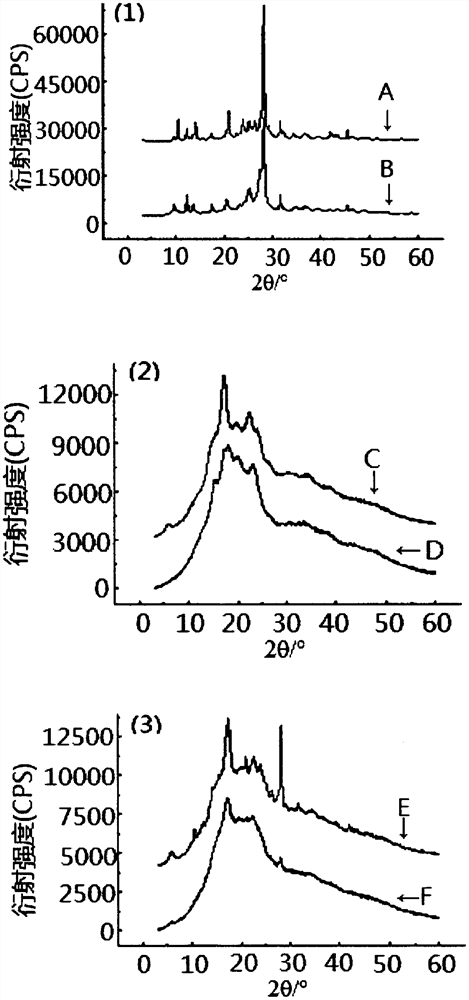

Embodiment 1

[0041]Weigh 10.0g of potato starch and 1.0g of ellagic acid respectively, place them in the ceramic tank of the planetary ball mill, add auxiliary grinding balls of different sizes according to the mass ratio of the ball to the mixture close to 6:1, seal the ceramic tank, and install it in the ball mill , set the rotation speed to 500r / min, and run the ball mill; after the ball mill has been running for 10 hours, pick out the auxiliary grinding balls, take the crude product out of the ceramic tank, and weigh 9.65g. Wash twice with absolute ethanol, each time using 96.5 mL of ethanol, then perform suction filtration, dry the filter cake, weigh 9.23 g, and obtain the starch-ellagic acid inclusion complex. By measuring the content of ellagic acid in the complex, the content of ellagic acid was measured to be 22.0 mg / g; through the sustained release test, it was found that the maximum sustained release rate was about 40%; through the DPPH, ABTS, superoxide anion Determination of f...

Embodiment 2

[0043] Weigh 10.0g of potato starch and 1.0g of ellagic acid respectively, place them in the ceramic tank of the planetary ball mill, add auxiliary grinding balls of different sizes according to the mass ratio of the ball to the mixture close to 6:1, seal the ceramic tank, and install it in the ball mill , set the rotation speed to 700r / min, and run the ball mill; after the ball mill has been running for 20 hours, pick out the auxiliary grinding balls, take the crude product out of the ceramic tank, and weigh 9.25g. Wash twice with absolute ethanol, each time using 92.5 mL of ethanol, then perform suction filtration, dry the filter cake, weigh 9.18 g, and obtain the starch-ellagic acid inclusion complex. By measuring the content of ellagic acid in the complex, the content of ellagic acid was measured to be 20.30mg / g; through the sustained release test, it was found that the maximum sustained release rate was about 37%; through the DPPH, ABTS, superoxide anion Determination of ...

Embodiment 3

[0045] Weigh 10.0g of potato starch and 1.0g of ellagic acid respectively, place them in the ceramic tank of the planetary ball mill, add auxiliary grinding balls of different sizes according to the mass ratio of the ball to the mixture close to 6:1, seal the ceramic tank, and install it in the ball mill , set the rotation speed to 600r / min, and run the ball mill; after the ball mill has been running for 15 hours, pick out the auxiliary grinding balls, take the crude product out of the ceramic tank, and weigh 9.45g. Wash twice with absolute ethanol, each time using 94.5 mL of ethanol, then perform suction filtration, dry the filter cake, weigh 9.14 g, and obtain the starch-ellagic acid inclusion complex. By measuring the content of ellagic acid in the complex, the content of ellagic acid was measured to be 20.6mg / g; through the sustained release test, it was found that the maximum sustained release rate was about 39%; through the DPPH, ABTS, superoxide anion Determination of f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com