Asphalt warm mixing agent

A technology of warm mix agent and asphalt, which is applied in the field of asphalt warm mix agent, can solve the problems of reducing the high temperature viscosity of asphalt, the influence of asphalt low temperature viscosity without paying attention, and the scarcity of warm mix agent, so as to achieve the improvement of low temperature viscosity, great application value, Effect of lowering viscosity at high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

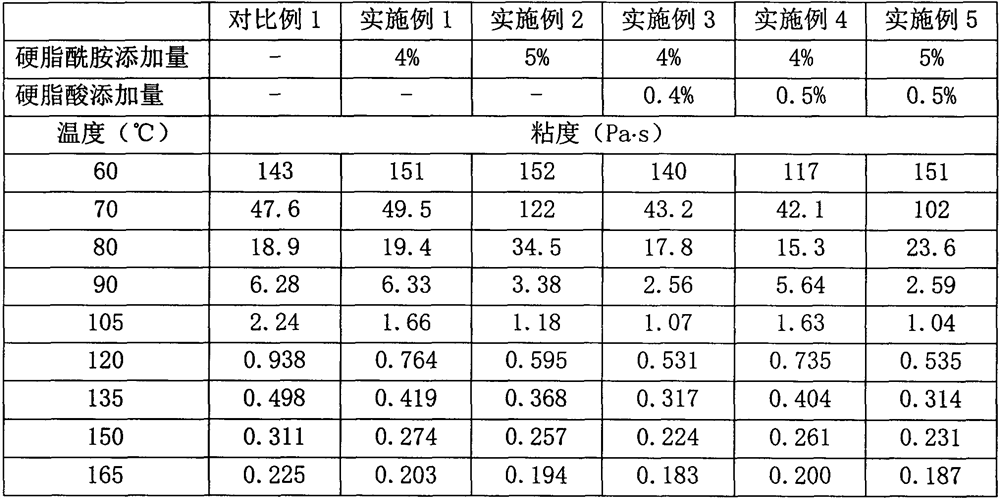

[0011] Weigh 20.0g of base asphalt in a 100ml small beaker, heat it in an oven at 100°C, add 0.80g of stearamide after the base asphalt is melted, stir with a stainless steel stirring rod for about 6 minutes, stearamide is completely dissolved, and then Pour the asphalt mixture into the preheated Brookfield viscosity measurement mold, and then measure the viscosity of the asphalt mixture at 60-165°C with a Brookfield rotational viscometer according to the method specified in the "Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering" (JTG E20-2011). Viscosity, experimental data are listed in the summary table.

Embodiment 2

[0013] Weigh 20.0g of base asphalt in a 100ml small beaker, heat it in an oven at 100°C, add 1.00g of stearamide after the base asphalt is melted, stir with a stainless steel stirring rod for about 6 minutes, stearamide is completely dissolved, and then Pour the asphalt mixture into the preheated Brookfield viscosity measurement mold, and then measure the viscosity of the asphalt mixture at 60-165°C with a Brookfield rotational viscometer according to the method specified in the "Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering" (JTG E20-2011). Viscosity, experimental data are listed in the summary table.

Embodiment 3

[0015] Weigh 20.0g of base asphalt in a 100ml small beaker, heat it in an oven at 100°C, add 0.80g of stearamide and 0.08g of stearic acid after the base asphalt is melted, and stir it with a stainless steel stirring rod for about 6 minutes. The amide and stearic acid are completely dissolved, and then the asphalt mixture is poured into the preheated Brookfield viscosity measurement mold, and then the Brookfield rotational viscosity is measured according to the method specified in the "Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering" (JTG E20-2011). Measure the viscosity of the asphalt mixture at 60-165°C with the meter, and the experimental data are listed in the summary table.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com