Aluminum alloy pedestrian overpass

A pedestrian bridge and aluminum alloy technology, applied in bridges, truss bridges, bridge forms, etc., can solve the problems of high transportation cost, heavy structure, low plasticity, etc., achieve good overall continuity, fast and convenient assembly, and ensure integrity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

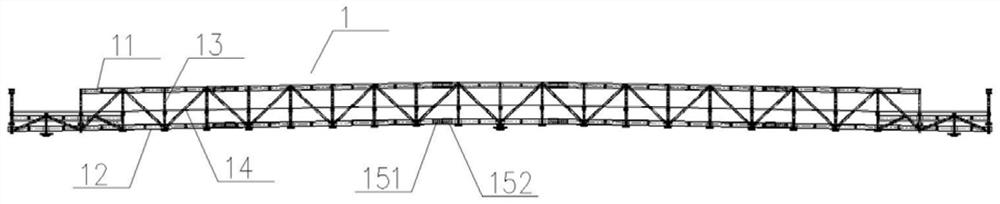

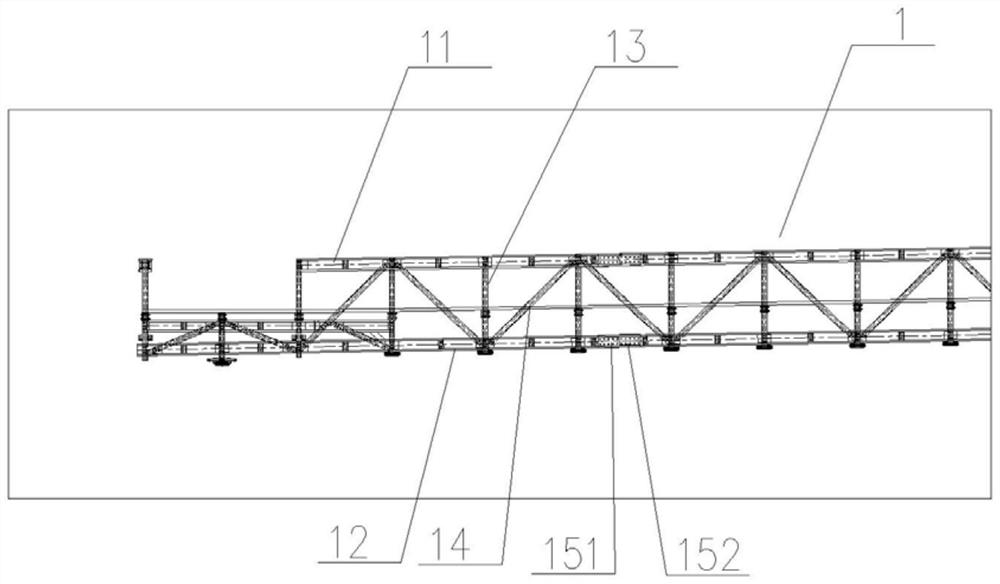

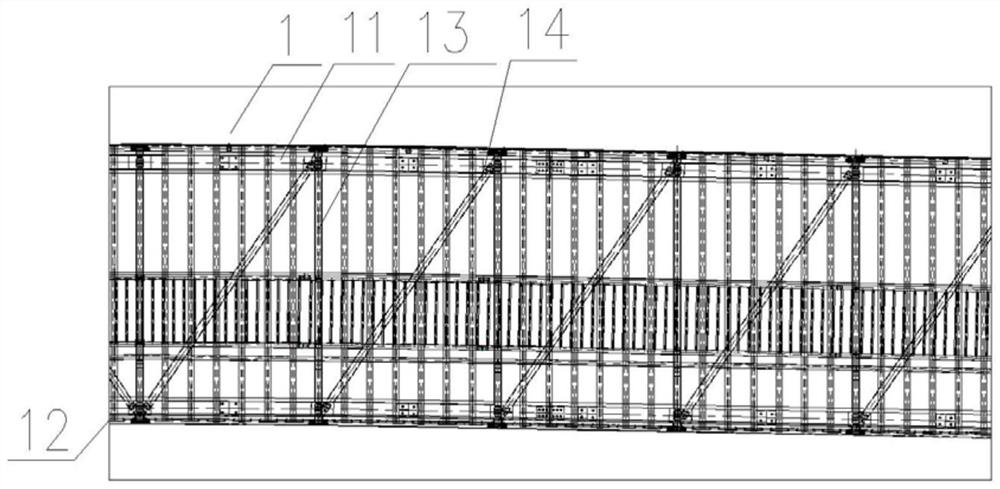

[0058] Attached below Figure 1-22 , the present invention will be described in detail.

[0059] like Figure 1-18 As shown, an embodiment of the present invention: an aluminum alloy pedestrian bridge, including supporting piers, a bridge body structure and a staircase structure made of aluminum alloy materials, several stairway straight bars 3, installed on the stairway straight bars 3. The stairway top stringer 64 at the top, the stairway ceiling 62 installed on the top of the stairway top stringer 64, several decorative grid bars 5 installed on the outside of the bridge body and the stairway, and the bridge body ceiling 61 are respectively arranged on The bridge body handrails and stairway handrails on the two inner sides of the bridge body and the two inner sides of the stairway. The bridge body structure includes at least two groups of truss body units 1 spliced by connecting plates and bolts. Each group of truss body units 1 includes several groups of The horizontal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com