Multi-stage cooling and purifying device for cracked oil gas

A purification device, oil and gas technology, applied in the field of waste cracking, can solve the problems of oil quality decline, different oil and gas components, complex components, etc., to achieve comprehensive utilization, improve cracking efficiency, and realize the effect of waste heat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

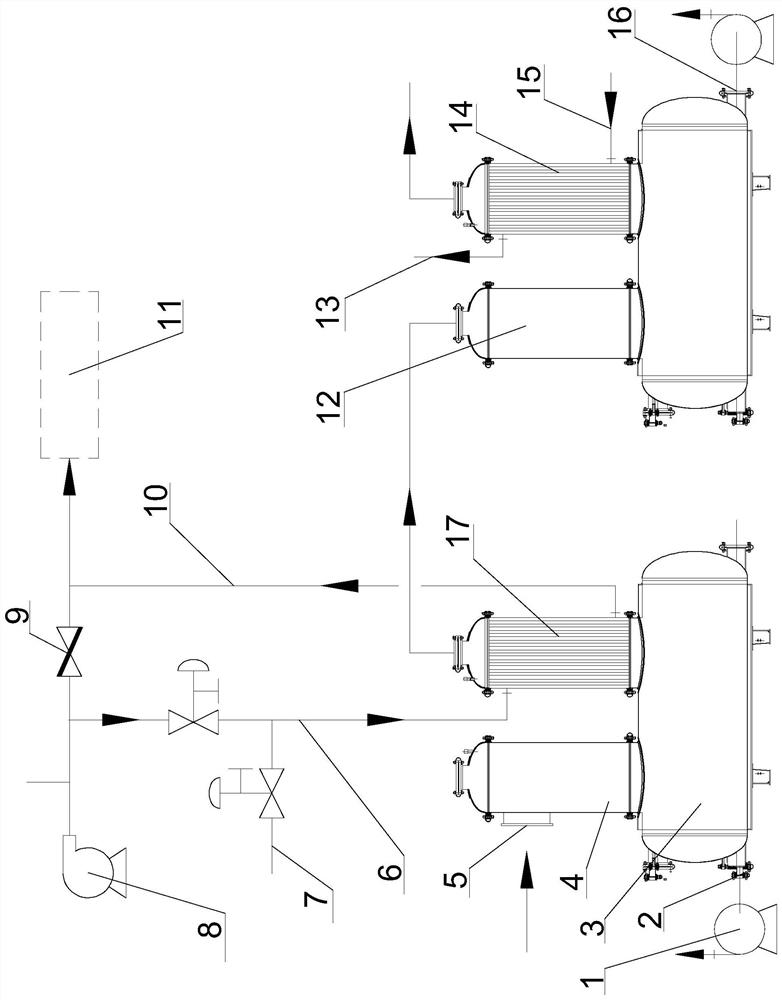

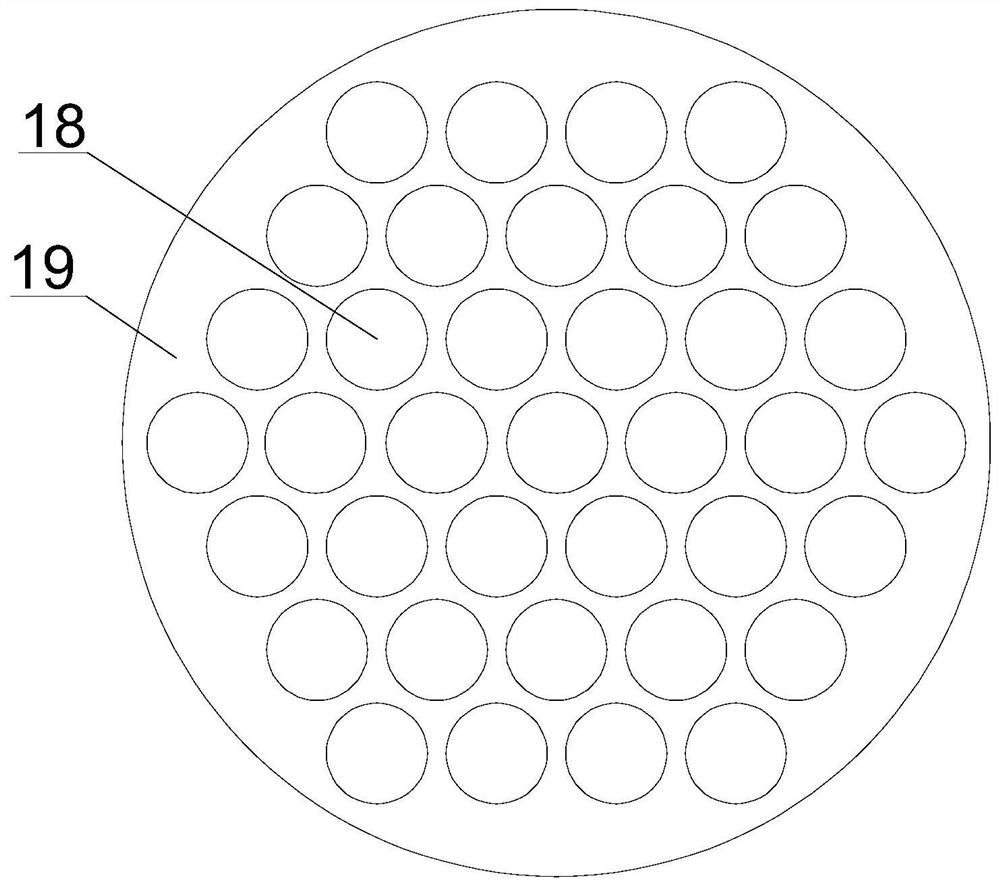

[0022] Such as figure 1 and 3 As shown, a multi-stage cooling and purification device for cracking oil and gas, the device includes a first cooler and a second cooler arranged in series. The two coolers have the same structure, and both include horizontally arranged oil storage tanks. There are oil-gas inlet tower and oil-gas condensing tower. The oil-gas condensing tower is provided with a condensing pipeline 18, and a cooling cavity 19 is set outside the condensing pipeline 18. The cooling cavity is connected with a cooling medium inlet and a cooling medium outlet, and the oil and gas enter the oil-gas condensing tower. Then move upward along the condensing pipeline;

[0023] Wherein the side of the first oil-gas inlet tower 4 is provided with a first oil-gas inlet 5, and a flue gas circulation device is connected to the first oil-gas condensation tower 17; the flue gas circulation device includes a flue gas inlet pipe 6 and a flue gas return pipe 10, and The gas inlet pip...

Embodiment 2

[0027] The process of using the multi-stage cooling and purification device for cracking oil and gas described in Example 1 to carry out the cooling and purification of oil and gas, the specific process is as follows:

[0028]The high-temperature oil vapor from the cracker enters the first oil and gas inlet tower through the first oil and gas inlet, and fills the tower body, and finally presses down into the first oil storage tank to contact with the pre-installed oil in the oil storage tank, and elute through it For the solid components, since the oil in the oil storage tank is not fully loaded, there is a cavity at the top of the first oil storage tank to facilitate the movement of oil and gas, and the oil and gas after preliminary elution enter the first oil and gas condensation tower;

[0029] At this time, the high-temperature flue gas, which is the heat source of the cracker, enters the flue gas inlet pipe through the heat recovery circulating fan, and at the same time, b...

Embodiment 3

[0032] The process of using the multi-stage cooling and purification device for cracking oil and gas described in Example 1 to carry out the cooling and purification of oil and gas, the specific process is as follows:

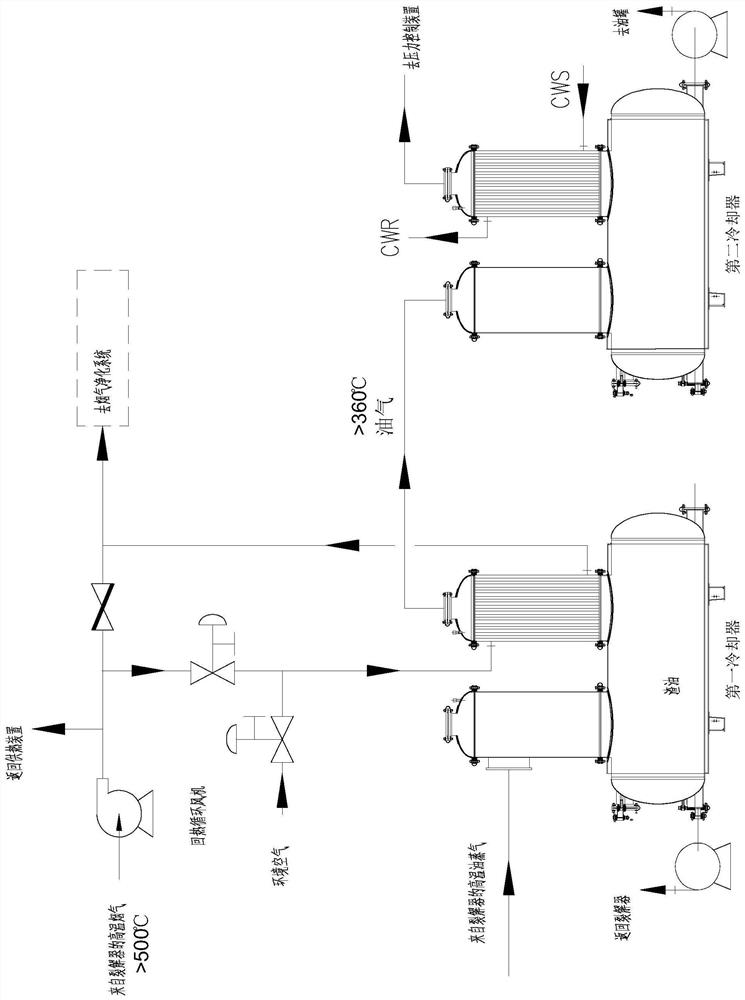

[0033] like figure 2 As shown, the high-temperature oil vapor from the cracker enters the first oil-gas inlet tower through the first oil-gas inlet, fills the tower body, and finally presses down into the first oil storage tank to contact with the pre-installed oil in the oil storage tank. It elutes the solid components in it. Since the oil in the oil storage tank is not fully loaded, there is a cavity on the top of the first oil storage tank to facilitate the movement of oil and gas. After the initial elution, the oil and gas enter the first oil and gas condensation tower;

[0034] At this time, the high-temperature flue gas, which is the heat source of the cracker, enters the flue gas inlet pipe through the heat recovery circulating fan, and at the same tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com