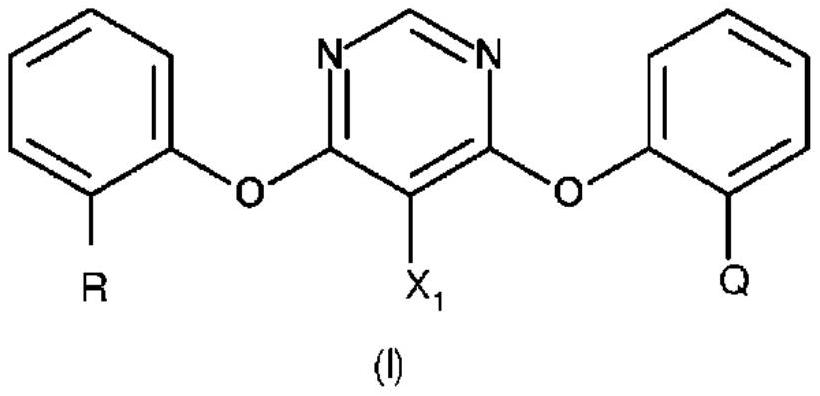

Process for the preparation of fungicidally active strobilurin compounds and intermediates thereof

A compound and halogen technology, applied in the field of preparation of intermediates that can be used to prepare the strobilurin compound, can solve problems such as complex separation procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

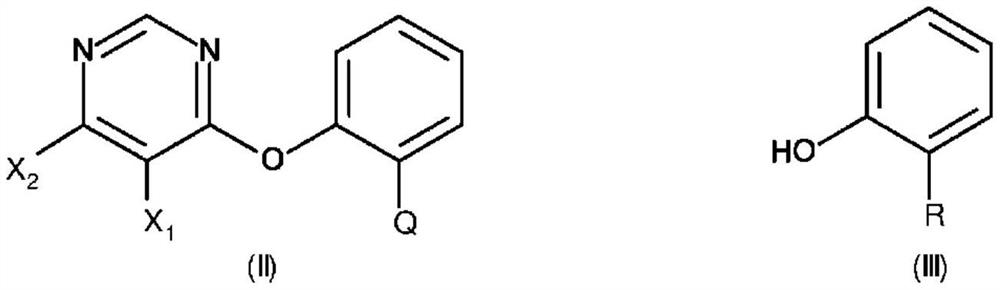

[0442] (E) Preparation of methyl 2-{2-[6-chloropyrimidin-4-yloxy]phenyl}-3-methoxyacrylate (IIa):

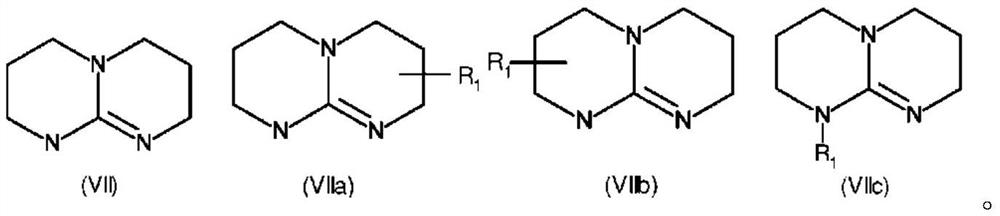

[0443] At 10 °C, 4,6-dichloropyrimidine (98%, 92 g, 0.605 mol) was added to 3-(methoxymethylene)-2(3H)-benzofuranone (97%, 91 g, 0.5 mol) in a stirred mixture in methyl formate (275 g). At 10 °C to 15 °C, 1,5,7-Triazabicyclo[4.4.0]dec-5-ene (0.035 g, 0.25 mmol, 0.05 mol%) was added to the reaction mixture followed by dropwise addition of methanol Sodium (30% in methanol, 110 g, 0.61 mol). After the addition, the reaction mass was stirred at 10°C to 15°C for 1 hour. The methyl formate was then distilled off while keeping the temperature below 55°C. Toluene (300ml) and water (200ml) were added to the residue, and the mixture was stirred at 60°C to 65°C. The mixture was cooled to room temperature, and the organic layer was separated. The solvent was distilled off from the reaction mixture under reduced pressure, and the oily residue was heated to 130°C to 135°C. Potassium bis...

Embodiment 2

[0444] Embodiment 2 (comparative example)

[0445] Preparation of (E)-methyl 2-{2-[6-chloropyrimidin-4-yloxy]phenyl}-3-methoxyacrylate (IIa) in the absence of catalyst:

[0446] To a stirred mixture of 3-(methoxymethylene)-2(3H)-benzofuranone (97%, 91 g, 0.5 mol) in methyl formate (275 g) was added 4, 6-Dichloropyrimidine (98%, 92 g, 0.605 mol). Sodium methoxide (30% in methanol, 110 g, 0.61 mol) was added dropwise to the reaction mixture at 10°C to 15°C. After the addition, the reaction mass was maintained at 10°C to 15°C for 1 hour. The methyl formate was distilled at atmospheric pressure while maintaining the temperature below 55 °C. To the residue were added toluene (300 mL) and water (200 mL), and the mixture was heated at 60°C to 65°C. The mixture was cooled to room temperature, and the organic layer was separated. Toluene was distilled off under reduced pressure, and the oily residue was heated at 130°C to 135°C to remove the solvent. Potassium bisulfate (1.36 g, ...

Embodiment 3

[0448] Preparation of azoxystrobin (Ia)

[0449] At room temperature, methyl (E)-2-{2-[6-chloropyrimidin-4-yloxy]phenyl}-3-methoxyacrylate (83.5g, 0.25mol), potassium carbonate (52.8 1,5,7-triazabicyclo[4.4.0]dec-5-ene ( 0.695 g, 0.005 mol, 2.0 mol%) in DMF (10 mL). The mixture was heated to 90°C and stirred at the same temperature for 7 to 8 hours. The reaction mixture was cooled to 50°C to 55°C and filtered to remove salts. DMF was distilled at 70°C to 80°C under vacuum. The residual material was crystallized from a mixture of methanol (90 mL) and water (10 mL) to give the product (98% purity, 0.78% dimer content).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com