Driving device for open-air down-the-hole drill

A technology of down-the-hole drilling rigs and driving devices, which is applied in the direction of drilling driving devices in boreholes, rotary drilling rigs, earthwork drilling, etc., and can solve problems such as poor lubrication of the box, unstable rotation, and gear fluid leakage. Achieve stable rotation, low cost, and avoid grease leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

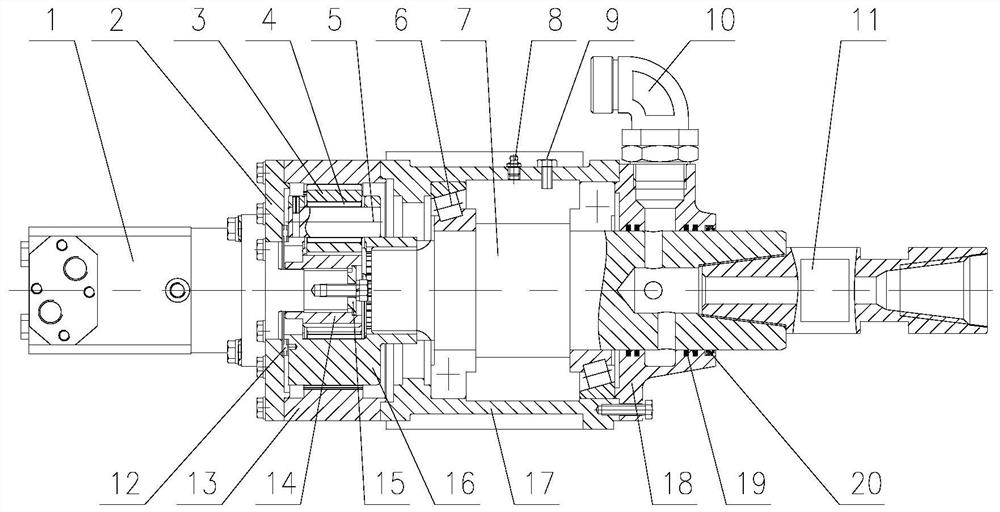

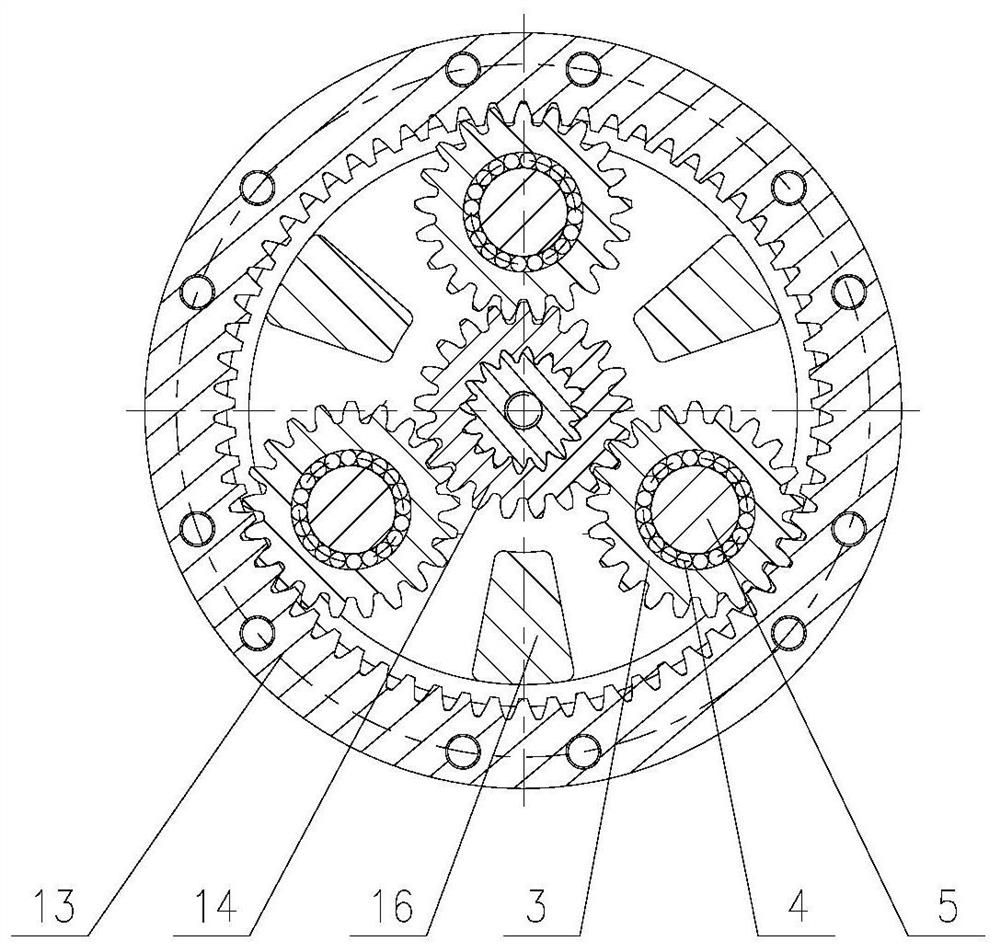

[0021] Such as figure 1 , figure 2 The driving device for a surface down-the-hole drilling rig shown includes a sun gear 14; the power of the sun gear 14 is connected to the hydraulic motor 1, and the sun gear 14 meshes and drives a plurality of planetary gears 3 to form a planetary gear set, and the planetary gears 3 drive The planetary carrier 16 rotates, and the planetary carrier 16 is coaxially connected with the rotary main shaft 7, and the front end of the rotary main shaft 7 is equipped with a drill pipe joint 11.

Embodiment 2

[0023] Based on Embodiment 1, the rotary spindle 7 is installed in the machine base 17, and the tapered roller bearing 6 is set on the rotary spindle 7 in the machine base 17 so that there is a cavity between the machine base 17 and the rotary spindle 7, and the cavity passes through the air pipe The joint 10 communicates with the outside of the machine base 17 .

Embodiment 3

[0025] Based on Embodiment 2, a front cover 18 is installed at the front end of the base 17 , and the inner pipe space of the gas pipe joint 10 passes through the front cover 18 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com