Stent and preparation method thereof

A technology of helical direction and metal wire, applied in the field of stents, can solve the problems of easy mutual slippage, unable to ensure the close combination and mechanical matching of the reinforced film and the stent, loss of recyclability, etc., to achieve the effect of improving radial support.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] A method of preparing a bracket, the specific steps are as follows:

[0058] (1) According to the weft processes, the radiometric (25 mm having a needle diameter is 25mm, the needle number is 22 needles), resulting in a single wire (diameter of 0.12 mm) from a cylinder of the nuckel alloy. The tubular bracket, the tissue structure of the cylindrical tubular bracket is a weft flat needle tissue, and the length of the cylindrical stent is 120 mm, the inner diameter is 20 mm;

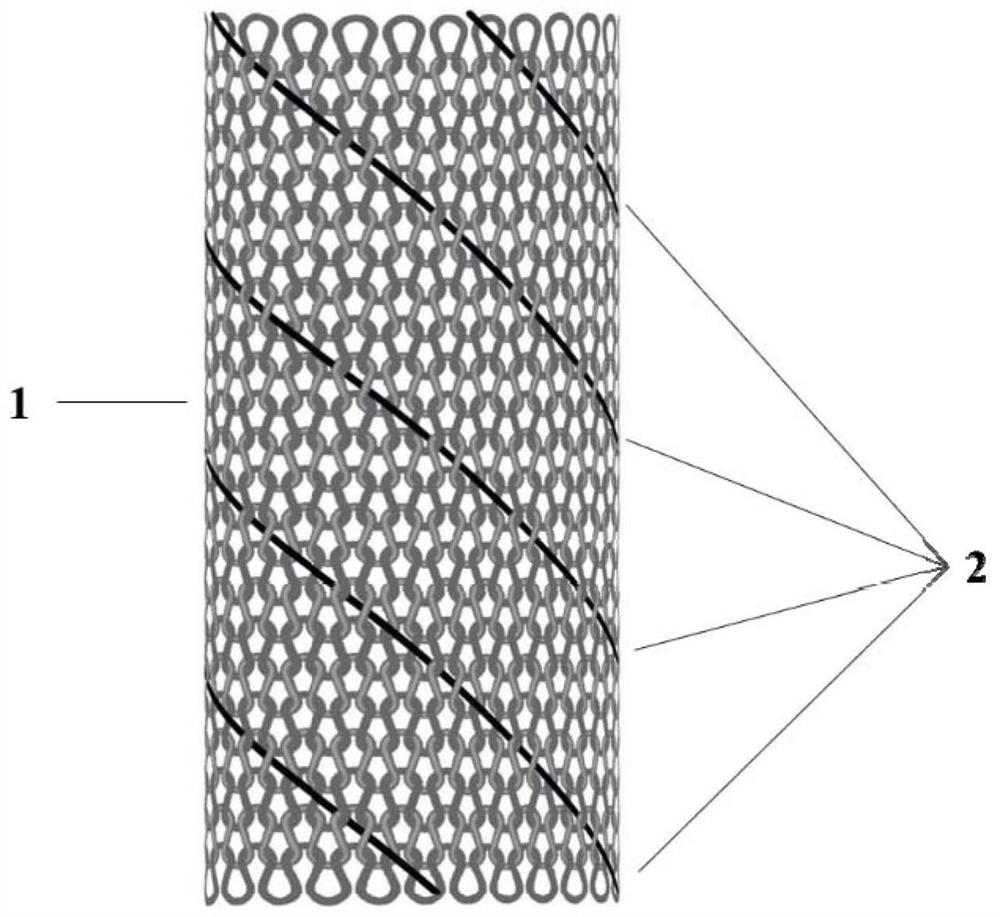

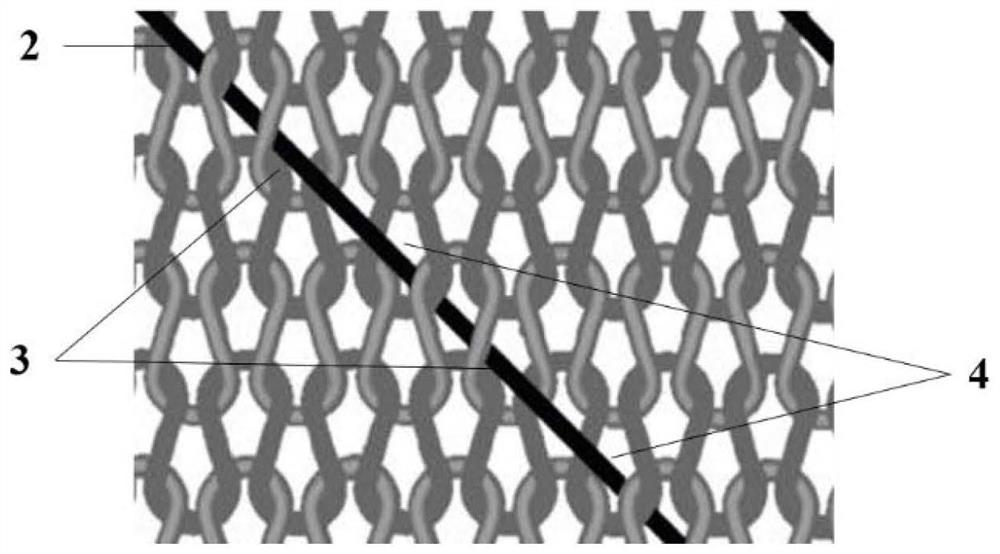

[0059] (2) figure 1 and figure 2 As shown, 4 wires of the nickel-titanium alloy (same, 0.20 mm) are used according to the pitch (60 mm), the number (4), the spiral direction (all inverse) and the wear cycle ( The cycle, n is the coil longitudinal column between the spiral metal wire 2 penetration position 3 and the wear position 4, and m is the coil cross column between the spiral metal wire 2 penetration position 3 and the wearing position 4, N And M Part 1) requires spiral feed into the cylindrical t...

Embodiment 2

[0063] A method of preparing a bracket, the specific steps are as follows:

[0064] (1) According to the weft processes, the radial molter (a needle diameter of 20 mm, the number of needles is 15 needles) is used in a single metal wire (diameter of 0.12 mm) to obtain a cylinder. The tubular support, the tissue structure of the cylindrical tubular stent is a weft flat needle tissue, and the length of the cylindrical stent is 150 mm and an inner diameter of 18 mm;

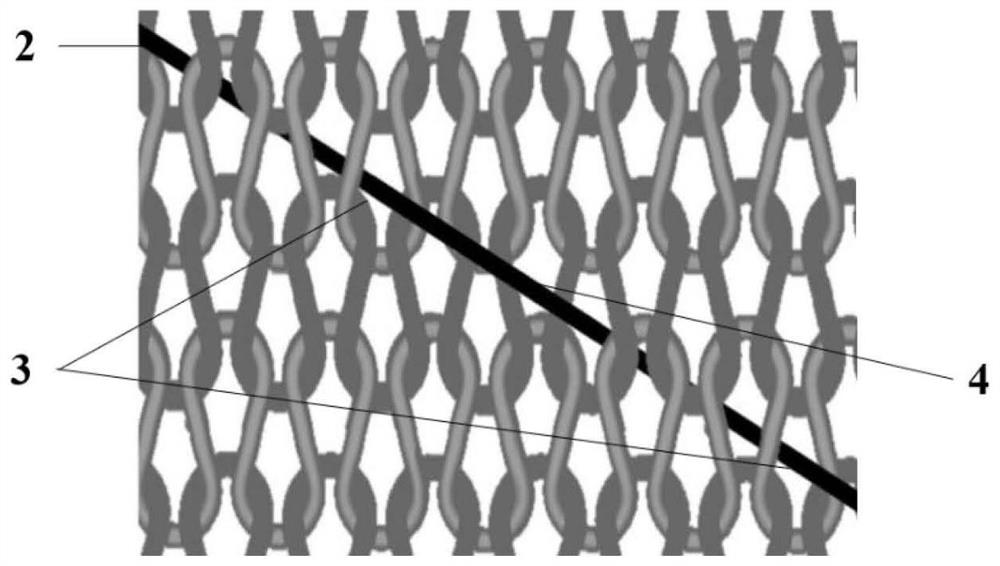

[0065] (2) image 3 As shown, 2 wires of the nickel-titanium alloy (same, 0.15 mm) are used according to the pitch (70 mm), the number (2), and the spiral direction (all inverse) and the wear cycle ( The cycle, n is the coil longitudinal column between the spiral metal wire 2 penetration position 3 and the wear position 4, and m is the coil cross column between the spiral metal wire 2 penetration position 3 and the wearing position 4, N The requirement of 2, m is 1), spirally fed into the cylindrical tubular bracket 1, s...

Embodiment 3

[0069] A method of preparing a bracket, the specific steps are as follows:

[0070] (1) According to the weft processes, the radius diameter (20 mm, the needle is 25 mm, the number of needles is 25 needles), resulting in cylindrical tubular shaping (diameter 0.14 mm) The tissue structure of the stent, the cylindrical tubular stent is the weft ribbed tissue, the length of the cylindrical tubular bracket is 100mm, the inner diameter is 18 mm; the single strand wire is formed together by 2 wires;

[0071] (2) Single wire (diameter of 0.30 mm) of medical stainless steel (5.30 mm) according to the pitch (50 mm), the number of roots (1), the spiral direction (正) and the wear cycle ( The cycle, n is a coil longitudinal column between the spiral metal wire and the wear position, m is a coil cross column number, n and m between the helical wire punctum, and the wear position. The need to spirally fed the cylindrical tubular bracket specified in the settled arc in the wearing position, so ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com