Preparation method of sterilizing and mildew-proof carriage plate and logistics vehicle carriage

A technology of carriage board and logistics vehicle, applied in the field of carriages, can solve the problems of poor sterilization effect and coating peeling off of material carriages, and achieve the effects of light weight, excellent antibacterial performance and good sterilization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Weigh the polycondensation product of epichlorohydrin and bisphenol A and aromatic polyamine according to the ratio of 100:25, heat to 260°C, and fully mix to obtain the resin;

[0025] Adding nano-sized zinc oxide with a particle size of less than 30nm to the resin, and the added amount of nano-sized zinc oxide is 5% of the weight of the resin;

[0026] After mixing the resin and the fiber cloth according to the weight ratio of 30:70, use infrared heating and curing to 200°C for 20 minutes to obtain the car panel.

Embodiment 2

[0028] Weigh the polycondensation product of epichlorohydrin and bisphenol A and aromatic polyamine according to the ratio of 100:30, heat to 200°C, and fully mix to obtain the resin;

[0029] Adding nano-sized zinc oxide with a particle size of less than 30nm to the resin, and the added amount of nano-sized zinc oxide is 5% of the weight of the resin;

[0030] After the resin and the fiber cloth are mixed according to the weight ratio of 40:60, they are cured by infrared heating to 200°C for 20 minutes to obtain the car panel.

[0031] Observation of the compartment panels prepared in Examples 1-2 shows that the surface roughness of the compartment panels prepared in Example 1 is lower than that of the compartment panels prepared in Example 2.

experiment example 1

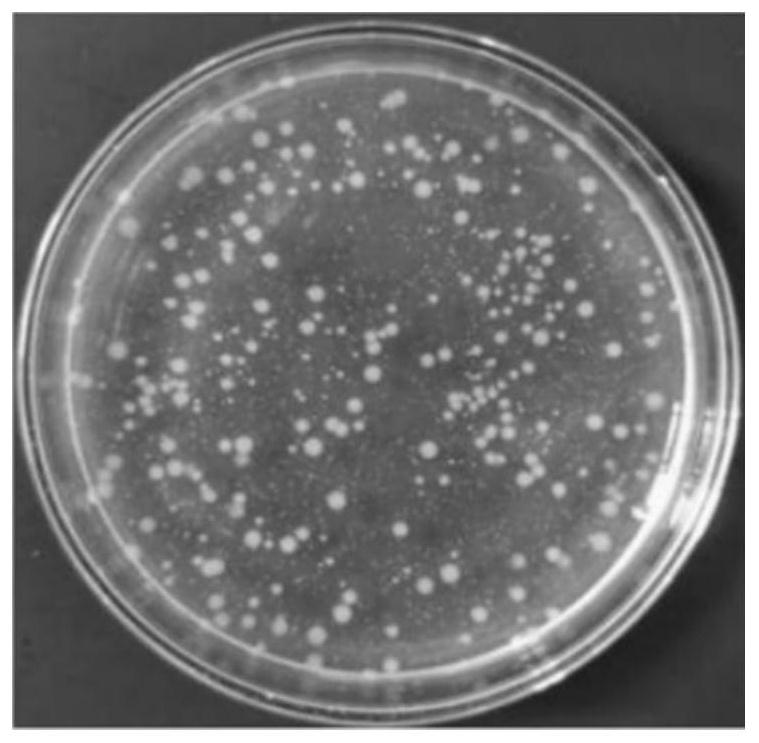

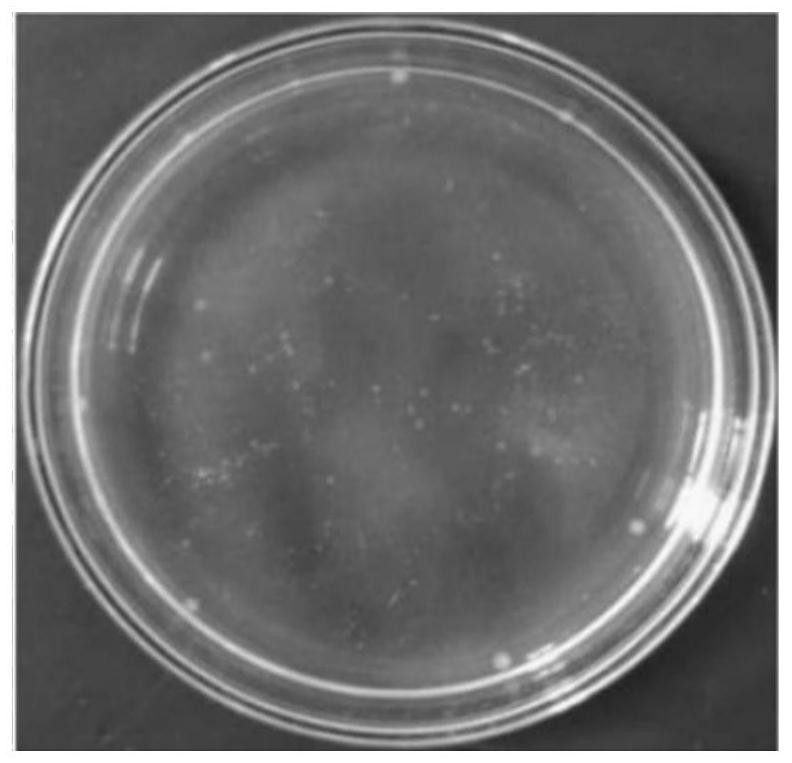

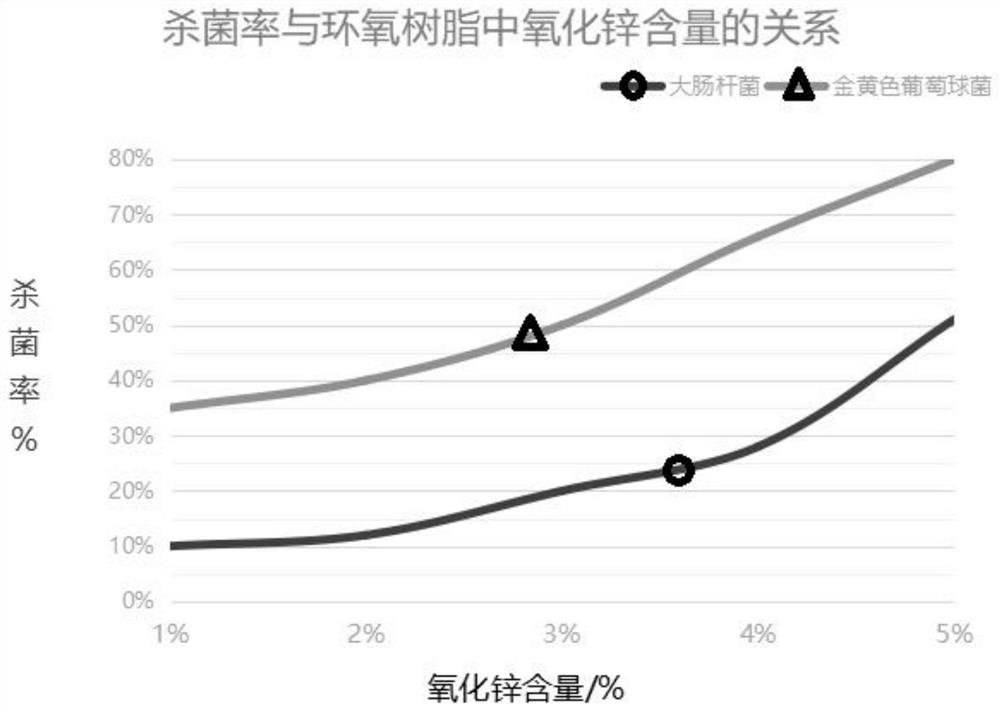

[0034] First, mix the pre-cultured Escherichia coli liquid with the nano-zinc oxide suspension prepared at a concentration of 1%, and then use a shaker to vibrate for 15 minutes, then take a specified volume of the solution and apply it evenly on the experimental utensils, and the set of utensils Together with the control vessel without zinc oxide, put it in a constant temperature room with a temperature of 37 ° C and a relative humidity of 90%, take it out after standing for 24 hours, and observe and see if the experimental vessel is as good as it is. figure 2 As shown, the control vessel such as figure 1 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com