Weighing and water adding system of asphalt mixing station

An asphalt mixing and mixing bin technology, which is applied in mixers, mixer accessories, dissolving and other directions, can solve problems such as affecting the accuracy of water addition and large errors, and achieve the effects of improving water adding efficiency, high degree of automation, and increasing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

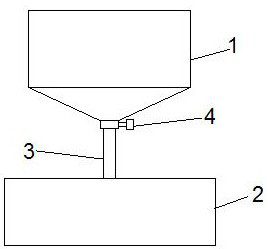

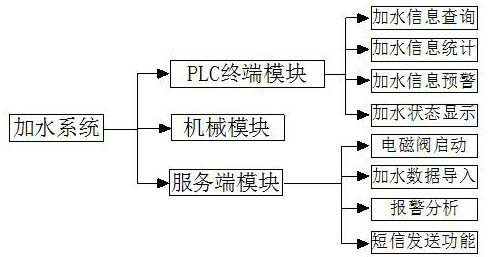

[0039] Such as Figure 1-3 As shown, a weighing and adding water system of an asphalt mixing station includes a mechanical module, a PLC terminal module, and a server module; the mechanical module includes a water storage bin 1, a mixing bin 2, a downpipe 3, and a solenoid valve 4; There is a downpipe between the warehouses, the downpipe is provided with a solenoid valve, and the solenoid valve is controlled by a PLC terminal module; the PLC terminal module controls the terminal module to include water filling information query, water filling information statistics, water filling information warning, water filling Status Display;

[0040] The server module includes solenoid valve start, water addition data import, alarm analysis, and short message sending; the server also includes a flow monitoring system, which includes a data acquisition module, a control module, and a data transmission module. The data acquisition module includes a flow rate monitoring system. sensor, PLC ...

Embodiment 2

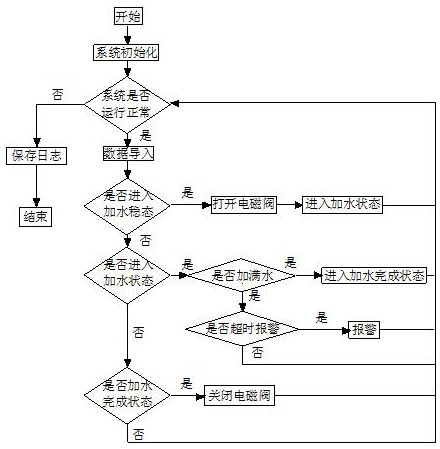

[0045] Such as Figure 3-6 As shown, on the basis of Embodiment 1, a method for adding water to the weighing water adding system of an asphalt mixing plant includes the following steps: S1, according to the ratio of materials and water, enter the amount of water added through the PLC controller;

[0046] S2, the system detects whether it is running normally, imports the water adding data into the server module, and controls to open the solenoid valve to add water, after the processing of the PLC preset program, and monitors the flow of the downpipe in real time through the flow monitoring system, and obtains the water adding time;

[0047] S3, the PLC terminal module judges whether the system is in the state of adding water, and when the water is added to the preset time, the system automatically closes the solenoid valve to complete the water addition; if the water adding time exceeds the preset water adding time, the alarm device is activated to give an alarm, and the alarm d...

Embodiment 3

[0050] On the basis of Embodiment 2, the data analysis module specifically includes the following steps a, data feature extraction, segmenting the flow data obtained by the data acquisition card, and then performing feature extraction for each section of flow data, selecting time domain, Data characteristics in frequency domain and time-frequency domain; b. Establish a database, process the data characteristics in layers according to the flow rate of the sewer pipe, and use a clustering algorithm to find the cluster center for the signals of each layer, and obtain a small number of data sets. A small number of data sets are recorded for classification training, and the training results are extracted and stored in the database; c, the new database is layered, and for the new database, firstly calculate the data center of each cluster through clustering, and then compare with the database established in b Take the Euclidean distance between the cluster centers of each layer, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com