Method for foam separation of beta-glucosidase fusion protein

A glucosidase and fusion protein technology, which is applied in the directions of glycosylase, fusion polypeptide, chemical instruments and methods, etc., can solve the problems of inability to complete the separation and purification of β-Glu, low yield and purification multiple, complicated operation process, etc. Achieve the effect of low cost, simple operation and improved separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] (1) Induced expression of fusion protein GLEGB

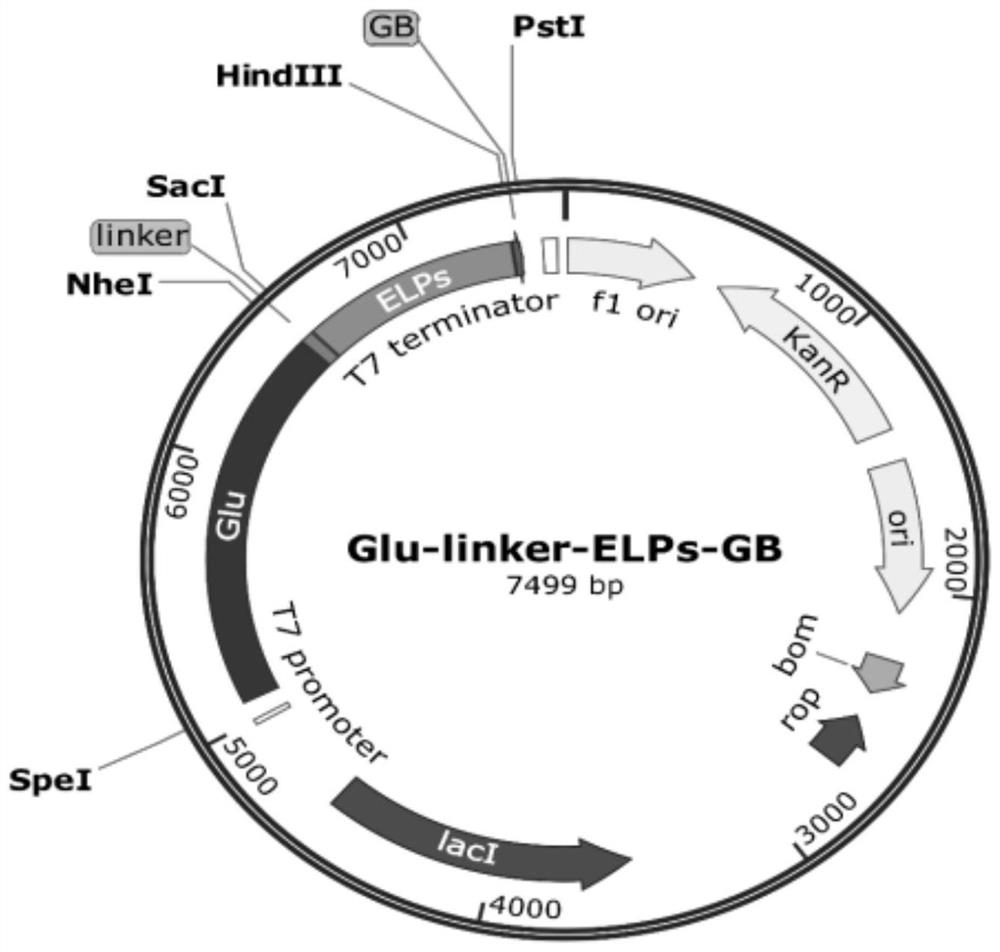

[0078] Coded and designed ELP amino acid sequence, denoted as ELP(VPGVG)50, inserted into GB polypeptide, linked to Glu with connecting peptide linker, and constructed recombinant plasmid pET-GLEGB(Glu-linker-ELP-GB).

[0079] figure 1 It is a schematic diagram of the structure of the recombinant plasmid pET-GLEGB (containing ELP and GB tags).

[0080] The amino acid sequence of the Glu is shown in SEQ.ID.NO.1; the amino acid sequence of the linker is shown in SEQ.ID.NO.2; the amino acid sequence of the ELP is shown in SEQ.ID.NO.3 ; The amino acid sequence of GB is shown in SEQ.ID.NO.4. Each amino acid sequence is as follows:

[0081] SEQ.ID.NO.1(Glu):

[0082]MDDVDNDTLVTFPDDFKLGAATASYQIEGGWDADGKGPNIWDTLTHERPHLVVDRSTGDVADDSY HLYLEDVRLLKDMGAEVYRFSISWARILPEGHDNNVNEAGIEYYNKLIDALLRNGIEPMVTMYHWDLPQ KLQDLGGWPNRILAKYAENYARVLFSNFGDRVKQWLTFNEPLTFMDAYASDTGMAPSVDTPGIGDYLTA HTVILAHANIYRLYEREFREEQQGQVGIALNIHWCEPETGSPKDVEACERYQQFNL...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com